Submit Clothing Designs to Manufacturers | Step-by-Step Guide

- Share

- Issue Time

- Apr 20,2025

Summary

Learn how to professionally submit clothing designs to manufacturers, from prototyping to tech packs. Streamline production and avoid costly error

How to Submit Clothing Designs to a Manufacturer?

It should not be difficult to get your ideal jeans design from drawings to wearing them. Strengthen your chances for obtaining high-quality denim by sending detailed designs to everyone regardless of your industry experience.

The first step in creating mass production includes developing a rock-solid tech pack containing materials specifications and measurements with stitching details alongside vectorized file types and high-resolution images that users need to select their manufacturer or factory platform and determine minimum order quantities, pricing, intellectual property protections and sustainability terms before final contract signing.

1. What materials and design specifications should I include in my tech pack?

Materials and design specifications

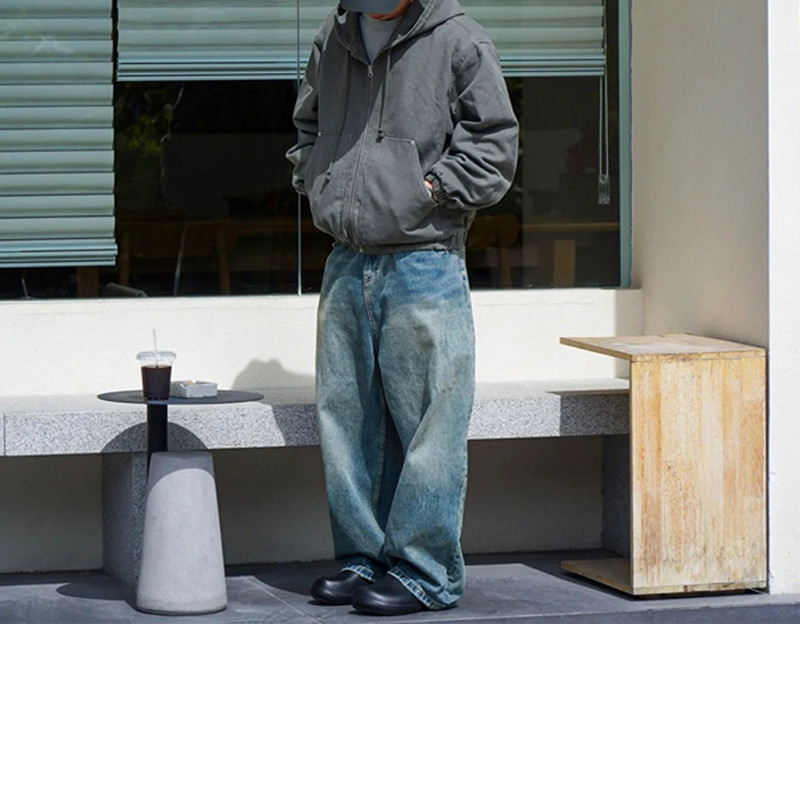

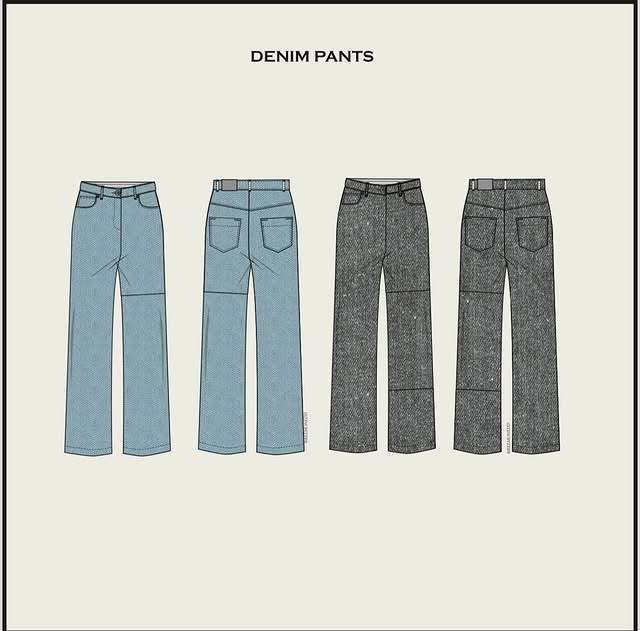

A clean denim design sketch that captures the core silhouette and styling—perfect as a visual starting point for communicating your concept to manufacturers.

List every detail from fabric composition to stitch type so the factory can nail your design on the first try.

