What Is Apparel Manufacturing? An Expert Guide for Denim Designers & Boutique Retailers

- Share

- Issue Time

- Aug 9,2025

Summary

Discover the essentials of apparel manufacturing in our expert guide tailored for denim designers and boutique retailers. Elevate your brand today!

Imagine you’ve sketched the perfect pair of high-rise, rigid selvedge jeans or a slouchy baggy silhouette that reflects your brand’s DNA. You know that getting these designs into production isn’t just about finding a tailor or a factory—you need a systematic, end-to-end process that transforms raw materials and concepts into consistent, on-trend garments.

Apparel manufacturing is the backbone of every successful fashion label, big or small, yet its complexity often intimidates indie designers and boutique owners. Understanding what goes on behind the scenes—from patternmaking and fabric sourcing to cutting, sewing, finishing, and quality checks—is crucial for launching on time, within budget, and with the exact look and fit your customers expect.

Apparel manufacturing is the end-to-end process of translating a clothing design concept into a finished garment. It includes stages like design development, patternmaking, fabric sourcing, cutting, sewing, finishing, and quality control. For denim brands, mastering apparel manufacturing ensures consistent fit and quality across batches, optimizes cost and lead times, and helps maintain compliance with safety and environmental standards, while meeting brand specifications and global regulations.

But when you first dive in, it can feel like deciphering an industry code—terms like OEM, ODM, marker making, AQL, and grading rules swirl around without context. You might wonder: “What exactly does an apparel manufacturer do day to day?” or “How do I choose the right partner for my custom denim line?”

To answer these questions, we’ll unpack each stage of apparel manufacturing, compare service models, explore cost drivers, and show you how a specialized denim factory like DiZNEW can turn your sketches into retail-ready pieces with a minimum order of just 30 units. Ready to see behind the curtain? Let’s get started.

What Is Apparel Manufacturing and Why Is It Crucial for Your Denim Brand?

Apparel manufacturing is the coordinated workflow that transforms design concepts, technical specs, and raw materials into finished clothing items. It involves roles such as designers, patternmakers, sourcing managers, machine operators, and quality controllers. For denim brands, robust apparel manufacturing ensures each pair of jeans meets fit, finish, and wash standards across multiple sizes and batches, minimizes costly errors, and accelerates time to market—making it a non-negotiable element for growing labels and boutique retailers.

Apparel manufacturing isn’t just “sewing clothes.” It’s a finely orchestrated chain of specialists, machines, and processes designed to uphold consistency and efficiency. Let’s explore three critical dimensions.

What Does “Apparel Manufacturer” Mean?

An apparel manufacturer is an entity—often a factory or a vertically integrated company—that possesses the machinery, skilled workforce, and supply-chain network to produce garments at scale. They:

• Interpret tech packs and CAD flats to set up production lines

• Source and stock fabrics, trims, and hardware

• Train operators on specialized machines (e.g., flat-bed spreaders, industrial chainstitchers)

• Implement quality protocols at every stage

• Coordinate logistics for inbound raw materials and outbound finished goods

In short, they turn your design blueprint into tangible products.

What Is the Job Description of Apparel Manufacturing?

Within the factory ecosystem, job roles break down into:

• Production Manager: Oversees timelines, capacity planning, and labor allocation.

• Sampling Coordinator: Manages prototype creation, tracks fit-sample approvals, and logs revision requests.

• Fabric & Trim Buyer: Sources denim from cone mills, secures buttons, zippers, and labels, negotiates pricing and lead times.

• Line Supervisor: Monitors sewing lines, solves bottlenecks, enforces safety standards.

• Quality Assurance Inspector: Performs AQL (Acceptable Quality Level) checks on samples and bulk rolls, documents non-conformities.

Understanding these roles helps you communicate clearly and hold each party accountable.

What Is an Example of the Apparel Industry?

Denim manufacturing offers a clear case study. A mid-tier denim brand might:

1.Develop a capsule collection of five jean styles.

2.Work with a factory’s design team to translate mood-board visuals into technical flats.

3.Source 12-ounce, rope-dyed Japanese selvedge and stretch blends from approved mills.

4.Produce fit samples (2–3 iterations per style) to refine rise, hip, and leg opening.

5.Finalize a tech pack with precise specs and grading rules.

6.Place an order for 200 units (MOQ 30 units per style at DiZNEW), schedule a wash run, and ship finished jeans to the U.S. showroom.

Without a clear grasp of apparel manufacturing, each of these steps can derail—leading to delays, inflated costs, or disappointing quality. By demystifying the terminology and workflows, denim designers and boutique retailers can confidently navigate factory partnerships and scale their businesses with control and predictability.

