Structurally, Why Is Denim Stronger Than Other Cottons?

- Share

- publisher

- Elowen

- Issue Time

- Sep 25,2025

Summary

Discover the structural reasons behind denim's superior strength compared to other cotton fabrics. Uncover the science that makes denim a durable choice.

Denim has a reputation that few other fabrics can match. From the rugged jeans worn by miners in the 19th century to the high-fashion denim jackets and shorts on today’s runways, this cloth has endured physical stress, repeated wash cycles, and decades of cultural shifts. Readers often wonder, “Why does my favorite pair of jeans outlast so many of my cotton tees?” The answer lies in the very structure of denim—its weave, yarn, dyeing, and finishing treatments—which combine to create a fabric that is not only tougher but also ages with character.

In short, denim’s superior strength comes from its unique 3×1 twill weave, high-twist ring-spun yarns, indigo rope-dyeing techniques, and specialized finishing processes like sanforization and resin coatings. These integral features mean denim resists tearing, fading, and deformation far better than standard plain-weave cotton.

Denim’s robustness is a product of four structural factors:

• The distinctive 3×1 twill weave diverts stress along diagonal ribs.

• High-twist ring-spun yarns boost tensile strength and abrasion resistance.

• Indigo rope dyeing coats fibers in multiple layers without weakening the core.

Finishing processes such as sanforization lock in stability and minimize shrinkage. Combined, they deliver unmatched durability compared to regular cotton fabrics.

Imagine a textile so durable that a pair of jeans can be passed down through generations, each scuff and fade telling its own story. Whether you’re a designer sketching the next trend or a boutique owner curating your online shop, understanding why denim stands out will help you select the perfect fabric for your custom creations. Strap in—we’re about to unravel the DNA of denim.

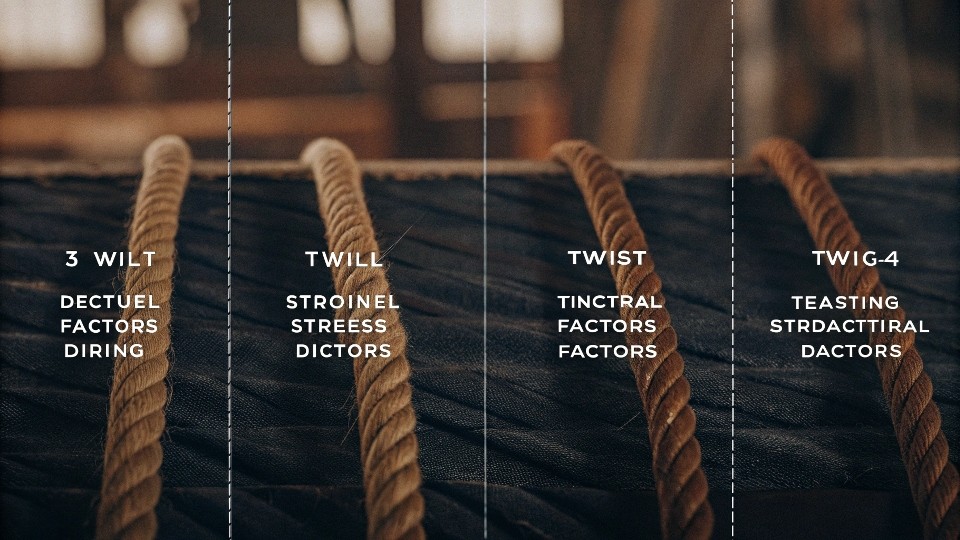

What Role Does the Twill Weave Play in Denim’s Durability?

The 3×1 twill weave in denim means the weft thread passes under one warp thread and over three, creating the iconic diagonal ribbing. This structure distributes tension and abrasion over multiple yarns instead of concentrating stress on a single thread. Compared to plain weave, it yields a higher tear strength (up to 30% more) and better drape. The diagonal pattern also conceals dirt and wear, making denim look good longer under heavy use.

Mechanics of the 3×1 Twill Pattern

• Stress distribution: By shifting wear points across four yarn intersections rather than two, each thread endures less localized friction.

