What Are the Key Advantages of Denim? A Deep Dive into Its Durability, Versatility, and Style

- Share

- Issue Time

- Sep 9,2025

Summary

Discover the numerous advantages of denim, from its durability and versatility to its timeless style. Explore why denim remains a wardrobe staple for all.

What Are the Key Advantages of Denim? A Deep Dive into Its Durability, Versatility, and Style

Denim has been a wardrobe staple for generations, yet its popularity shows no signs of waning. From rugged workwear in the 19th century to runway-ready fashion today, denim’s enduring appeal begs the question: what makes this humble cotton twill so indispensable?

Maybe it’s its unique blend of toughness and comfort. Maybe it’s the way it evolves—fading gracefully over time, becoming a kind of personal canvas. Or perhaps it’s the infinite range of styles — from skinny jeans to baggy, from jackets to shorts — that allows everyone to find their perfect denim match.

Denim’s strengths lie in its unmatched durability, effortless comfort, and remarkable versatility. It excels in everyday wear thanks to high-quality weaves like selvage and stretch blends. Styling options span every fashion niche, and eco‐friendly innovations are making production greener. Custom OEM/ODM services empower brands to create unique pieces in small or large batches, with MOQs as low as 30 pieces.

Picture this: you’re flipping through your favorite boutique’s Instagram, and a pair of custom wash jeans catches your eye. That exact pair was designed in someone’s sketchbook and then produced in a factory like DiZNEW, which has over two decades of denim expertise. From that spark of inspiration to the first runway debut, the journey of denim is a story of craftsmanship, innovation, and pure grit. Ready to unravel the secrets behind denim’s power? Let’s dive in.

What makes denim one of the most durable fabrics?

Denim’s rugged twill weave and high-tensile cotton fibers create exceptional tear resistance and shape retention, even after years of wear. Premium selvage denim, woven on vintage shuttle looms, offers tighter construction and cleaner edges, prolonging the life of your jeans. Quality finishing processes—like enzyme washes and reinforced stitching—also contribute to denim’s legendary longevity, making it a sustainable, cost‐effective wardrobe investment.

Denim’s story of durability begins with the fundamental structure of the fabric: a 3×1 twill weave. Unlike plain weaves, denim features diagonal ribbing that distributes stress across multiple threads. This design slows down the rate of abrasion and reduces the chance of catastrophic tears. But not all denim is created equal. Here’s what separates standard denim from industrial-strength jeans:

Cotton Quality and Yarn Count

– Low yarn count (e.g., 6–10 ounces per square yard) yields lighter, softer denim, but lower tensile strength.

– Mid-weight (10–14 oz) is the sweet spot for daily wear, balancing durability with comfort.

– Heavyweight (14–21+ oz) is nearly indestructible, ideal for motorcycle riders and outdoor labor.

Shuttle Looms vs. Projectile Looms

Shuttle looms produce selvage denim, characterized by tightly bound edges that prevent unraveling. In contrast, projectile looms run faster but produce denim with looser edges. Selvage denim often commands a premium—reflecting heritage, slower production, and superior durability.

Finishing Techniques

– Enzyme washes: Use cellulase enzymes to remove surface fuzz, softening the fabric without compromising strength.

– Resin treatments: Impart shape retention, so jeans keep their cut even after repeated washes.

– Reinforced stitching: Triple-needle or safety-stitched seams reduce stress at pockets and crotches.

Real-World Data

| Denim Type | Tear Strength (N) | Abrasion Cycles to Hole |

| Standard 12 oz | 30 | 15,000 |

| Selvage 14 oz | 45 | 25000 |

| Stretch Blend 12 oz | 35 | 18000 |

In practice, a pair of high-quality selvage jeans from a factory like DiZNEW can last 5–10 years of regular wear, with proper care. This translates to fewer replacements, lower environmental impact, and a better investment for consumers.

Critically speaking, some argue that the denim boom has prioritized novelty washes and fashion over function. Distressed details, holes, and acid washes look great but compromise the fabric’s structural integrity. Savvy buyers should balance style trends with the core strengths of denim to ensure longevity.

How does denim achieve both structure and comfort?

Denim comfort hinges on the interplay of fabric weight, yarn twist, and elastic fibers. Stretch denims incorporate 1–3% spandex or elastane, allowing jeans to move with your body without sagging. Custom deep-engineering—measuring waist, hip, thigh, and leg opening—ensures a tailored fit for every silhouette. Plus-size ranges and advanced pattern making guarantee consistent comfort and confidence across all body types.

For decades, denim was synonymous with stiff, rigid jeans. Today’s consumers demand a softer hand feel, enhanced mobility, and a personalized fit. Here’s how modern manufacturing addresses these needs:

Fabric Engineering

Denim mills now produce specialized weaves:

– Comfort Stretch: 98% cotton, 2% elastane. Ideal for skinny and straight cuts.

– Super Stretch: 95% cotton, 5% elastane. Perfect for active or form-fitting silhouettes.

– Rigid Denim: 100% cotton, retains shape for break-in appeal but requires an initial stiff feel.

Garment Construction

– Serged seams: Thread wraps around raw edges to prevent fraying.