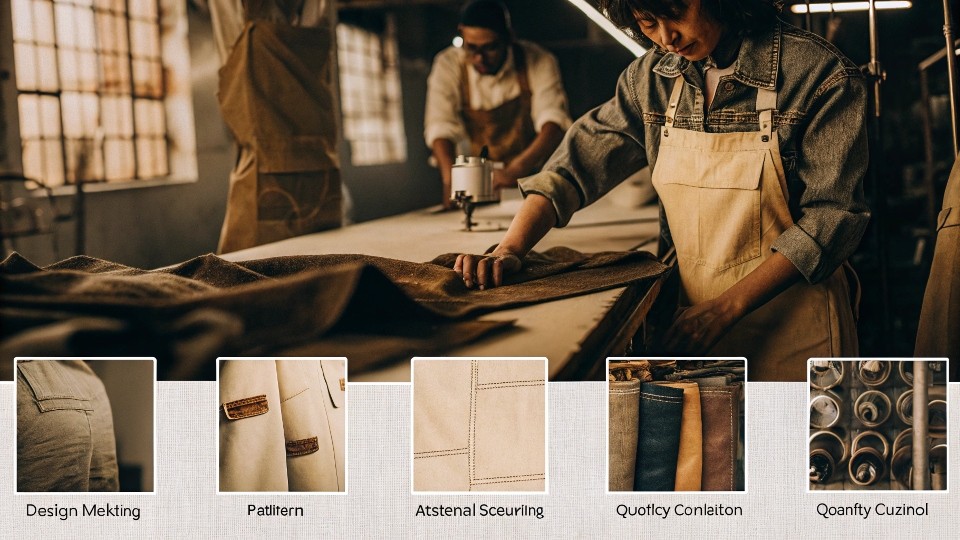

What Are the Essential Stages of the Apparel Manufacturing Process?

The apparel manufacturing process typically follows six key stages: 1) Design & Development, 2) Material Sourcing & Procurement, 3) Patternmaking & Prototype Sampling, 4) Grading & Marker Making, 5) Cutting, Sewing & Assembly, and 6) Finishing, Quality Control & Packaging. Each phase builds on the previous one, ensuring the final garment aligns with design intent, fit specifications, quality standards, and cost targets—critical for delivering consistent, on-brand denim products.

Understanding each stage helps you set realistic timelines and budgets, anticipate potential roadblocks, and collaborate effectively with your manufacturing partner.

Stage 1: Design & Development

• Concept Creation: Mood boards, trend research, and consumer insights inform silhouettes and wash treatments.

• Technical Flats: Clean, line-drawn representations of every view (front, back, side, pocket details).

• Style Sheet: Summarizes style name, colorways, target retail price, and any special treatments (e.g., enzyme wash, resin coatings).

Stage 2: Material Sourcing & Procurement

• Fabric Selection: Denim weight (8–16 oz), fiber content (100% cotton vs. stretch blends), dye method (rope vs. slasher dyed).

• Trim & Hardware: YKK zippers, brass buttons, copper rivets, branded leather patches, woven labels.

• Lead Times & Minimums: Japanese selvedge may require 60–90 days lead, whereas domestic blends can ship in 14–30 days.

Stage 3: Patternmaking & Prototype Sampling

• Block Patterns: Base templates for each size that define fit and ease.

• Sample Cutting & Sewing: First physical sample—often called the “toile” or “fit sample.”

• Fit Review: Stakeholder feedback on rise, thigh ease, knee taper, hem width.

• Revisions: Up to 2–3 rounds to perfect the garment before bulk runs.

Stage 4: Grading & Marker Making

• Grading: Scaling patterns up and down the size range using predefined increments (e.g., +1” waist, +0.5” thigh).

• Marker Making: Nesting patterns onto fabric widths to optimize yardage yield—critical for cost control in denim.

Stage 5: Cutting, Sewing & Assembly

• Fabric Spreading & Cutting: Automated spreaders and cutting machines minimize human error.

• Sewing Lines: Dedicated operations for side seams, inseams, pocket construction, Y-stitching on back pockets.

• Bar-tacking & Reinforcements: High-stress points get extra security with bartacks or rivets.

Stage 6: Finishing, Quality Control & Packaging

• Wash & Distressing: Enzyme wash, stonewash, bleach, laser whiskers, and hand sanding.

• Quality Inspections: AQL sampling on critical dimensions, stitch density, hardware durability, color consistency.

• Packaging: Fold specs, polybag dimensions, hangtag attachments, carton packing—ready for retail or direct-to-consumer shipments.

