Where Are Diesel Jeans Manufactured?

- Share

- publisher

- Elowen

- Issue Time

- Sep 27,2025

Summary

Discover the origins of Diesel jeans and learn where these iconic denim pieces are manufactured. Uncover the craftsmanship behind your favorite styles.

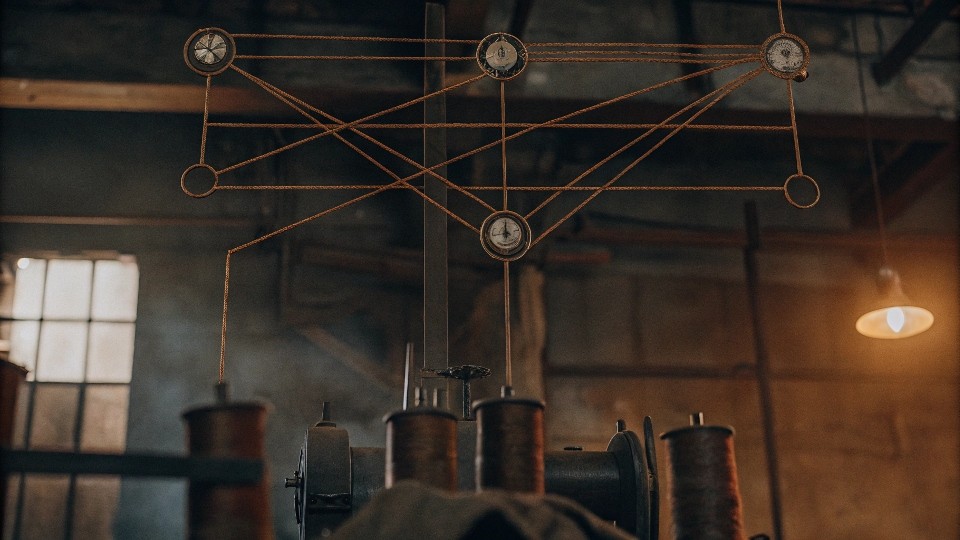

Jeans are more than just clothing; they’re a statement of identity, a blend of craftsmanship and culture woven into every seam. For over four decades, Diesel has built its reputation on edgy designs, innovative washes, and a rebellious spirit that resonates with fashion-forward consumers worldwide. But behind those iconic leather patches and signature rivets lies a complex global network of factories, each contributing its own heritage, expertise, and standards of quality. Whether you’re hunting for authenticity or simply curious about where your favorite pair was born, understanding Diesel’s production footprint can deepen your appreciation for the brand—and help you make more informed choices next time you click “add to cart.”

Diesel jeans are manufactured across multiple countries, including Italy, Turkey, China, and the United States. Italy remains the heart of high-end, artisanal production—especially for premium lines and limited editions. Turkey supplies a significant volume of mid‐range collections with competitive pricing and skilled denim workers. China handles part of the mass‐market output and specialized treatments, while select washes and vintage finishes occasionally occur in the U.S., particularly for domestic specialty runs.

Imagine tracking the journey of your jeans—from raw cotton fields to artisanal Italian workshops, to cutting and washing facilities in Turkey, to that moment you first slip them on. That’s exactly what we’ll explore. Stay with us as we peel back the layers of Diesel’s manufacturing map, reveal country‐by‐country insights, and show you how custom specialists like DiZNEW fit into the high‐end denim puzzle.

Which Countries Host Diesel’s Denim Factories?

Diesel operates a diversified production network spanning Italy, Turkey, China, and the United States. Italy is the flagship hub for premium collections and innovative washes, leveraging centuries‐old textile traditions. Turkey serves as a cost‐effective center for volume production with a strong denim manufacturing ecosystem. China contributes to both mainstream and specialized lines, benefiting from advanced finishing techniques and economies of scale. The U.S. hosts limited domestic runs, primarily for exclusive washes and quick‐turn collections.

Italy: The Artisanal Heartbeat

• Why Italy Matters: Italy’s denim heritage dates back to the early 19th century. Cities like Prato and Conegliano house ateliers known for hand‐applied treatments—paint splatters, laser distressing, and eco‐conscious washes. Diesel’s most exclusive lines, including their “Handcrafted Selection,” are often produced in these facilities to guarantee that signature premium feel.

• Craftsmanship & Innovation: Italian artisans blend traditional shuttle looms with cutting‐edge waterless finishing technologies. This marriage of old and new preserves fabric integrity while reducing water footprint by up to 90%. Diesel frequently collaborates with these mills to develop proprietary denim blends—such as indigo‐infused stretch fabrics—that maintain shape and color longevity.