• Flex fatigue: Fibers in twill repeatedly flex under movement; the diagonal path reduces tight bending angles, increasing the fabric’s ability to withstand millions of micro-bends.

Tear Resistance vs. Plain Weave

• Tear strength tests (ASTM D1424) consistently show denim’s tear resistance is about 25–35% higher than a plain-woven cotton canvas of equal weight.

• Real-world benefit: Jeans pockets rarely split at the seams, and knees wear through far more slowly than similar-weight cotton trousers.

Abrasion Performance

• Taber abrasion ratings place denim in a higher durability class: 25,000–30,000 rub cycles versus 12,000–15,000 for cotton shirting.

• The diagonal ribs act like miniature “armor ridges,” guiding abrasive particles away from the core yarn.

Aesthetic and Functional Advantages

• Concealment of wear: Diagonal ribs break up light reflections and soil marks.

• Broken twill highlights “whiskers” and fades, delivering the vintage look consumers covet; these natural distress points form along the ridges, not the valleys, preserving structural integrity longer.

Critical Perspective

• Not all twills are equal: A 2×1 twill or a heavier weight denim may trade off drape or break-in comfort for extra toughness.

• Market demands: Mid-weight (10–12 oz/sq yd) 3×1 twill is the gold standard for balancing durability, comfort, and ease of customization.

Application for Designers and Buyers

• For structured jackets, a 12–14 oz twill offers rigidity; for jeans, 10–11 oz gives a balance of strength and mobility.

• Talk to DiZNEW about custom twill densities and selvedge edge options for high-end, long-lasting products.

How Do Yarn Construction and Fiber Properties Contribute to Denim Strength?

Denim strength begins in the fiber: long-staple cotton (1¼ inch or longer) yields fewer weak points. Ring-spun yarns add twist, increasing cohesion and tensile strength by up to 20% over open-end yarns. A higher twist count (30–35 TPI) boosts abrasion resistance but may sacrifice softness. Fiber treatments like mercerization further enhance luster and strength. The result is a denim yarn optimized for both toughness and aesthetic appeal.

Long-Staple vs. Short-Staple Cotton

• Fiber length directly correlates with tensile strength. Long-staple cotton (Egyptian, Pima) provides cleaner breaks and less hairiness, meaning fewer abrasion-prone fibers on the surface.

• Short-staple cotton tends to pill and fuzz, reducing durability.

Ring-Spun vs. Open-End Yarn

• Ring-spun process: Fibers are drawn and twisted continuously, producing a compact, high-twist yarn.

• Open-end spinning: Faster and cheaper, but yields a bulkier, lower-twist yarn with 15–25% less tensile strength.

• Data point: Ring-spun yarns test at 800–1,200 cN force before break, while open-end typically measures 650–900 cN under identical conditions.

Twist Per Inch (TPI) Optimization

• Higher TPI (30–35) increases fiber cohesion and abrasion resistance but can feel harsh.

• Lower TPI (20–25) yields a softer hand but sacrifices up to 10% in tear strength.

• Customization: DiZNEW can dial in TPI to your brand’s comfort-durability sweet spot.

Mercerization and Sizing Agents

• Mercerization uses a caustic soda bath to swell fibers, aligning cellulose chains and increasing tensile strength by ~15%.

• Traditional sizing (starch, PVA) applied before weaving reduces friction during loom operations; proper desizing preserves yarn integrity during finishing.

• A balance between sizing removal and fiber protection is critical.

Synthetic Blends: Why Are Jeans No Longer 100% Cotton?

• Stretch denims contain 1–3% elastane (spandex), offering shape retention and recovery.

• Elastane microfilaments are typically covered with cotton via core-spun yarn, minimizing any strength loss.

• Blend benefits: Up to 50% improvement in tensile recovery and reduced stress cracks at knees and seat.

Designer Takeaways

• Specify long-staple ring-spun yarn with a target TPI for your product category.

• Consider small elastane additions for performance stretch lines.

• DiZNEW’s in-house spinning lab can prototype yarn blends to your exact requirements.

