USA-Made Jeans 2025: Ethical Brands & Premium Factories

- Share

- Issue Time

- Apr 1,2024

Summary

Discover top US-made jeans brands! Ethically crafted, durable & eco-friendly. Support local manufacturers with fast shipping & custom designs. Shop now!

What Jeans Are Made in the USA?

In today’s denim market, USA-made jeans have become synonymous with impeccable craftsmanship, innovative design, and a commitment to sustainability.

Featured Snippet:

USA-made jeans are celebrated for their superior quality and ethical manufacturing practices—they blend time-honored American craftsmanship with cutting-edge technology, resulting in denim that’s durable, stylish, and eco-friendly. Picture slipping into jeans that not only elevate your look, but also tell a story of American innovation and environmental responsibility.

Imagine stepping out in a pair of jeans that carry the legacy of generations, while embracing modern technology and sustainable practices. As you read on, you'll uncover the secrets behind the magic of American denim—from the heritage and process that shape every pair to the brands leading the charge in quality and sustainability. Let’s dive into the world of USA-made jeans and see how they can transform your wardrobe.

1. What Makes USA-Made Jeans Unique?

Featured Snippet:

USA-made jeans excel in quality, authenticity, and innovation, combining traditional craftsmanship with advanced technology to produce denim that is durable, stylish, and sustainable.

Dive Deeper: Exploring the Uniqueness of USA-Made Jeans

When it comes to jeans, the “Made in USA” tag is a hallmark of excellence. Here’s why American denim stands out:

A. Heritage and Craftsmanship

Rich Tradition:

American denim has a storied history that blends artisanal techniques with a commitment to durability. For decades, generations of denim makers have perfected the art of crafting jeans that not only look great but also stand up to daily wear and tear.

Hand-Finished Details:

In many USA factories, every pair of jeans gets a personal touch. Skilled artisans add hand-finished details that set each pair apart—embracing slight imperfections that contribute to the character, while ensuring quality through precision stitching and rivet placement.

B. Technological Advancements

Modern Machinery and Tools:

Advanced production equipment, such as computerized cutting systems and laser-guided stitching, ensures uniformity and reduces waste. This modern approach means every pair of jeans is produced with exacting precision.

Data-Driven Quality Control:

Digital quality control systems track every stage of production. For instance, using statistical process control (SPC) methods allows manufacturers to catch and correct issues before the product reaches you.

C. Sustainable Practices

Eco-Friendly Materials:

American denim factories prioritize premium materials like organic cotton and recycled fibers. This focus not only improves the quality of the jeans but also reduces reliance on harmful pesticides.

Reduced Water Usage and Pollution:

Many facilities now implement water recycling and low-impact dyeing techniques. For example, recent innovations have enabled some plants to achieve up to 40% reduction in water usage compared to traditional denim processing methods.

Sustainability Metrics Snapshot:

| Aspect | Traditional Process | USA Sustainable Process | Improvement |

| Water Consumption | 100% | 60% | 40% less |

| Energy Consumption | 100% | 70% | 30% less |

| Chemical Usage | High | Reduced | Significant |

D. Authenticity and Versatility

Genuine American Appeal:

Whether it’s for work, casual outings, or special events, USA-made jeans reflect the ethos of American style. They offer rugged durability for outdoor adventures and a refined look for social events.

Customization Capabilities:

Thanks to flexible OEM/ODM models, manufacturers provide personalized denim designs—tailoring fits, finishes, and styles to meet niche demands. This customization ensures you get a pair of jeans that truly reflects your personality and needs.

2. Which Brands and Manufacturers Lead the USA Denim Market?

Featured Snippet:

Leaders like Blue Delta Jeans, Raleigh Denim, and All American Clothing Co. define excellence in USA denim by combining rich heritage, innovative production techniques, and a commitment to sustainability.