Turkey: The Industry Workhorse

• Scale & Speed: Turkey boasts over 600 textile and garment factories that specialize in denim production. Its geographical proximity to Europe reduces lead times and shipping costs—key factors when Diesel needs quick replenishment for seasonal collections.

• Skilled Workforce: Turkish denim workers undergo rigorous training in dyeing, sanding, and hand‐washing techniques. On average, a Turkish denim operator completes 35 wash steps per garment, ensuring consistency across batches. This level of expertise makes Turkey Diesel’s go‐to for both core ranges and mid‐tier premium offerings.

China: The Specialized Powerhouse

• Mass Production Meets Innovation: China remains a cornerstone for Diesel’s volume needs. With an estimated 50% of Diesel’s total output passing through Chinese facilities, brands capitalize on high‐volume spinning, weaving, and sophisticated finishing lines.

• Advanced Wash Technologies: From ozone fading to 3D laser engraving, Chinese factories invest heavily in automation. Diesel leverages these capabilities to experiment with avant‐garde finishes at scale—think gradient dip‐dye effects or embedded graphic prints.

United States: The Limited Edition Frontier

• Domestic Runs for Premium Markets: While less than 5% of Diesel’s total production occurs in the U.S., those jeans often carry a “Made in USA” label that commands a premium. Factories in California and North Carolina focus on small‐batch, artisanal wash treatments—such as stone‐washing with local river stones or hand‐applied resin coatings.

• Market Appeal: U.S.‐made denim resonates strongly with domestic shoppers and specialty retailers who prioritize “locally made” credentials and faster turnaround times.

| Country | Approx. % of Total Production | Key Strengths | Typical Products |

Italy | 30% | Artisanal craftsmanship, eco‐tech washes | Premium lines, limited editions |

| Turkey | 35% | Cost‐effective, skilled wash operators | Core collections, mid‐tier premium jeans |

| China | 50% (overlaps with others) | High‐volume spinning, advanced finishing | Mass‐market lines, experimental finishes |

| USA | <5% | Small‐batch precision, “Made in USA” branding | Limited editions, quick‐turn specialty runs |

Where Is Diesel Manufactured?

A straightforward question with a multifaceted answer: Italy, Turkey, China, and the U.S. collectively host Diesel’s denim operations, each chosen for a unique mix of heritage, cost structure, technology, and market proximity.

Is Diesel Made in China?

Yes. China accounts for roughly half of Diesel’s global output. The brand leverages Chinese spinning, weaving, and finishing capabilities to achieve economies of scale and cutting‐edge wash effects at competitive prices.

Is Diesel Made in the USA?

Select Diesel collections—especially limited editions and exclusive washes—are produced in U.S. workshops, primarily in California and North Carolina. These small‐batch runs emphasize domestic craftsmanship and faster delivery to North American retailers.

Are Any Jeans Manufactured in the USA?

Absolutely. U.S.‐made Diesel jeans represent less than 5% of overall production but command a premium niche, prized for their “Made in USA” authenticity and artisanal wash techniques.

Why Does Diesel Choose These Manufacturing Locations?

Diesel’s site selection balances cost efficiency, technical expertise, logistical convenience, and brand positioning. Italy offers artisanal heritage and eco‐innovation. Turkey supplies volume at competitive rates with skilled workforce capabilities. China enables large‐scale production with advanced machinery and specialty finishes. The U.S. serves domestic markets seeking “Made in USA” authenticity and rapid turnarounds. Strategic trade agreements, proximity to key markets, and environmental regulations further influence Diesel’s global factory map.

Cost Structures & Labor Expertise

• Italy commands premium wages—up to 35–40 euros per hour for skilled denim artisans—but justifies it with unparalleled craftsmanship and brand prestige.

• Turkey’s labor rates hover around 8–12 euros per hour, offering a sweet spot between cost and skill level. Turkish operators are renowned for executing complex wash sequences accurately and efficiently.

• China’s vast labor pool provides a continuum from low‐cost basic assembly (3–5 euros per hour) to highly specialized finishing technicians earning upwards of 15 euros per hour, depending on skillsets and certifications.

Infrastructure, Logistics & Trade Agreements

• European hubs like Italy and Turkey benefit from EU trade agreements, streamlining customs and VAT processes when shipping within Europe.

• Proximity to major ports—La Spezia (Italy), Izmir (Turkey), Shanghai and Shenzhen (China), Long Beach and Savannah (USA)—reduces shipping times and freight costs, critical for fast‐fashion turnover.

• Free trade agreements (e.g., USMCA for North America, EU‐Korea FTA for some European lines) further optimize tax and duty rates.

Cultural & Craftsmanship Traditions

• Italy’s denim artisans trace techniques back to Tuscan heritage looms. This cultural cachet translates into a premium pricing strategy for Diesel’s top‐tier lines.

