Need a Clothing Tech Pack Designer? | Expert Services

- Share

- Issue Time

- May 8,2025

Summary

Hire expert clothing tech pack designers to streamline production. Ensure precision, speed, and compliance. Get a free consultation now!

Do you need a clothing tech pack designer?

Have you ever watched months of sketching, sampling, and sourcing go down the drain because a factory misunderstood a single seam? In today’s fast-paced fashion world, miscommunication around measurements, materials, and finishes can cost you thousands of dollars—and your brand’s reputation.

Picture this: you launch a limited-edition, rhinestone-studded denim jacket, only to find the stones placed unevenly across dozens of samples. Ouch. Stick around: I'll share how brands like DiZNEW solve these headaches with pro tech pack designers—and how you can, too.

1. What is a tech pack in fashion designing and why does it matter?

A fashion tech pack—often called a garment tech pack or apparel tech pack—is like a recipe card for garments, translating your creative vision into precise, step-by-step instructions.

Dive Deeper

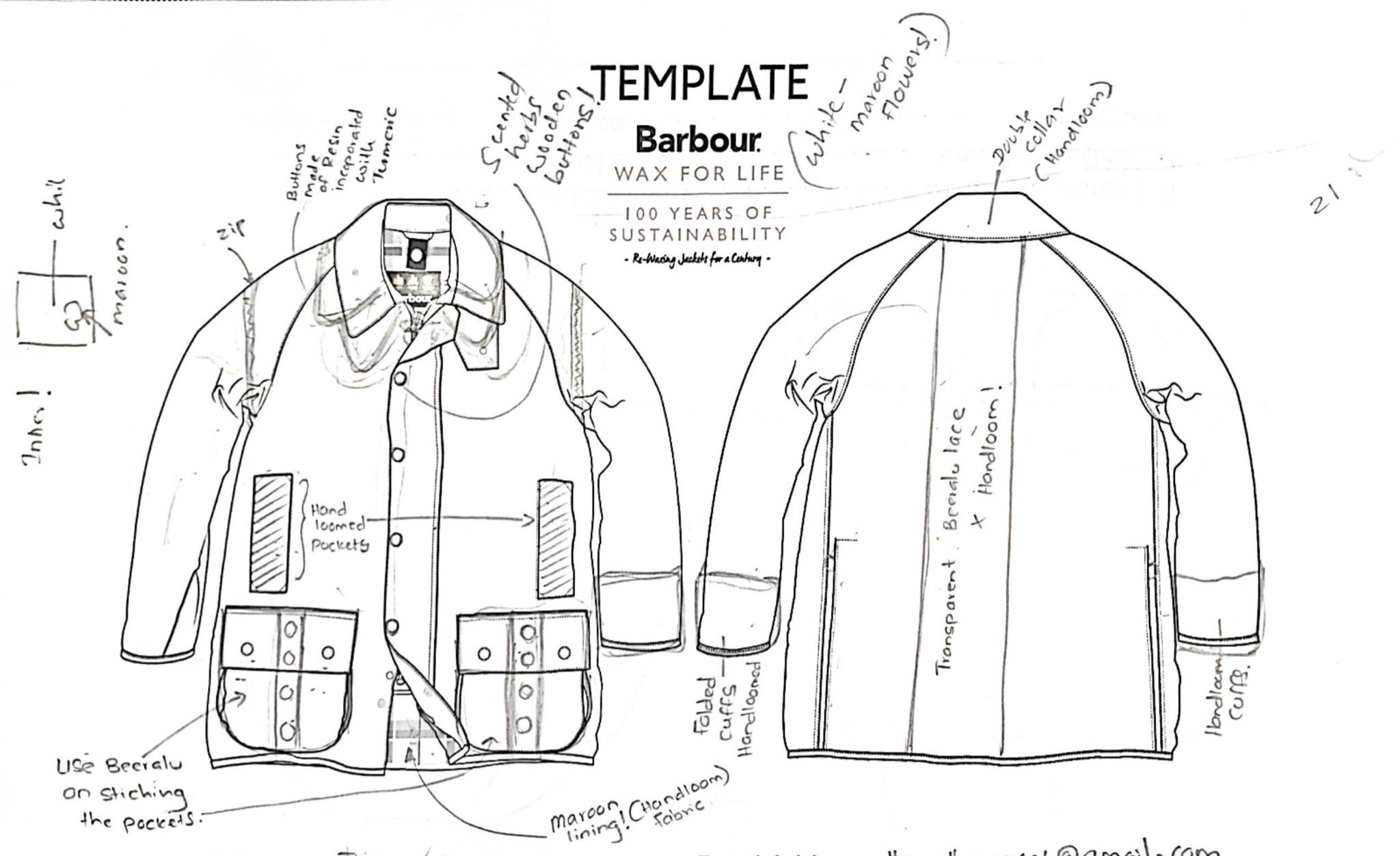

1.1 Core Components of a Fashion Tech Pack

| Component | Description | Why It Matters |

| Flat sketches & CADs | Orthographic views (front, back, side) | Eliminates guesswork on silhouette |

| Measurement spec sheet | Size chart with exact points (e.g., waist, inseam) | Prevents fit surprises in production |

| Materials & trims list | Fabric weight (oz), composition, buttons, labels, etc. | Keeps quality consistent |