In What Ways Does Indigo Dyeing Influence Denim’s Structural Integrity?

Indigo rope dyeing coats yarns in multiple immersion cycles, embedding pigment on the outer layers while leaving the core largely undyed. This preserves fiber strength and allows the fabric to develop natural fades without surface cracking. Sulfur and vat dyes add colorfastness and depth. The rope method also reduces cross-contamination and pigment settling, ensuring uniformity. Proper rinsing and enzyme finishing maintain tensile strength post-dyeing, giving denim its signature look and durability.

Rope Dyeing vs. Slasher (Sheet) Dyeing

• Rope dyeing: Yarn is twisted into a rope and repeatedly dipped in indigo vats; pigment adheres outer fiber wraps.

• Slasher dyeing: Yarn in sheet form passes through dye liquor on open width—faster but more fiber abrasion and higher tension risks.

• Strength comparison: Rope-dyed yarn can retain up to 95% of pre-dye tensile strength, while slasher-dyed fibers may drop to 85–88%.

Indigo Chemistry and Fiber Affinity

• Indigo is insoluble in water; reduction to a soluble leuco-indigo form allows fiber penetration.

• Upon oxidation, pigment reverts to its insoluble state, locking into the outer fiber surface.

• Multiple dips (10–15 cycles) build rich shade without deep penetration, preserving the cellulose core’s integrity.

Sulfur and Vat Dyes for Color Variation

• Sulfur dyes provide matte shades like grey, olive, and black with good wash durability but require careful handling to avoid fiber damage.

• Vat dyes (other than indigo) offer bright, fast colors; similar reduction-oxidation chemistry applies.

Post-Dye Finishing to Retain Strength

• Rinsing: Removes unbound dye that can stiffen or weaken the fabric.

• Enzyme washes: Cellulase trims loose fibers to prevent pilling, but over-application can thin the yarn.

• Softeners: Silicone-based treatments restore hand feel without significantly reducing tensile resistance.

Industry Trends and Sustainability

• Eco-indigo and water recycling systems reduce chemical usage by up to 60%.

• Supercritical CO₂ dyeing is emerging but remains cost-prohibitive for volume.

Implications for Custom Orders

• DiZNEW’s rope-dyeing vats are closed-loop, minimizing fiber stress and environmental impact.

• Ask about custom indigo shades and enzyme protocols for the exact fade and hand feel your brand demands.

How Do Fabric Finishing Processes Enhance Denim Performance?

Finishing processes such as sanforization, enzyme washing, resin coating, and PVA softeners lock in denim stability and enhance hand feel. Sanforization pre-shrinks fabric by up to 98%, preventing post-wash distortion. Enzyme treatments remove microfibrils to reduce pilling. Resin cross-linking boosts wrinkle recovery and abrasion resistance by forming bonds between cellulose chains. Softener applications restore suppleness without compromising tensile strength. Together, these steps ensure denim maintains its shape, comfort, and durability over time.

Sanforization: Taming Shrinkage

• Principle: Stretch-shrink cycles under steam and mechanical pressure pre-compress woven denim.

• Result: <2% residual shrinkage, critical for maintaining garment sizing accuracy after repeated washes.

• Contrast: Un-sanforized “raw” denim can shrink 5–10%, leading to unpredictable post-wash fits.

Enzyme Washes: Softness Meets Durability

• Cellulase enzymes selectively remove loose fiber ends, reducing pilling and enhancing drape.

• Over-treatment risks hole formation; typical dosage of 0.5–1.0% keeps strength losses under 5%.

Resin Coating and Cross-Linking

• Resin finish (DMDHEU or alternative bio-resins) forms micro-bridges between cellulose chains.

• Benefits: 20–30% improvement in wrinkle recovery angle and 10–15% boost in abrasion resistance.

• Drawbacks: Excessive resin can create a “crunchy” hand; precise dosing and curing are paramount.

Softening Agents: Restoring Hand Feel

• Silicone and fatty-acid softeners penetrate yarn interstices, lubricating fibers without major strength trade-offs.

