The Ultimate Guide to Launching Your Denim Brand: From Design to Wholesale

- Share

- Issue Time

- Feb 25,2025

Summary

Launch your denim brand with expert guidance—fabric, design, branding & production. DiZNEW offers custom jeans with low MOQs. Contact us today!

How to Make Your Own Jeans Brand: 2025 Guide for Designers & Wholesalers

Step 1: Fabric Selection - Choosing the Right Denim

Understanding 12 oz Denim Jeans

Imagine your denim fabric as the very foundation of your brand—sturdy, dependable, and full of potential. A 12 oz denim is like a well-balanced artist, blending durability and comfort effortlessly. Whether it's a timeless straight-leg or a bold oversized fit, this fabric weight is ready to shape your dream designs.Imagine your denim fabric as the very foundation of your brand—sturdy, dependable, and full of potential. In usual,12oz denim fabric suit for most of jeans brands.If you want to more thick fabric,you can choose 14 oz denim fabric is ok.

selvedge denim

Using selvedge denim can increase the charm of your brand, but the disadvantage is that the cost of selvedge denim is higher than.

Global Premium Denim Suppliers

Denim has its own VIP circle, with suppliers from around the world offering unique qualities. Picture a global map dotted with legendary fabric houses:

Japan – The guardian of selvage denim, deep indigo hues whispering stories of craftsmanship.

Italy – The luxury maestro, spinning high-end stretch denim that molds like second skin.

Turkey – The sustainability pioneer, balancing affordability with eco-conscious production.

China – The efficiency expert, seamlessly handling both small and large orders with precision.

Step 2: Design Techniques - Crafting Signature Styles

Mastering Acid Wash Cargo Jeans

Acid-wash cargo jeans are like rebellious trendsetters—they never fade into the background. Their vintage charm and streetwear edge comes from a meticulous process:

Pre-wash Preparation – A blank denim fabric, ready for transformation.

Chemical Application – Pumice stones soaked in bleach become the artist's brush denim jeans.

Neutralization & Rinsing – The balancing act to prevent over-fading.

Final Finishing Washed – A gentle touch of softeners, ensures a premium feel.

Cost Analysis: Comparing Different Washing Techniques

| Washing Method | Cost Level | Environmental Impact |

Acid Wash | Medium | Moderate |

Stone Wash | High | High |

Ozone Wash | Low | Eco-Friendly |

| Plain wash | Low | Eco-Friendly |

Curious about sustainable denim? Download our exclusive white paper to explore eco-friendly alternatives.

Step 3: Brand Development - Establishing Your Identity

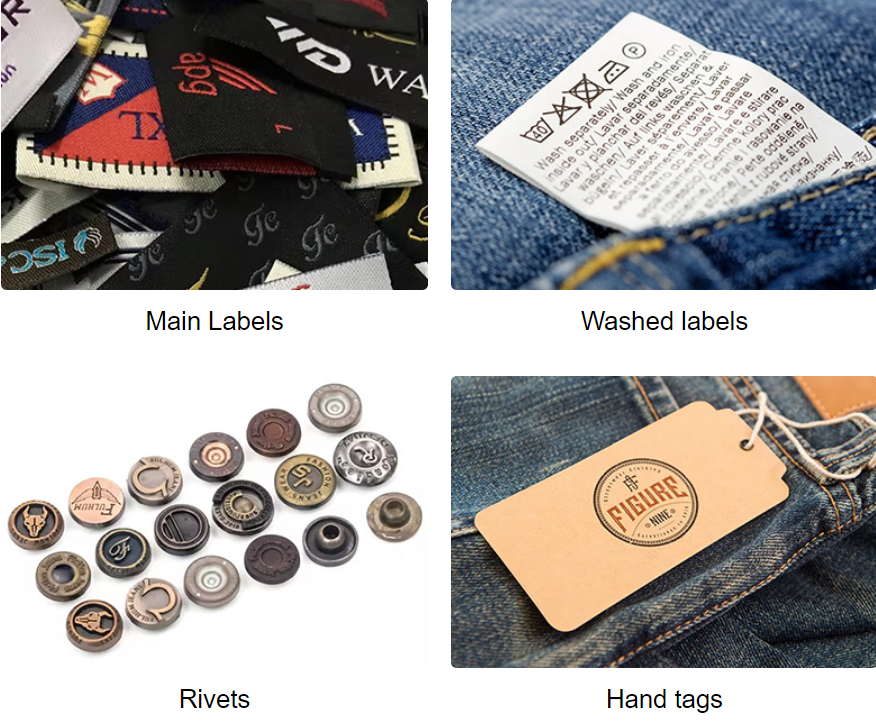

Custom Labels & Branding

Your brand is your signature, and every detail matters. Imagine your jeans telling a story through:

Leather patches – The story teller of premium and vintage aesthetics.

Woven labels – The subtle signature of minimalist, modern branding.

Hand tags – A firm handshake between your brand and the customer.

Interactive MOQ Calculator

Want to crack the code of minimum order quantities? Our interactive MOQ calculator helps you find the perfect balance based on:

Step 4: Scaling Production - Finding the Right Jeans Manufacturing

Blue Brand Jeans Manufacturing

Finding a manufacturing partner is like choosing a dance partner—you need perfect rhythm and understanding. Consider:

Small batch capabilities – Ideal for testing the waters before a big dive.

OEM services – Tailored production for those ready to take over the fashion stage.

Sustainability practices – A conscious brand is a strong brand.

Looking for blank jeans wholesale? Your perfect match might be just a chat us right now.

Step 5: Marketing & Sales - Maximizing Jeans Brand Visibility

Content Marketing

Search engines are like talent scouts—give them the right signals, and they’ll put you in the spotlight. Focus on:

Blog Content – Articles like "How to washing jeans" build credibility and traffic.

YouTube Videos – Show your brand jeans Videos.

Instagram – Promote your brand,tell your brand story and let more people know.

Final Thoughts

Launching your denim brand is like crafting a masterpiece—every step shapes the final vision. From selecting the perfect fabric to branding and scaling, your journey is one of creativity, precision, and passion.

Why Choose DiZNEW as Your Denim Manufacturing Partner?

Meet DiZNEW, your trusted companion in the denim world. We don’t just manufacture jeans—we breathe life into your brand vision. With our robust supply chain, we cater to both emerging designers and established labels, offering flexibility from 30 pieces per style to large-scale bulk production. Whether you're just sketching your first design or expanding your brand, DiZNEW stands ready to support your journey.

Let’s turn your denim dreams into reality—contact us today!

FAQ'S

1.How much does it cost to start a jeans company?

Startup Costs for a Jeans Brand (2025 Industry Benchmark) Initial investments range from $5,800-$17,000 for online-focused brands (small-scale production) to $64,500-$131,300 for physical retail setups, covering prototyping ($800-$2,500/design), fabric sourcing, and e-commerce platforms ($2,500-$6,000)

2.How do you manufacture jeans?

Jeans Manufacturing Process Overview Premium denim production begins with pattern cutting (accuracy ±1mm), followed by lockstitch assembly (12-14 stitches/inch) using reinforced seams. Post-sewing treatments include enzyme washing (3-5 cycles) and laser distressing (50-200W power settings), with final quality checks covering 28+ durability parameters。

3.What do you need to make jeans from scratch?

Essential Components for Custom Jeans Production

Core materials: 12-14oz selvedge denim (width 58-60"), reinforced topstitch thread (Tex 40-60), and copper rivets (5-8mm diameter). Pattern-making requires French curve rulers (±0.5mm precision) and laser cutting machines (120W power) for 0.2mm cutting accuracy.