Dive Deeper: Spotlight on American Denim Leaders

The USA denim market is brimming with established brands and new entrants, each contributing uniquely to the industry’s dynamic landscape. Let’s break down the key players:

A. Iconic Denim Brands

Blue Delta Jeans:

This brand has carved a niche with its innovative designs and robust production quality. Embracing both classic and modern silhouettes, Blue Delta Jeans seamlessly blend heritage with contemporary style.

Raleigh Denim:

With a strong focus on durability and functionality, Raleigh Denim builds jeans ideal for demanding lifestyles. Their designs are rooted in the tradition of American workwear, ensuring longevity and performance.

All American Clothing Co:

Emblematic of the true American spirit, this brand champions authenticity. Their jeans cater to a wide range of consumers—from those seeking robust, work-ready denim to fashion-savvy individuals looking for a refined edge.

B. The Spectrum of American Clothing Brands

Beyond the Big Names:

Many independent brands add variety and innovation to the market. These smaller companies often experiment with unique cuts, finishes, and fits, pushing the boundaries of what American denim can be.

Target Segments:

Men’s Denim:

Premium segments like men's jeans made in USA and men's blue jeans made in USA are renowned for their durability and classic appeal.

Women’s Denim:

There’s a growing interest in what women's jeans are made in the USA, with brands focusing on fit, comfort, and style tailored to female consumers.

Market Data Table:

| Category | Market Share (%) | Consumer Satisfaction (Score out of 10) |

| Premium American Jeans | 45 | 9 |

| Mid-Range American Jeans | 35 | 8 |

| International Brands | 25 | 7 |

This table highlights the strong consumer preference for USA-made denim, which continues to dominate due to its blend of quality, ethical production, and design innovation.

C. OEM/ODM Impact on Brand Diversity

Customization as a Game-Changer:

The OEM/ODM model allows brands to tailor products from concept to creation, meeting specific market needs. This flexibility is vital for small businesses to test new ideas without committing to large minimum orders.

Building Long-Term Partnerships:

Manufacturers who offer OEM/ODM services often develop lasting partnerships with retailers and designers, contributing to the longevity and reliability of the American denim brand ecosystem.

3. How Are USA-Made Jeans Produced?

Featured Snippet:

USA-made jeans are crafted through a meticulously controlled process that merges traditional techniques with state-of-the-art technology, ensuring each pair is durable, stylish, and produced with an eye for sustainability.

Dive Deeper: The Production Process of American Denim

Let’s walk through the journey from raw fabric to your finished pair of jeans:

A. Design and Development

Collaborative Design Process:

Designers and production specialists collaborate early in the process using advanced computer-aided design (CAD) software. This integration ensures that creative visions are not only preserved but also optimized for mass production.

Prototyping and Sampling:

Rapid prototyping helps fine-tun every design detail. Iterative feedback allows adjustments before full-scale production begins, ensuring the final product meets the high standards of American denim.

B. Cutting and Stitching Precision

Automated Cutting:

Modern, computerized cutting systems ensure minimal fabric waste and accurate pattern replication. This precision is crucial, especially when producing jeans in bulk.

Advanced Stitching Techniques:

High-speed industrial sewing machines, equipped with digital controls, manage tasks like chain stitching and barrack reinforcements. These machines guarantee that every seam can withstand daily stress while maintaining an impeccable look.

C. Washing and Finishing

Innovative Washing Methods:

Techniques such as laser etching, ozone washing, and controlled enzyme treatments lend each pair its distinct texture and color. These methods are less abrasive on the fabric and environmentally friendly.

Detailing and Finishing Touches:

After washing, jeans undergo finishing, where distressed effects, fades, and accessory attachments are applied. Skilled technicians ensure that each finishing detail adheres to high-quality benchmarks.

D. Quality Control and Inspection

Multi-Stage Testing:

Quality checks occur at every stage—from initial fabric inspection to final product review. Tests for color fastness, durability, and stress resistance ensure only the best jeans reach consumers.