• Turkish factories often run apprenticeship programs in partnership with local universities, ensuring a steady pipeline of skilled workers trained in sustainable dyeing and wash methods.

• Chinese manufacturers continuously upgrade machinery—acquiring Ozone, laser, and ultrasonic machines—and staff undergo certified training to meet global compliance standards, including REACH and Bluesign.

Environmental & Regulatory Considerations

• Italy leads in eco‐denim innovations: “ZeroWater” finishing, closed‐loop systems, and solar‐powered drying tunnels.

• Turkey and China are rapidly adopting wastewater treatment upgrades under EU and Chinese government incentives, respectively—reducing discharge by 60–80% in key industrial zones.

• U.S. factories adhere to strict EPA guidelines for chemical usage and effluent management, vital when marketing “Made in USA” garments to eco‐conscious consumers.

How Does Country of Origin Affect Denim Quality and Sustainability?

Country of origin influences raw material sourcing, water usage practices, labor standards, and environmental compliance—all of which shape the quality, fit consistency, and eco‐footprint of Diesel jeans. Italian facilities excel in premium fabric blends and waterless washes. Turkish factories deliver uniform mid‐range fits with improved effluent controls. Chinese plants offer high‐tech finishes but vary on sustainability enforcement. U.S. runs emphasize strict environmental regulations and small‐batch precision. Knowing origin helps consumers gauge durability, ethical standards, and style authenticity.

Raw Materials & Fabric Innovation

• Italy: Premium spinners in Biella and Prato produce selvedge and specialty blends (e.g., ultrafine cotton‐Lycra mixes) known for superior hand feel and shape retention.

• Turkey: Local cotton blends supplemented with imported long‐staple fibers yield durable, mid‐weight denim at accessible prices.

• China: Massive weaving capacity enables rapid prototyping of new fabric weights—ranging from 8 oz. stretch denim to heavyweight 16 oz. rigid styles—used in experimental Diesel capsule collections.

Water & Energy Management

• Italy’s zero‐water finishing lines recycle 99% of wash water, cutting consumption by up to 90%. Solar thermal systems preheat wash baths, slashing energy use.

• Turkish factories have installed biological treatment plants in key textile districts, achieving an average 70% reduction in chemical oxygen demand (COD) and total suspended solids (TSS).

• China’s majolusters (e.g., Guangdong, Jiangsu) face government mandates to upgrade effluent systems; leading facilities now report 60–80% decreases in water consumption per garment.

Labor & Ethical Standards

• Italy enforces strict worker safety regulations (CE certification for machinery, OHS training) and pays living wages well above national minimums.

• Turkish factories comply with a combination of local labor laws and voluntary programs (e.g., Better Work, Sedex), promoting fair wages and safe conditions.

• China implements national labor laws alongside factory‐level audits from brands like Diesel, though enforcement can vary by region. Diesel’s tiered supplier codes aim to standardize practices across all sites.

Fit, Finish & Performance

• Italy’s luxury washes—featuring enzyme treatments and hand‐brushing—produce nuanced whiskering and authentic fade patterns that evolve with wear.

• Turkish facilities focus on fit reproducibility, employing 3D body scanning and AI‐assisted pattern grading to ensure sizing consistency across batches.

• China’s advanced laser machines create precise abrasion marks and perforations without physical abrasives, reducing material waste by up to 30%.

How Can You Verify Where Your Diesel Jeans Were Made?

To pinpoint the origin of your Diesel jeans, inspect the inside care label—look for “Made in Italy,” “Made in Turkey,” “Made in China,” or “Made in USA.” Check serial numbers and batch codes printed on the care tag. Use Diesel’s official website or authentication apps that leverage QR codes or NFC chips embedded in premium lines. Third‐party services like Entrupy or blockchain‐based ledgers also offer provenance verification for high‐end denim.

Care Labels & Inside Tags

• Location Clues: Most Diesel jeans clearly state the manufacturing country on the back of the care label. Premium Italian‐made pairs often feature a small Italian flag icon next to the text.

• Batch Codes & Serial Numbers: Located on a small white tag inside the pocket or waistband, these alphanumeric codes can be cross‐referenced on Diesel’s customer service portal for production details.

Digital Authentication Tools

• QR Codes & NFC Chips: In recent limited‐edition collections, Diesel has embedded chips or printed QR codes on inside patches. Scanning them with the official Diesel app reveals production site, wash process, and authenticity certificate.

• Blockchain Tracking: A handful of premium runs are piloting blockchain systems (e.g., VeChain) to permanently record each jean’s journey—from cotton bale to retail rack—providing an immutable provenance ledger.