Dive Deeper

1.Fabric breakdown

·Fiber content (e.g., 98% cotton, 2% spandex)

·Weight (e.g., 12 oz denim)

·Finish (raw, stone‑washed, enzyme wash)

2.Hardware & trims

·Rivets (material, plating, size)

·Buttons (logo‑embossed metal, matte black)

·Zippers (brand, length, pull style)

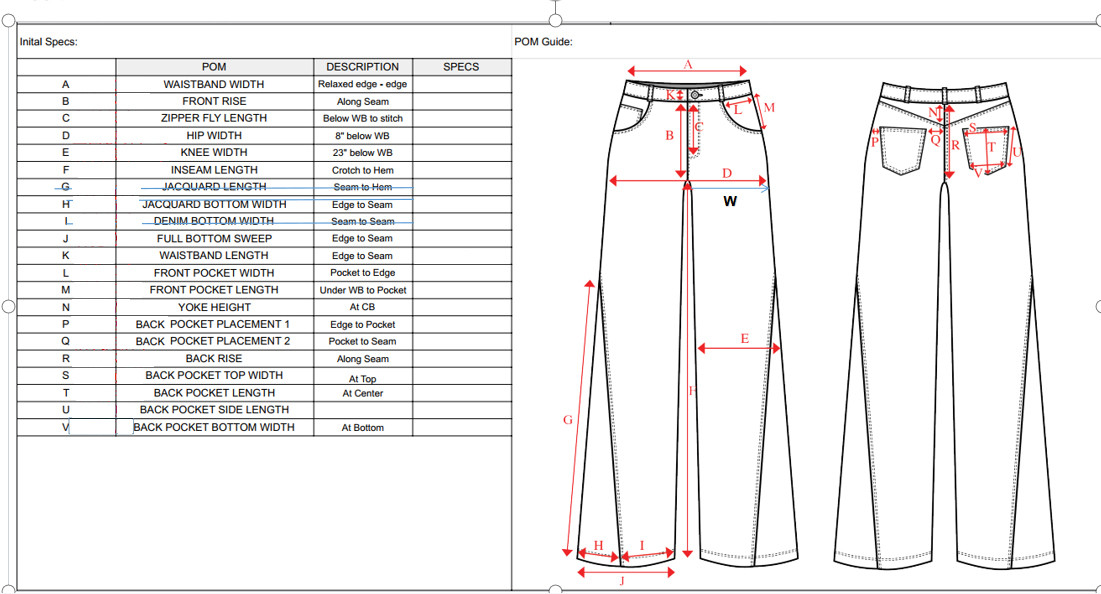

3.Measurements & grading

·The dimensions of waist, hip, rise, inseam require flat measurements with a maximum tolerance of 0.5 centimeters.

·The grading rules for S–XL sizes state that the waist expands by +2 cm per size.

4.Construction details

·Seam types (chain‑stitch vs. lock‑stitch)

·Thread weight and color codes

·Reinforcement points (crotch, pocket edges)

5.Visual aids

·Annotated flats: front, back, side

·The tech pack includes identifiable details for primar elements like the back-pocket stitch pattern and belt-loop width.

·The design documents include images of fabric samples or Pantone reference codes.

Businesses benefit from complete tech pack details which can reduce necessary revisions by 70% through shortened time periods of project modifications.

2.How do I prepare and format my design files for online submission?

Keep your files neat and professional—include clearly named tech packs (PDF), sketches (JPEG/PNG), and measurement charts (Excel). Organizing your folder properly shows manufacturers you're serious and saves everyone time.

Use vector PDFs for line drawings, high‑res JPEGs/PNGs for mood boards, and bundle everything in a single ZIP or cloud folder.

Dive Deeper

1.File formats at a glance

| File Type | Use Case | Specs |

| AI/EPS | Line drawings & flats | Outlines only, no raster |

| PDF (vector) | Universal tech pack sharing | Embedded fonts, linked images |

| PSD | Complex graphics & mockups | Layered, 300 DPI |

JPEG/PNG | Mood boards & textures | 300 DPI, sRGB color space |

2.Naming & organization

·Brand_Style-TechPack_v01.ai

·Folders: /TechPack, /Swatches, /Images, /Measurements

3.Bundling & sharing

·ZIP your entire pack, or

·Upload to Google Drive/Dropbox with “view only” links

4.Quality assurance

·Zoom to 200%—are lines still sharp?

·Double‑check units (cm vs. inches) for every dimension

Pro tip: Clear file structure saves everyone time—no more “Which file is the back‑pocket sketch?” emails.