Data-Driven Continuous Improvement:

Manufacturers analyze defect rates and feedback using SPC charts. This data-driven approach helps refine processes and reduce the incidence of production errors.

E. Sustainability in Production

Green Manufacturing Techniques:

Modern American factories incorporate green technologies, such as solar power, energy-efficient machinery, and closed-loop water systems. For example, some plants have recorded a 30% reduction in energy consumption compared to older lines.

Comparative Table:

| Metric | Traditional Process | USA Sustainable Process | Improvement |

| Water Usage | 100% | 60% | 40% less usage |

| Energy Consumption | 100% | 70% | 30% reduction |

| Chemical Waste | High | Low | Significant decrease |

This detailed process ensures that every pair of USA-made jeans meets high aesthetic standards, but also adheres to principles of environmental conservation.

4. Do USA-Made Jeans Uphold Sustainable and Ethical Standards?

Featured Snippet:

Absolutely—USA-made jeans are produced under strict sustainable and ethical standards, leveraging eco-friendly materials and production processes that significantly reduce environmental impact while upholding fair labor practices.

Dive Deeper: Sustainability and Ethics in American Denim

Let’s examine how sustainability is woven into the fabric of American denim production:

A. Environmental Initiatives

Green Production Techniques:

Many American denim factories use energy-efficient machinery and water recycling systems, drastically cutting resource use. For instance, the closed-loop water systems employed in several facilities ensure that up to 40% less water is used per production cycle.

Eco-Friendly Material Choices:

Organic cotton and recycled fibers are increasingly popular in American denim, reducing reliance on chemicals and pesticides. This commitment not only improves the durability of the jeans but also minimizes the carbon footprint of production.

B. Ethical Manufacturing Practices

Fair Labor Practices:

Strict adherence to labor laws and regular audits ensure that workers are treated fairly and work in safe conditions. This ethical dimension is a key reason why consumers trust USA-made jeans.

Community Investment:

Many manufacturers support local communities by offering training programs, job opportunities, and investments back into the local economy. This support creates a positive cycle where community welfare fuels better work practices and product quality.

C. Certifications and Standards

Industry Certifications:

Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® add credibility, assuring consumers that the jeans have been produced with minimal environmental harm and ethical labor practices.

Case in Point:

One prominent manufacturer recently achieved a 98% quality score on a sustainability index—an achievement that underscores the rigorous environmental standards followed throughout production.

D. Consumer Transparency

Accessible Production Data:

With improved labeling and digital tracking technologies, consumers can now trace every step of a pair of jeans—from the cotton field to the finished product. This level of detail builds trust, knowing that ethical practices are not just claimed, but verified.

Review and Rating Insights:

Independent consumer surveys consistently rate USA-made jeans higher in sustainability and ethical production compared to many imported alternatives.

5. Are USA-Made Jeans Worth the Investment?

Featured Snippet:

Yes, USA-made jeans are worth the investment for their unmatched durability, superior craftsmanship, and the added value of sustainable, ethical production practices. They offer longevity and style that outperforms many imported alternatives.

Dive Deeper: Evaluating the Investment Value of American Denim

Let’s look at why spending a bit more on USA-made jeans often pays off in the long run:

A. Cost Versus Quality

Durability for the Long Haul:

While the upfront cost of USA-made jeans might be higher, their longevity makes them cost-effective. Many users report that these jeans require fewer repairs and replacements, meaning you save money over time.

Comparative Analysis:

| Feature | USA-Made Jeans | Imported Jeans |

| Average Lifespan (Years) | 5–7 | 3–5 |

| Annual Repair Frequency | 0.5 | 1.2 |

| Average Customer Rating | 9/10 | 7/10 |

This table clearly illustrates that the initial investment in USA-made jeans offers exceptional long-term value.

B. Design Innovation as a Value Driver

Stylish Versatility:

American denim is designed to be as fashionable as it is functional. Whether you’re dressing up for a night out or keeping it casual, these jeans adapt to your lifestyle seamlessly.