– Curved waistband: Conforms to the back, eliminating gaping at the waist.

– Gussets and articulated knees: Increase mobility for baggy and jogger styles.

Size Inclusivity

Modern clothing brands face criticism for limited plus-size options. DiZNEW addresses this by offering plus-size jeans starting at the same MOQ (30 pieces) as standard sizes, with expanded grading charts:

Waist (in) 28-48

Hip (in) 36-56

The Human Angle

Imagine Amanda, a boutique owner in San Francisco. Her clients range from petite creatives to curvy professionals. By partnering with DiZNEW’s OEM/ODM services, she orders a mix of stretch straight-jeans and high-rise plus-size jeans. Her customers appreciate the second-skin feel and perfect fit, leading to a 30% boost in repeat purchases.

Critically, some denim lovers argue that adding elastane dilutes the “authentic” denim experience. They swear by 100% cotton pairs that mold uniquely to the wearer’s body. There’s merit in both camps: pure denim for long-term patina and stretch blends for immediate comfort and convenience.

How can denim transition seamlessly from casual to smart–casual?

Denim’s adaptability lies in its wide array of cuts, finishes, and colors. A dark indigo straight-leg jean with minimal distress pairs effortlessly with a blazer for smart–casual events. Baggy or tapered jogger denims cater to streetwear aficionados. For warmer days, denim shorts or lightweight chambray shirts provide breathable style. Plus, seasonal washes—from raw to stone-washed—ensure denim works in any weather and occasion.

Denim’s ability to morph between style codes is unmatched. Let’s explore how diverse designs, washes, and layering techniques create looks for every setting:

Cuts and Silhouettes

– Skinny: Tight from hip to ankle, ideal for slender frames and layering under boots.

– Straight: Uniform width, classic and office-appropriate when paired with loafers or a crisp shirt.

– Baggy: Roomy, perfect for streetwear pairs and urban cultures.

– Jogger: Elasticized ankle cuffs and drawstring waists blend casual comfort with a tailored look.

– Straight-Leg Shorts & Skirts: Transition effortlessly from beach days to brunch.

Washes and Treatments

Denim wash plays a critical role in style:

– Raw/Unwashed: Deep indigo that ages distinctly with wear.

– Stone Wash: Softer hand feel, casual vintage vibe.

– Acid Wash: Bold, high‐contrast patterns popular in edgy streetwear.

– Bleach & Dip Dye: Contemporary fashion statements for avant‐garde collections.

Seasonal Adaptability

What weather is denim good for?

Denim’s mid-weight options (10–12 oz) are perfect for spring and fall. Heavyweights (14+ oz) offer wind resistance in winter. Lightweight chambray (4–6 oz) serves as breathable summer shirts and shorts. Layering a denim jacket over a cotton tee or hoodie provides insulated style without bulk.

Designer vs. Boutique Perspectives

High‐end designers may invest in premium selvedge denim and artisanal hand distressing for runway exclusivity, while online boutiques focus on fast-turnaround custom washes and limited‐edition drops. DiZNEW’s flexible manufacturing allows both to co-exist: small runs (MOQ 30) for exclusive capsule collections, and large runs (10,000+) for mass-market appeal.

From a critical viewpoint, denim’s saturation in the market sometimes leads to “denim fatigue.” Consumers are overwhelmed by endless drops, gimmicky finishes, and fleeting trends. Savvy buyers and brands should partner with knowledgeable manufacturers, such as DiZNEW, to strike a balance between innovation and authenticity.

How is modern denim manufacturing reducing water and chemical use?

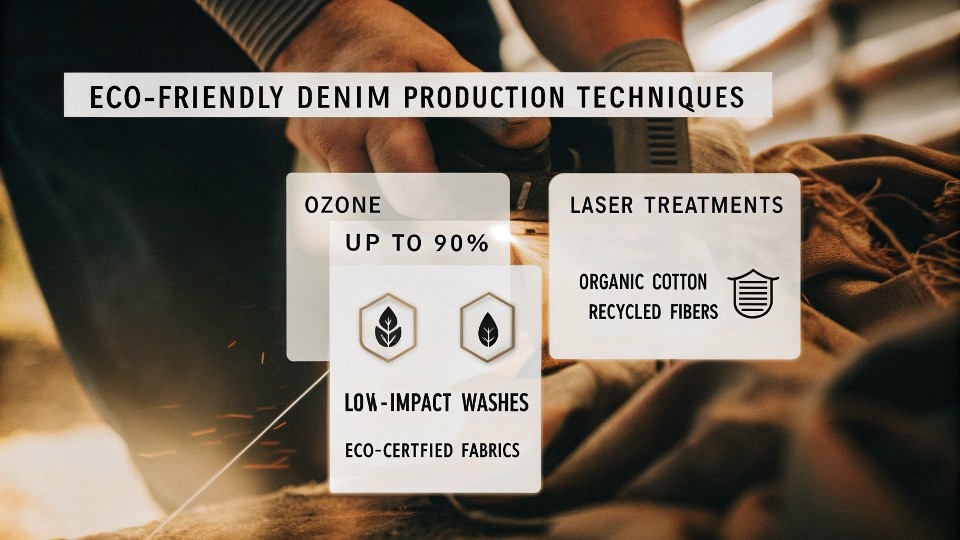

Eco-friendly denim production hinges on water-saving finishing processes like ozone and laser treatments, which cut water use by up to 90%. Organic cotton and recycled fibers reduce chemical inputs and landfill waste. DiZNEW’s OEM/ODM offerings include low-impact washes and eco‐certified fabrics, enabling brands to meet ethical standards without sacrificing style or performance.