3. Which platforms and channels can I use to send my clothing designs to get made?

From Etsy to Alibaba to direct factory portals, pick the channel that suits your MOQ, budget, and communication style.

Dive Deeper

1.Platform comparison

| Platform | MOQ Range | Fees & Commissions | Ideal For | Watch Out For |

5–50 pcs | $0.20/listing + 5% sales | Small runs, niche brands | Higher per‑item costs | |

| 100+ pcs | None; direct negotiation | Bulk orders, varied factories | Quality inconsistency | |

| Fiverr | Any (design) | 5% service fee | Quick design tech‑pack help | Not true manufacturing, just design |

| Direct Factory | 30+ pcs | OEM quote | Custom support, low MOQ | Requires vetting & samples |

2.Direct factory portals

·OEM/ODM factories provide online portals to their customers which enable tech pack uploads and sample tracking and enable communication through rep chat.

3.Social sourcing

·Members of LinkedIn groups together with participants of fashion forums can deliver vetted information about factory contacts.

·Both MAGIC in Las Vegas and Canton Fair in China provide physical sample viewing experiences to buyers.

Heads‑up: If you need under-30 MOQ, direct factory contact beats Alibaba’s typical 100‑piece minimum.

4. How do I initiate contact and submit a design to a clothing company or factory?

Shoot over a concise email or portal entry with a quick introduction, your bundled tech pack link, target quantities, and timeline.

Dive Deeper

“Tech Pack Submission: BrandName – 50pcs Denim Jeans”

2.Write a friendly opening

UrbanDenim representative Alex begins by addressing Rep Name with his message. Your neat finishing work strikes me as exceptional so I want to produce 50 pieces of our E-Series jeans. The document tech pack joins with the mood board now requires your preliminary cost information and lead time information.

3.Attach and describe assets

·Include a bulleted checklist:

·Tech pack ZIP

·Mood board (JPEG)

·Size spec sheet (PDF)

4.Ask clear questions

·“What’s your per‑unit price for 30–100 pcs?”

·“Do you require a deposit? If so, how much?”

·“Can you handle stone washing in‑house?”

5.Follow‑up strategy

·Wait 5–7 business days, then send a polite nudge.

If no response after 10 days, try ·WhatsApp or WeChat (common in Asia).

Textual requests simply asking for prices through one-line emails frequently fail to generate any response.

5. What minimum order quantities, pricing structures, and cost considerations should I discuss?

Compare MOQ tiers, per‑unit costs, setup fees, and hidden expenses in a single table to keep your budget on track.

Dive Deeper

1.MOQ & pricing at a glance

| Order Qty | Unit Price (USD) | Setup/Tooling Fee (USD) | Lead Time (weeks) |

30–100 pcs | $15.00–$18.00 | $200 | 4–6 |

| 101–500 pcs | $10.00–$14.00 | $300 | 6–8 |

| 501–1000 pcs | $8.00–$10.00 | $500 | 8–10 |

| 1001+ pcs | $6.00–$8.00 | $800 | 10–12 |

2.Hidden costs you shouldn't miss

·Shipping & duties: The payment agreement regarding shipping costs and duties between importer and exporter exists as FOB or CIF delivery methods.

·Sample fees: Each style of prototype costs between $50 and $100.

·Revision rounds: Additional sample rounds entail a payment of $20 to $30.

3.Money‑saving hacks

·Combining different style options within one production batch enables achievement of higher price levels.

·The supplier should provide yearly discounts for bulk orders.

·Find out if production opportunities exist through joint purchasing agreements between small brands.

Fun fact: Increasing from 100 to 200pcs can slash your per‑unit cost by up to 25%.

6. How can I protect my designs and ensure intellectual property security?

Lock down NDAs, watermark drafts, and embed clear IP clauses in your production contract.

Dive Deeper

1.NDA essentials

·Scope: All sketches, tech packs, and proprietary processes.

·Term: At least 2 years, with defined penalties for leaks.

2.IP in contracts

·Ownership: You retain 100% design rights.

·Non‑compete: Factory can't produce your jeans for others for X months.

3.Digital safeguards

·Share low‑res, watermarked flats until agreements sign.

·Track file downloads via cloud history.

4.Factory vetting checklist

·Request references of their client work and pages showing sample garment collections.

Reality check: 1 in 5 small brands report copycat leaks—strong legal safeguards are non‑negotiable.