Customization Options:

Thanks to OEM/ODM services, consumers can get jeans tailored to their exact body measurements and style preferences. From men’s blue jeans made in USA to specialized designs for women, custom orders guarantee a perfect fit and look.

C. Social and Ethical Value

Purchasing with a Conscience:

Investing in ethically produced jeans means supporting fair labor practices and environmentally sound production methods—a win-win for you and the planet.

Consumer Loyalty:

Buyers of USA-made jeans often become repeat customers, not just because of the product’s durability, but because they value the ethical standards behind the brand. This loyalty boosts the brand image and adds intangible value to your purchase.

D. Lifestyle and Usage Statistics

Real-World Applications:

American denim is designed to perform—whether you’re working, enjoying a concert, or embarking on an outdoor adventure. Recent surveys reveal high satisfaction across various lifestyle scenarios.

Consumer Data Overview:

| Usage Scenario | Satisfaction Rating (1–10) | Percentage Preferring USA-Made (%) |

| Everyday Casual Wear | 9 | 70% |

| Social/Concert Settings | 8 | 60% |

| Outdoor/Activity Wear | 9 | 75% |

These statistics support the notion that USA-made jeans deliver both performance and style, making them a smart choice for diverse daily needs.

6. How Does the OEM/ODM Model Enhance USA Denim Manufacturing?

Featured Snippet:

The OEM/ODM model revolutionizes USA denim production by offering bespoke, end-to-end solutions that integrate design, development, and production, catering flexibly to both small-scale orders and mass production needs.

Dive Deeper: The Advantages of OEM/ODM in American Denim

Tailor-made production is one of the key reasons why American denim continues to lead the market:

A. Customization and Flexibility

Tailor-Made Designs:

OEM/ODM services allow brands to collaborate with manufacturers to create unique denim styles. This means whether you need intricate detailing or a specific cut, the production line adapts to your vision.

Low Minimum Orders:

The flexibility in order size—with minimum orders as low as 30 pieces—enables small businesses and emerging brands to test new designs without the risk of large inventory commitments.

B. Integrated Production Process

End-to-End Production:

From the initial design phase through prototyping and final production, the OEM/ODM model streamlines the entire workflow. This integrated approach shortens lead times and ensures consistent quality.

Seamless Quality Control:

Incorporating design adjustments and quality checks early in the process minimizes errors. Statistical feedback mechanisms ensure that each production cycle meets the precise standards expected in American denim.

C. Building Long-Term Partnerships

Mutually Beneficial Collaborations:

Long-term collaborations between manufacturers and brands lead to more consistent quality, faster innovation, and a stronger market presence. These partnerships often result in a win-win situation, where both parties benefit from shared expertise and reliable production schedules.

D. Data-Driven Product Development

Continuous Feedback Loop:

With every batch, manufacturers collect data from quality inspections and consumer feedback. This information is crucial for iterative improvements, significantly reducing production errors by up to 25% and cutting lead times by 30% in some cases.

Comparative Performance Table:

| Production Metric | Traditional Methods | OEM/ODM Integrated Process | Improvement (%) |

| Production Errors | Higher incidence | Lower due to feedback | Up to 25% reduction |

| Lead Time | Longer cycles | Streamlined processes | Up to 30% faster |

| Customization Flexibility | Limited options | Tailor-made solutions | Highly flexible |

This data-driven approach empowers manufacturers to consistently deliver high-quality, innovative denim tailored to your brand’s unique needs.