Third‐Party Certification & Audits

• Entrupy & Certilogo: These firms offer on‐the‐spot authenticity checks via smartphone apps. Users submit high‐resolution images of stitching, rivets, and labels; AI algorithms compare them against a database of genuine products.

• Industry Standards: Look for OEKO‐TEX, Bluesign, or GOTS logos on wash care tags, indicating the garment meets strict environmental and chemical safety criteria—often associated with specific production regions (Italy and Turkey lead here).

Retailer Transparency

• Authorized Dealers: Purchasing from Diesel flagship stores, official e‐commerce channels, or vetted boutiques ensures accurate origin labeling and reduces risk of counterfeit.

• Questions to Ask: When shopping online or in‐store, inquire about factory certifications, wash processes used, and minimum order commitments—information that authorized dealers and specialized partners like DiZNEW can provide.

What Role Can Custom Manufacturers Like DiZNEW Play in High-End Denim Production?

Custom manufacturers such as DiZNEW bring 20+ years of denim expertise to the table—handling everything from fabric sourcing and pattern making to advanced washes and small‐batch runs. With a 30‐piece minimum order quantity (MOQ) and the capacity for 10,000+ units, DiZNEW supports both boutique designers and established brands. Their full‐service OEM/ODM model covers plus sizes, selvedge lines, intricate distressing, and private‐label solutions, all under one roof in China.

OEM/ODM Partnerships: From Concept to Closet

• End‐to‐End Services: DiZNEW offers full turnkey solutions—starting with trend research, CAD pattern development, and fabric sampling, through washing, hardware selection, and final quality inspections.

• Flexible MOQ: With a low threshold of 30 pcs per style, even emerging designers can test the market without massive upfront investment. For growing brands, DiZNEW scales up to 10,000+ pieces, ensuring continuity as orders expand.

Specialized Offerings & Fabric Types

• Plus Sizes & Inclusive Cuts: DiZNEW’s pattern library encompasses sizes up to 6XL, with fit sessions and 3D virtual prototyping to guarantee flattering silhouettes across all body types.

• Selvedge & Premium Denim: Partnering with Japanese and Italian mills, DiZNEW sources raw selvage and ring‐spun fabrics, offering authentic high‐cost‐per‐yard options for luxury‐grade jeans.

• Complex Washes & Vintage Effects: In‐house wash kitchens feature laser engraving, ozone fading, enzyme treatments, and hand whiskering. Clients can customize wash recipes to replicate top‐tier fashion editorials or invent signature finishes.

Quality Control & Compliance

• Onsite Inspections: Dedicated QC teams conduct inline checks at each production stage—fabric inspection, cut‐and‐sew accuracy, wash consistency, and final measurements.

• Certifications: DiZNEW’s facilities hold ISO 9001, ISO 14001, and BSCI certifications. They comply with REACH, CPSIA, and other global standards—ensuring your custom line meets regulatory requirements for every market.

Serving U.S. Boutique Buyers & High‐End Labels

• Speed to Market: With optimized logistics channels (air freight, sea freight LCL/FCL), DiZNEW offers shipping solutions that balance cost and lead time—critical for fast‐turn collections.

• Private‐Label Flexibility: Clients receive white‐label packaging options, custom hang tags, woven labels, and private‐brand garment bags—so your jeans arrive on rack exactly as you envisioned.

• Collaborative Approach: DiZNEW functions as an extension of your design team, providing fabric drape samples, wash drafts, and fit call feedback until the final prototype nails your brand DNA.

Understanding where Diesel jeans are manufactured illuminates the intersection of craftsmanship, cost strategy, and sustainability that powers one of the world’s most recognizable denim brands. From Italy’s artisan workshops to Turkey’s efficient wash houses, China’s high‐tech finishing lines, and the U.S.’s limited‐edition ateliers, each location brings unique value to every pair of Diesel jeans. If you’re a designer, boutique owner, or brand manager ready to launch your own high‐end denim line, DiZNEW is your trusted partner.

With over 20 years of experience, comprehensive OEM/ODM services, low MOQs, and the capacity for large orders, DiZNEW tailors every detail—from fabric selection and bespoke fits to complex washes and private‐label packaging. Ready to bring your denim vision to life? Contact DiZNEW today for a personalized quote and start crafting jeans that stand out in quality, style, and authenticity.

Handcrafted crochet patch jeans in vintage wash, ideal for indie labels and boutique fashion creatives.

Custom denim shorts with feather-textured fabric and raw hem. Built for curated fashion retailers & designers.

Custom straight-leg denim in black-grey gradient wash, tailored for curated designer boutiques.

Artfully faded and intricately embossed, these wide-leg jeans blend streetwear aesthetics with vintage-inspired craftsmanship.