Every delay or miscommunication at any stage can cascade into higher costs, missed delivery windows, or product recalls. By mapping out these six stages and partnering with a factory experienced in denim—like DiZNEW—you ensure your custom jeans, jackets, or shorts come out exactly as envisioned, on time, and within budget.

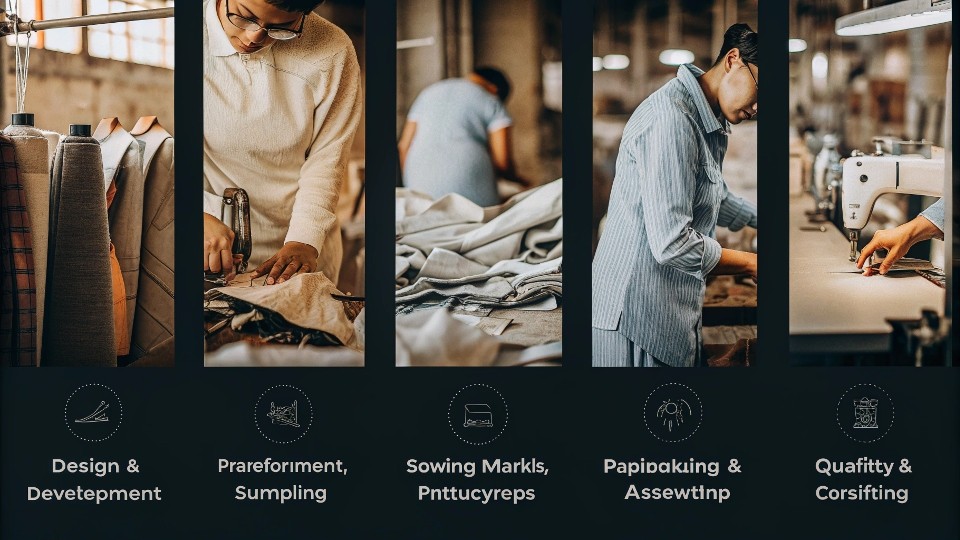

How Do OEM and ODM Services Differ in Apparel Manufacturing?

OEM (Original Equipment Manufacturer) services produce garments strictly based on your designs and tech packs, allowing you full creative control. ODM (Original Design Manufacturer) services offer end-to-end solutions—design, development, sampling, and production—using the factory’s in-house expertise and existing patterns. Choosing OEM preserves your unique brand identity, while ODM accelerates time to market and can reduce upfront costs by leveraging the manufacturer’s design resources.

Choosing between OEM and ODM depends on your brand’s needs, resources, and long-term vision.

OEM Explained: Custom Production Under Your Brand

• Asset Ownership: You own all designs, tech packs, patterns, and IP.

• Creative Freedom: Total flexibility to specify fabrics, hardware, construction methods, and washes.

• Higher Initial Investment: You cover pattern development, tech-pack creation, and sample costs, but you retain full rights.

ODM Explained: End-to-End Design & Manufacturing

• Turnkey Solution: The factory provides design proposals, pattern blocks, fabric recommendations, and ready-to-go samples.

• Speed to Market: Reduced lead times since patterns and processes are pre-validated.

• Shared Creativity: You overlay your brand style on existing silhouettes—ideal for brands needing rapid diversification or seasonal collections.

Pros & Cons Comparison

| Aspect | OEM | ODM |

| Investment | Higher upfront (patterns, tech packs) | Lower upfront (pre-existing assets) |

Control | Full design/IP ownership | Limited to available templates |

| Lead Time | Longer (pattern & sample development) | Faster (pre-validated designs) |

| MOQ | Factory MOQ applies per style | Often similar MOQs, sometimes lower |

Choosing Between OEM and ODM for Your Denim Product

• Brand Identity Matters: If your unique pocket stitch or bespoke hardware is your USP, OEM is the route.

• Time & Budget Constraints: ODM can fast-track seasonal drops or test new silhouettes without heavy R&D.

• Long-Term Strategy: Many brands start with ODM to establish a line, then transition to OEM as they scale and protect IP.

At DiZNEW, we offer both OEM and ODM pathways. Our OEM clients benefit from 20+ years of in-house denim R&D, while ODM clients tap into a library of proven styles—plus the ability to tweak fit, fabrics, and finishes. This flexibility empowers designers and boutique retailers to choose the model that best aligns with their creative and commercial goals.