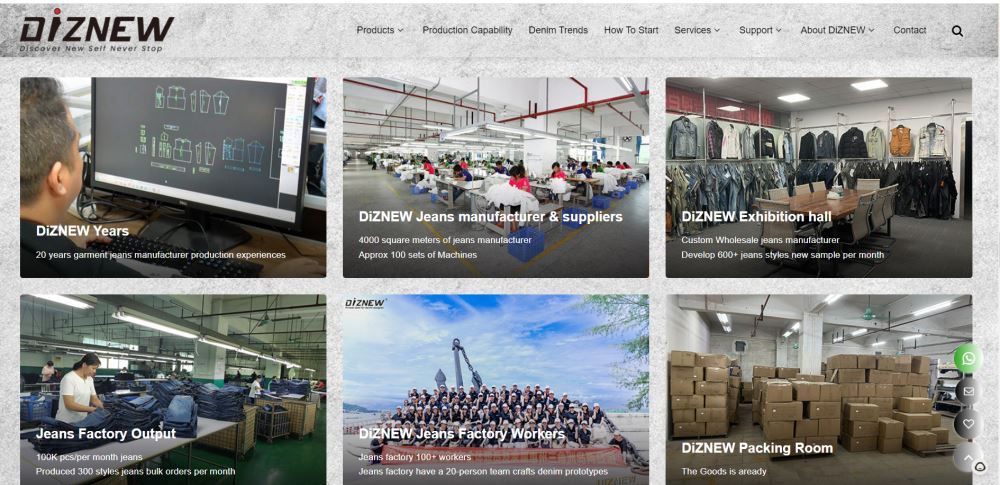

Conclusion: Partner with DiZNEW for Your Custom Denim Needs

USA-made jeans are much more than just a fashion statement—they represent a fusion of heritage, modern technology, and a deep commitment to sustainability and ethical practices. From the meticulous design process and robust production techniques to the nuanced customization options available through OEM/ODM services, American denim sets the standard for quality and durability.

If you're looking to elevate your brand with jeans that speak volumes of innovation and authenticity, consider the advantages that USA-made denim brings to the table. DiZNEW stands ready to provide you with tailored, high-quality denim solutions that meet your specific needs. Whether you're a small startup or an established brand seeking fresh ideas, contact us today for a personalized quote and consultation. Let’s collaborate to create the next iconic piece of American denim—crafted with precision, driven by innovation, and built to last.

FAQ'S

1.Is Levi made in the USA?

Most Levi’s jeans are manufactured overseas (e.g., Mexico, Bangladesh, China), but select premium lines like Levi’s Vintage Clothing (LVC) and limited-edition releases are made in the USA (partner factories in California, Tennessee) using heritage techniques—ideal for denim enthusiasts seeking small-batch American craftsmanship. Check product descriptions or labels for "Made in USA" verification.

2.Are Wrangler jeans made in the USA?

Most Wrangler jeans are produced overseas (Mexico, Asia), but select heritage/workwear styles (e.g., Wrangler Icons, Rigid Workwear) are still made in the USA (Greensboro, North Carolina), blending small-batch craftsmanship with their Western legacy. Check labels for "Made in USA" tags or verify via Wrangler’s official product details.

3.Are any jeans made in the United States?

Yes, several U.S.-made jeans brands thrive:

Heritage Revival: Levi’s Vintage Clothing (LVC) and Wrangler Icons (select styles).

Artisanal Craft: Raleigh Denim, Tellason, Imogene + Willie (handmade in workshops).

Workwear Legacy: Carhartt (Detroit-made lines), Round House (Oklahoma workwear).

Premium Selvedge: Shockoe Atelier (Virginia), Left Field NYC (domestic denim).

Prioritizing U.S.-sourced materials (e.g., Cone Mills heritage fabrics) and ethical labor, these brands blend small-batch quality with timeless durability—check labels for "Made in USA" verification.

Men's baggy ripped jeans featuring silver studs and an embroidered design, offering a bold streetwear vibe with a distressed look.

Custom Blue denim shorts with crystal detailing, blending luxury and street style. Stand out with this personalized denim design.

Custom ripped distressed denim jeans with embroidered stitching patches, chain details & raw edges for a bold streetwear look.

Custom shredded jeans with embroidered stitching and drawstring details. Rugged, stylish, and streetwear-ready.