Construction details | Seam type, stitch count, reinforcement steps | Ensures garment durability |

Labeling & packaging notes | Hangtags, polybag dimensions, folding instructions | Streamlines final delivery |

Brands using detailed tech pack templates report up to 30% faster sample approvals and 20% lower rework costs.

1.2 Why Every Detail Counts

·Flat sketches: Multiple views catch nuances that a single drawing can’t.

·Spec tolerances: ±0.5 cm tolerance prevents out-of-spec pieces sneaking into bulk.

·Trim callouts: “Gunmetal rivets, 8 mm diameter” versus “metal rivets” can mean the difference between high-end and dollar-store looks.

1.3 Real-World Impact: DiZNEW Denim Drop

When DiZNEW launched its “Urban Flash” denim—complete with hot-stamped logos and contrast topstitching—the clothing design tech pack specified:

·Hot stamp code: YL-HS-002, gold metallic, 0.2 mm thickness

·Stitch density: 8 stitches per 2 cm, using polyester 40 wt thread

·Pocket bag fabric: 80 gsm plain-weave cotton

Result? First-round sample pass rate: 92%, slashing development time by two weeks.

2. Do you really need a tech pack or can you DIY?

Even if you're tempted to DIY, a professional clothing tech pack ensures accurate communication, reduces errors, and saves time—especially in the fast-paced fashion tech pack world where details matter.

If you’re kicking off with a few basic tees, you might tackle a free clothing tech pack template yourself. But for complex styles—especially with low MOQs like 30 pieces—hiring a fashion tech pack designer is worth the investment.

Dive Deeper

2.1 DIY Pros & Cons

| Pros | Cons |

| Zero upfront design fees | Steep learning curve; high risk of errors |

| Full creative control | Longer sampling cycles (2–4 extra rounds) |

| Flexibility to tweak on the fly | Potentially costly material waste |

2.2 When DIY Makes Sense

·Basic jerseys: Plain T-shirts, tank tops, hoodies using a basic tech pack clothing template.

·High MOQs: Factories can absorb minor spec variations over bulk runs.

·In-house expertise: You have seasoned pattern makers or tech designers on staff.

2.3 When to Hire a Fashion Tech Pack Designer

·Low MOQs (≤50 pcs) where each sample is precious.

·Complex constructions: Embroidery, rivets, hot stamps, detachable parts.

·Multi-piece collections: Coordinating outerwear, pants, tops with consistent trims.

2.4 Budget Snapshot

| Service Type | Typical Rate | Notes |

| Freelance designer | $30–$80 /hour | Good for startups; vet portfolios carefully |

| Boutique agency | $500–$2,000 /pack | Higher quality; includes revisions |

| In-house specialist | $45,000–$65,000 /year + benefits | Best for brands with frequent collections |

3. Which free tech pack templates and examples can you download today?

You’ll find plenty of free tech pack templates—PDFs, Excel sheets, Google Sheets—but customization is key. Don’t let a generic template drain your brand’s unique details.

Dive Deeper

3.1 Top Free Template Sources

| Source | Format | Pros | Cons |

Fashionary | PDF | Clean layouts; printable | Not editable without design software |

| Excel | Editable grids; straightforward | Limited sketch space | |

| Google Sheet | Real-time collaboration; version history | Needs customization for trims and QC | |

| ODM2Go | PDF & PPTX | Includes color-board slides | PPTX less common in factories |

3.2 Customization Checklist

①Replace default measurements with your size chart (e.g., waist 28–40 in).

②Insert brand logo and wash code system (e.g., DW-WL-001).

③Add advanced trim fields: leather patches, rhinestones, jacquard labels.

④Include tolerance column (±0.3 cm for critical measurements).

3.3 Editable vs. Static Formats

| Format | Editable? | Collaboration | Version Control |

| PDF | No | Low | Manual |

| Excel | Yes | Medium | Track Changes |

| Google Sheet | Yes | High | Auto History |

4. How do apparel tech pack designers actually build and customize their own packs?

From initial inspiration to final packaging instructions, designers layer sketches, CADs, measurements, fabrics, trims, and QC notes into a unified spec package.