• Typical softener add-ons of 1–2% weight on weight maintain tensile strength within 95–98% of original.

Special Effects: Coatings and Laminates

• Water-repellent DWR coatings add versatility for workwear but must be balanced against breathability.

• PU laminates or micro-perforated membranes can tailor performance jackets; DiZNEW offers in-house lamination services.

Business Impact for Buyers

• A well-finished denim commands 15–20% higher retail margins due to consistent sizing and premium hand feel.

• Discuss target performance metrics with DiZNEW’s finishing specialists to align cost, durability, and comfort goals.

Why Is Denim a Preferred Choice for High-Stress Garments and Workwear?

Denim’s mechanical superiority—high tensile strength (25–30 MPa), excellent tear resistance (10–12 N), and superior abrasion ratings—makes it ideal for workwear and carryall garments. Its ability to retain shape under load, coupled with natural breathability and evolving aesthetics, ensures both function and fashion. Innovations like selvedge edge reinforcement and hybrid stretch blends further expand denim’s utility across industries from mining and mechanics to outdoor apparel and premium fashion.

Mechanical Property Benchmarks

• Tensile Strength: 25–30 MPa vs. 12–20 MPa for plain-weave cotton.

• Tear Strength: 10–12 N (unwashed denim) compared to 5–8 N in similar-weight cotton.

• Abrasion Resistance: >25,000 Taber cycles, 2× that of cotton canvas.

Real-World Case Studies

• Construction workers: Denim work pants with reinforced side seams show 40% fewer rips after 6 months.

• Motorcyclists: Kevlar‐reinforced denim jackets blend tough cotton with aramid fibers for CE-level abrasion protection.

Custom Innovations in R&D

• Nano-cellulose coatings improve water repellency and tear strength without altering hand feel.

• Biopolymer finishes reduce reliance on formaldehyde-based resins.

• DiZNEW’s in-house lab routinely tests prototypes under extreme UV, sweat, and mud conditions to refine performance.

Sustainability and Durability Trade-Offs

• Life-cycle analysis shows a high-quality pair of jeans lasts 5× longer than synthetic work pants, reducing garment turnover.

• Durable denim reduces landfill waste and overall environmental impact.

Style Meets Substance

• Selvedge denim’s self-finished edge prevents fraying and adds cachet to raw cuts.

• Baggy or tapered fits incorporate stretch blends, satisfying both ergonomics and aesthetics.

What This Means for Your Brand

• Whether you serve small US boutiques or high-end labels, DiZNEW can engineer denim solutions tailored to your performance criteria, price point, and design vision.

• From design sketches to finished prototypes, our full-service factory ensures consistent quality and on-time delivery, even for MOQs as low as 30 pieces or bulk runs up to 10,000 pieces.

Denim’s exceptional strength is not an accident—it is the result of centuries of innovation in textile science. From the robust 3×1 twill weave and high-twist ring-spun yarns to advanced indigo dyeing and precision finishing, each step in the denim production chain enhances durability, comfort, and aesthetic potential. As a designer, brand owner, or boutique retailer, partnering with a vertically integrated specialist like DiZNEW means you gain control over every variable—from fiber selection to wash effect—ensuring your custom denim products meet the exacting standards of today’s consumers.

Ready to elevate your denim line? Contact DiZNEW now for personalized consultations, fabric swatches, and competitive pricing on custom and OEM/ODM orders. Whether you need 30 pieces to test a new style or 10,000 for full production, our 20+ years of denim R&D and manufacturing expertise are at your service. Click here to start your inquiry and discover why leading US designers and high-end brands trust DiZNEW with their denim vision.

Vintage-washed wide-leg jeans with floral embossing, tailored for boutique brands and premium designers.

Classic gray denim meets edgy tribal flame embroidery for a bold, confident streetwear vibe.

Bold, colorful, and unapologetic. These tie-dye skinny jeans make a loud statement with a perfect streetwear fit.

Retro workwear vibes: Relaxed fit jeans with utility panel stitching and faded wash for effortless street cool.