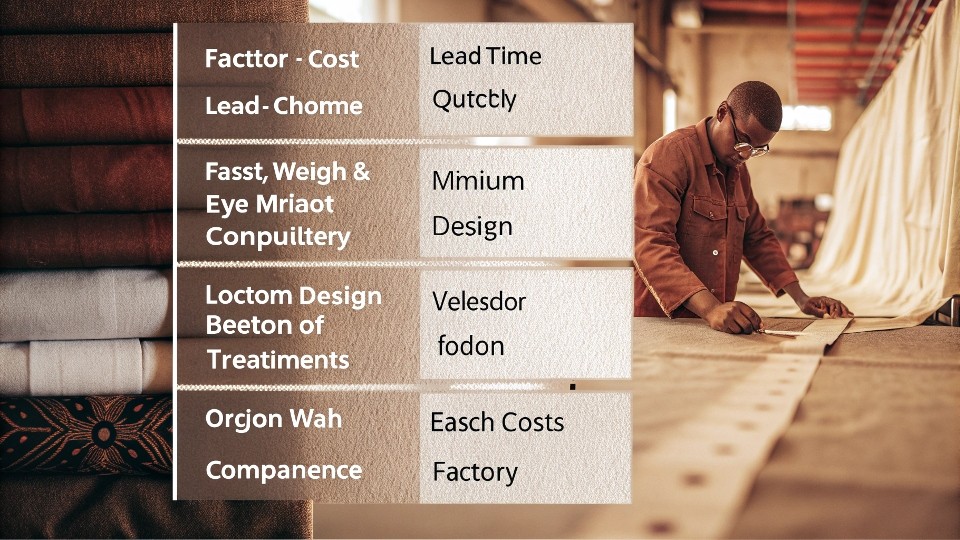

What Factors Affect Apparel Manufacturing Cost, Lead Time, and MOQs?

Key factors influencing cost, lead time, and minimum order quantities (MOQs) include fabric choice (weight, origin, dye method), complexity of design (number of pieces, special trims, wash treatments), order volume, factory location, and compliance requirements. Heavier selvedge denim with custom hardware pushes costs and lead times higher, while simpler stretch blends and existing silhouettes can lower both. Understanding these drivers helps you negotiate pricing, optimize your collection mix, and plan production schedules effectively.

Let’s unpack each factor and see how it shapes your project’s bottom line and timeline.

Fabric & Trim Selection

Denim Weight & Composition:

– Lightweight 8–10 oz (summer styles) vs. mid-weight 12–14 oz vs. heavyweight 16+ oz (premium feel).

– 100% cotton rope-dyed selvedge commands a 20–30% price premium over domestic slasher-dyed blends.

• Specialty Hardware: Custom engraved buttons, embossed leather patches, laser-etched rivets add setup fees and longer lead times.

Complexity of Design & Construction

• Pattern Pieces: More panels (e.g., articulated knees, gussets) increase cutting and sewing labor by 10–25%.

• Wash & Finishing Techniques: Stonewash, bleach, and laser distressing require separate wash queues; each effect adds 1–2 weeks.

• Embellishments: Embroidery, patches, and hand-applied finishes incur manual labor costs and QC steps.

Order Quantity & Production Scale

MOQ Impact:

– Standard factory MOQ: 30–50 units per style (DiZNEW’s minimum).

– Larger orders benefit from tiered pricing—5% discount at 100 pcs, 10% at 300 pcs, etc.

• Economies of Scale: Bigger runs dilute setup costs (pattern blocks, marker making) across more units, lowering per-unit price.

Factory Location & Logistics

• Domestic vs. Overseas: U.S. domestic runs cut shipping time but cost 20–40% more in labor.

• Transit Times: Sea freight adds 30–45 days, air freight cuts it to 5–7 days at 3–5× the cost.

• Tariffs & Duties: Know your Harmonized System codes to anticipate import fees—critical for U.S. buyers.

Quality Standards & Compliance Requirements

• CSR & Sustainability: Organic cotton, OEKO-TEX®, or bluesign® certifications add audit fees and material premiums (5–15%).

• Lab Testing: Colorfastness, shrinkage, and heavy-metal tests typically cost $50–$150 per style.

• On-Site Inspections: AQL third-party checks (e.g., SGS, Bureau Veritas) run $25–$50 per inspection.

Table: Cost & Lead Time Impact by Factor

| Factor | Cost Impact | Lead Time Impact |

12 oz Japanese selvedge | +25–30%/unit | +30–45 days |

| Custom hardware setup | +$0.50–$1.50 | +10–15 days |

| Stonewash & distressing | +$2–$5/sample | +7–10 days |

MOQ under 50 pcs | +10–15%/unit | Standard |

| CSR certification audit | +$1–$3/unit | +7–14 days |

Knowing how each element affects your project empowers you to balance creative ambition with commercial reality. At DiZNEW, we guide you through these trade-offs, providing transparent quotes and timeline estimates so you can plan collections that hit price points and delivery windows without surprises.