Dive Deeper

4.1 Step-by-Step Workflow

①Mood Board & Concept: Define story, target customer, price tier.

②Flat Sketches/CAD: Draw in Illustrator or capture in CLO 3D.

③Measurement Specs: Base size (e.g., M) then grade across S–XL.

④Material & Trim Sourcing: List mill/fabric codes, button/rivet vendors.

⑤Construction & QC Notes: Specify seam allowances, stitch density.

⑥Packaging & Labels: Call out hangtag design, polybag fold, carton markings.

4.2 Tools of the Trade

| Tool | Function | Ideal For |

Adobe Illustrator | Vector flat sketches | Custom CAD drawing |

| CLO 3D | 3D virtual prototyping | Fabric drape & fit testing |

| Techpacker | Web-based pack builder | Collaborative spec creation |

| Lectra PLM | End-to-end lifecycle management | Large brands & complex lines |

4.3 Customizing for Dresses & Denim

·Tech pack dress specs include skirt flare angle, lining details.

·Denim recipe: Enzyme % and water ratio across wash steps.

·Embellishments: Rhinestone placement grid (10 × 10 dots at 1 cm spacing).

5. What software tools streamline your tech pack clothing design workflow?

Tools like Techpacker and Illustrator make tech pack clothing design faster, clearer, and easier to manage.

From simple drag-and-drop platforms to enterprise PLM, the right app or software cuts spec creation time by up to 50%, automates grading, and reduces errors with built-in checks.

Dive Deeper

5.1 Feature Comparison

| Software | Grading Automation | Collaboration | Virtual Sampling | Price Range |

Techpacker | Yes | Real-time | No | $25–$50/user/month |

| CLO 3D | Partial | Team sharing | Yes | $70–$150/user/month |

| Lectra PLM | Yes | Enterprise | No | Custom enterprise pricing |

| Adobe AI + Plugins | No | Medium | No | $21/user/month + plugins |

5.2 Cloud vs. Desktop

·Cloud: Remote access, auto-backup, quick sharing, version history.

·Desktop: More robust CAD tools, offline work, custom scripting.

5.3 AI & Automation Perks

·Auto-grading: Generate full size runs in minutes.

·Error detection: Flags missing fields, mismatched units, or spec inconsistencies.

·Smart libraries: Reuse trim call-outs and wash recipes across collections.

6. How do you choose the right fashion tech pack designer for your brand?

Picking the wrong designer can be as costly as skipping a tech pack entirely. Evaluate portfolios, communication style, turnaround, pricing—and don’t forget to check for category expertise.

Dive Deeper

6.1 Key Selection Criteria

Criterion | What to Look For |

Category expertise | Past work with denim, dresses, stage costumes |

Portfolio clarity | Clear flat sketches, spec sheets, grading rules |

| Communication | Proactive questions, timely replies |

| Turnaround & capacity | Meets your launch schedule—ask for sample dates |

| Cost vs. ROI | Compare fee to sample cost savings |

6.2 Sourcing Channels

·Freelancer sites: Upwork, Fiverr (filter for garment-industry pros)

·Specialist agencies: Fashion tech consultancies, local studios

·Communities & referrals: Reddit's r/fashionindustry, LinkedIn groups

6.3 Interview Questions & Red Flags

·Ask: “Can you walk me through a recent tech pack clothing design you created for a similar style?”

·Red flag: Vagueness on tolerances or missing trim references; inability to share even an anonymized example.

FAQ'S

1.Do you really need a tech pack?

A tech pack is essential for precise manufacturing, reducing errors by 70% (AAFA data), but can be optional for simple prototypes if you maintain detailed spec sheets and direct factory

2.What is required in a tech pack?

A tech pack must include detailed garment construction diagrams, measurement specs, material sourcing guidelines, and ASTM tolerances (industry standard), with CAD files and grading rules being critical to prevent production delays and ensure consistency across production runs.

3.What is a tech pack designer?

A tech pack designer is a specialized professional who transforms creative designs into factory-ready blueprints, utilizing CAD software and ASTM standards to specify stitch types, material GSM, and tolerance thresholds, effectively bridging the gap between fashion concepts and bulk production while reducing spec misinterpretation by 50% (AAFA).

4.How much does it cost to get a tech pack made?

A tech pack costs 150−2000+ depending on garment complexity and designer expertise, with freelance specialists offering flat-rate pricing while overseas manufacturers provide budget options, though ASTM compliance validation often justifies higher quotes for production-ready accuracy

Conclusion

Contact DiZNEW today for a customized OEM/ODM tech pack design quote—whether you need just 30 jeans or bulk runs for music festivals, dresses for a runway show, or performance gear, our expert team and advanced PLM systems will bring your vision to life with zero guesswork.