7. What steps follow after selecting a manufacturer—sample review, revisions, and final agreements?

After choosing your manufacturer, the real work begins—review the prototype, test its durability and fit, and note every issue, no matter how small. Once revisions are approved, finalize the contract and kick off production with confidence.

A manufacturer must obtain approval for prototypes through wash and fit testing before contractual documentation allows production to begin.

Dive Deeper

1.Prototype review

·Check fit on multiple body types.

·The examination must focus on both stitch strength and hardware finishing quality.

2.Performance testing

·Colorfastness: 10‑wash test for fading.

·Shrinkage: Pre‑wash vs. post‑wash dimensions.

3.Feedback & revisions

·A collection of issue photographs along with relevant notes goes into the compilation.

·Update the tech pack design with red ink so the specifications remain clear.

4.Final contract

·Milestone payments: 30% deposit, 40% pre‑run, 30% on shipping.

·Penalties: 0.5% per week delay, up to 5%.

5.Pre‑production checklist

·Raw material sign‑off (fabric, trims).

·QC plan: Random 5% inspection, defect tolerance ≤2%.

Bottom line: A structured sample‑to‑sign‑off process cuts quality defects by up to 60%.

8. Are there sustainable practices I should inquire about in production?

Sustainability isn't just a trend—it’s a responsibility. Ask your manufacturer about water-saving washes, eco-friendly fabrics, and waste-reduction practices to make sure your jeans are better for the planet, not just the people.

Ask about water‑saving dyeing, organic/recycled fibers, and waste‑reduction programs to make your jeans eco‑friendly.

Dive Deeper

1.Material sourcing

·Organic cotton (GOTS certified) vs. conventional cotton.

·Recycled PET blends for stretch denim.

2.Eco‑dyeing processes

·Laser fading cuts water use by ~80%.

·Closed‑loop systems recycle 90%+ of wash water.

3.Waste & energy

·Off‑cut recycling: patchwork accessories or insulation.

·Solar‑powered facilities reduce carbon footprint.

Certifications to look for

| Certification | Focus Area | Why it matters |

| GOTS | Organic textiles | Full supply‑chain traceability |

| Bluesign | Chemical safety | Safer chemicals, lower environmental impact |

| Fair Trade | Labor conditions | Ensures fair wages and working hours |

Why go green? 73% of consumers say they’d pay more for sustainable clothing—eco‑practices boost both planet and profits.

1.How do i send clothing design to a manufacture?

The proper method to share clothing designs with manufacturers involves compiling an in-depth tech pack containing flat sketches alongside measurements and fabric attributes and Pantone reference numbers followed by cloud-based storage shared through Google Drive or Dropbox while sending a business-oriented introductory email that defines production schedules and minimum order requirements – maintain professional file types (.AI/.PDF/.DXF) alongside requiring physical sample validation prior to complete manufacturing.

2.How to get your design manufactured?

You must transform design into production through three stages which begin with technical package creation of CAD files and spec sheets and BOM then continue with manufacturer selection from Alibaba or HBX searching for 'ODM apparel factory or private label prototyping' followed by MOQ negotiation for 3D sampling services then concluding with a legally binding PPAP agreement before virtual factory audits done via Zoom ensure manufacturing compliance.

3.Do i need to copyright my clothing designs?

You don't need to copyright your clothing to copyright your clothing designs, but protecting original elements through copyright, trademark or design patent can help prevent others from copying your brand, giving you stronger legal rights and a competitive advantage.

Conclusion

Submitting your apparel designs to manufacturers doesn’t have to be a maze of confusion and endless emails. By carefully preparing your technical package, organizing your documents, choosing the right platform or factory to sell to, and establishing clear order and pricing terms, you’ll set yourself and your denim dreams up for success. Remember to protect your intellectual property with a nondisclosure agreement, proceed step by step with sample approval, and adhere to sustainable practices that meet the demands of today’s eco-friendly consumers.

Ready to take the leap? Contact DiZNEW for a personalized quote and let us take your sketches, stitch by stitch, into a finished product on the runway.

Custom Blue denim shorts with crystal detailing, blending luxury and street style. Stand out with this personalized denim design.

Discover premium DiZNEW denim jeans with decorative studs for a sparkling, stylish look. Order today!

These designer denim shorts for men feature intricate decorative stitching and rivet details, perfect for streetwear fashion. The wide-leg silhouette adds a bold look, ideal for trendsetters.

Wholesale graffiti-style digital print jeans—bold streetwear with vibrant artwork for fashion brands and retailers.