How Can You Partner with a Specialized Denim Manufacturer like DiZNEW?

Partnering with DiZNEW means tapping into 20+ years of denim R&D and manufacturing expertise, flexible MOQs (30 pieces per style), and full OEM/ODM services—from tech-pack development and patternmaking to wash house, quality control, and global logistics. We serve U.S. indie brands and high-end labels, delivering custom plus-size jeans, baggy, skinny, selvedge, and more with your logo and packaging—end-to-end solutions designed to bring your denim vision to life.

Here’s how you can leverage DiZNEW’s capabilities to streamline your denim supply chain and elevate your brand.

DiZNEW’s 20+ Years of R&D & Manufacturing Expertise

In-House Lab: Proprietary wash recipes, enzyme tests, and laser machines deliver consistent finishes.

• Global Sourcing: Direct relationships with Japanese, Turkish, and U.S. denim mills ensure you access the best fabrics—rope-dyed selvedge, stretch blends, and organic options.

• Technical Team: Patternmakers, fit engineers, and tech-pack specialists collaborate in Dongguan’s design studio to refine your ideas.

Steps to Begin Your Custom Denim Project

1.Inquiry & Consultation: Share sketches, inspiration boards, or raw tech packs.

2.Proposal & Quote: Receive a detailed breakdown of costs, timelines, and MOQs within 3–5 business days.

3.Tech-Pack Development: Collaborate on technical flats, spec sheets, and grading rules.

4.Sampling & Fit Approval: Turn samples around in 10–15 days, with up to three revision cycles.

5.Production & Quality Control: Bulk runs begin with AQL inspections and wash-house sign-off.

6.Packaging & Logistics: Custom hang tags, polybags, cartons, and DDP/DDU shipping options.

Plus-Size, Baggy, Skinny & Specialty Jeans: Our Custom Capabilities

• Plus Sizes 1X–5X: Grading blocks designed for proportional ease and comfort.

• Baggy & Stacked Jeans: Additional pattern engineering for drop crotch and elongated hem allowances.

• Selvedge & Rigid Denim: Vintage chain-stitch finishes, selvage ID accents, and authentic hardware.

• Jogger Jeans & Shorts: Elasticized cuffs, drawcords, and tailored silhouettes.

Minimum Order Quantities, Sampling & Production Timelines

• MOQ: 30 pcs per style, per colorway—ideal for indie brands testing markets.

• Sample Lead Time: 10–15 days for first proto; revisions in 5–7 days each.

• Bulk Production: 30–45 days depending on wash complexity and order size.

Ensuring On-Time Delivery and Brand-Consistent Quality

• Regular Milestones: Weekly updates on material arrival, cutting completion, and wash progress.

• Photographic Reports: High-res images of in-process garments for remote approvals.

• Final AQL Inspection: Third-party QC before packing, confirming all units meet your spec tolerances.

Working with DiZNEW gives you a strategic partner, not just a contract manufacturer. We co-innovate, offering design input, fabric R&D, and finishing expertise that bring your denim vision to life with precision and consistency.

Conclusion: Ready to Elevate Your Denim Line?

Navigating apparel manufacturing can feel like exploring uncharted territory—full of technical jargon, hidden costs, and tight timelines. But with a clear roadmap of the six essential stages, an understanding of OEM vs. ODM, and insight into cost drivers, you’re equipped to make informed decisions that protect your brand identity and bottom line. Partnering with a specialized denim factory like DiZNEW, with over two decades of R&D, low MOQs, and turnkey services, transforms complexity into confidence.

Whether you’re an emerging designer launching your first capsule or a boutique retailer expanding into private-label denim, DiZNEW is here to help every step of the way. From developing pixel-perfect tech packs to delivering wash-tested, fit-approved jeans, our goal is simple: bring your creative vision to life precisely, on time, and within budget.

Get started today—contact DiZNEW for a detailed quote on custom tech-pack development, prototype sampling, and full-scale production. Let’s create denim that tells your brand’s story and stands out on the racks. Your next best-selling jeans are just one inquiry away.

Classic straight jeans with bold contrast stitching in light blue, dark blue, and black — made for standout collections.

Washed high-rise wide-leg jeans with clean lines and vintage tint — ideal for refined luxury denim collections.

Statement cargo jeans with stacked fit, bleach fade, and heavy-duty pockets — perfect for streetwear labels.

Eye-catching patchwork stacked jeans with contrast panels and utility pockets — bold choice for designer streetwear.