Denim’s historical water footprint is enormous: a single pair of jeans can consume 7,000–10,000 liters of water from cotton cultivation to finished garment. Today’s consumers demand greener practices. Here’s how the industry is stepping up:

Innovative Washing Technologies

– Ozone Washing: Uses ozone gas to achieve stone-washed looks with 50–70% less water and zero pumice stones.

– Laser Fading: Precision lasers create fade patterns without chemicals or water.

– Enzyme Treatment: Replaces harsh bleaching agents, breaking down indigo dyes biologically.

Sustainable Fibers

– Organic Cotton: Grown without toxic pesticides, using 40% less water than conventional cotton.

– Recycled Polyester: Blended in denim for stretch, diverts plastic bottles from landfills.

– TENCEL™ Lyocell: Adds softness and moisture management, produced in closed-loop systems.

Certifications and Standards

Factory audits and certifications—GOTS, OEKO-TEX, Bluesign—verify eco‐performance. DiZNEW partners with certified mills and adheres to strict wastewater treatment protocols, ensuring compliance with global environmental regulations.

The Economics of Green Denim

| Process | Traditional Water Use | Eco-friendly Process Water Use |

| Conventional Wash | 20 L per kg denim | |

| Ozone Wash | 4 L per kg (+ energy) | |

| Laser Treatment | 1 L equivalent (electric) |

While upfront costs for eco‐technologies can be 10–20% higher, brands often achieve a 15–30% premium in retail pricing by marketing sustainable credentials. Over time, reduced water and chemical bills can offset initial investments.

Critically, greenwashing remains a problem in fashion. Brands may tout “eco” denims without full transparency. To avoid misleading claims, partner with factories like DiZNEW that provide detailed audit reports and traceable supply chains.

Why is OEM/ODM service critical for emerging denim brands?

OEM/ODM services allow brands to develop unique denim designs, from custom weaves to bespoke washes and branded hardware. DiZNEW’s low MOQ of 30 pieces empowers startups to sample styles without large upfront costs, while production capacity up to 10,000+ pieces supports growth. Personalized fits, label options, and packaging elevate brand identity and consumer loyalty.

In today’s crowded fashion landscape, differentiation is vital. OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) partnerships give brands the opportunity to stand out:

Product Development Workflow

Concept & Sketch: Brands share mood boards or technical drawings.

Fabric Sourcing: Choose from 50+ denim qualities—raw, selvedge, stretch, organic.

Prototype & Sampling: First samples delivered within 10–14 days, using digital pattern making.

Wash & Finish Trials: Test multiple wash recipes—enzyme, laser, hand-sanding.

Production Planning: Final MOQ 30–10,000+ based on style complexity and fabric availability.

Branding Elements

– Custom Labels & Hangtags: Woven leather patches, custom metal rivets, branded hangtags.

– Private-Label Packaging: Eco-friendly boxes, tissue paper, and stickers.

– Unique Details: Contrast stitching, rivet shapes, zipper pulls engraved with logos.

Quality Control & Compliance

DiZNEW employs strict in-line inspections (AQL 2.5) and final audits. All fabrics meet CE and REACH standards, ensuring consumer safety. Full traceability from farm to finished garment reduces risk and enhances brand reputation.

Scaling with Confidence

Let’s say your online shop in New York sells out its first 200 pairs of slim-fit jeans in days. You can quickly reorder 500–1,000 pairs, tweaking washes based on customer feedback. As demand increases, DiZNEW scales up to 10,000+ units, maintaining consistent quality and delivery times.

Critically, some brands fear loss of control when outsourcing. However, transparent communication, detailed tech packs, and factory visits bridge the gap. With DiZNEW’s decades of expertise, clients enjoy full creative ownership and reliable manufacturing execution.

Conclusion and Call to Action

From its robust twill weave and vintage shuttle-loom heritage to modern stretch blends and eco‐friendly washes, denim’s advantages are as varied as its styles. It remains one of the most durable, comfortable, and versatile fabrics ever invented. But in a saturated market, true differentiation comes from customization, ethical production, and a deep understanding of consumer needs.

Ready to craft your next denim collection? DiZNEW has served American SMEs and high‐end brands for over 20 years, delivering custom plus‐size jeans, baggy fits, selvedge masterpieces, and everything in between. With MOQs starting at just 30 pieces, full OEM/ODM support, and large‐scale capacity up to 10,000 units, your vision can become reality—without compromise.

Contact DiZNEW today for a free consultation and sample pack. Let us help you design, manufacture, and elevate your brand with the perfect denim solution. Your next bestseller is just one inquiry away.