How to Find Clothing Manufacturers | Fast & Reliable

- Share

- Issue Time

- Apr 18,2025

Summary

Discover proven strategies to find reliable clothing manufacturers fast. Learn how to source, vet, and partner with global apparel factories for your brand.

How to Find Any Clothing Manufacturing Company?

Finding the right clothing manufacturing partner can feel like searching for a needle in a haystack—especially when you’re juggling quality, cost, and speed. In today's global marketplace, pinpointing a factory that aligns with your vision requires knowing where to look, what to ask, and how to evaluate every option.

Featured snippet: To find any clothing manufacturing company, first nail down your specs—MOQ, style, certifications—then hunt online via search engines, B2B platforms, and industry directories. Vet factories with samples and audits, compare OEM vs ODM models, and use digital tools or agents to streamline the process. This guide gives you actionable tactics to find the perfect partner for your apparel line.

1. What Types of Clothing Manufacturers Exist?

Snippet: Clothing manufacturers include full‑service garment makers, basic cut‑and‑sew workshops, OEMs, and ODMs. Full‑service factories handle everything from design to finishing, while others focus only on assembly. Knowing these differences helps match factory capabilities with your needs.

Dive Deeper

1.1 Garment Manufacturer vs. Clothing Factory

·Garment Manufacturer: Manages design, pattern‑making, fabric sourcing, cutting, sewing, finishing, and quality control. Perfect if you want a one‑stop shop.

·Clothing Factory (Cut‑and‑Sew): Typically requires you to supply patterns and fabrics. Ideal for brands with in‑house design teams.

1.2 How to Find a Factory for Your Clothing Line

·Google Search: “garment factory + [your region]”

·Trade Shows: Events like Canton Fair (Guang Dong) and MAGIC (Las Vegas) let you meet reps and inspect samples in person.

·Referrals: Ask peers in LinkedIn groups like Apparel Sourcing Network.

1.3 OEM vs. ODM: What’s the Difference?

| Feature | OEM (Own Design) | ODM (Factory Design) |

Design Input | You supply tech packs & sketches | Factory provides templates & concepts |

MOQ | Often higher (500+ pcs) | Often lower (100–300 pcs) |

| IP Ownership | You own patterns & rights | Factory may retain design rights |

| Speed to Market | Slower (custom design) | Faster (pre‑made collections) |

| Cost Implication | Higher upfront design fees | Lower design costs, but limited edits |

1.4 Which Are the Best Clothing Manufacturers for Startups?

·Low MOQ Specialists: Seek factories offering MOQs as low as 30–50 pieces.

·Flexible Service Range: Factories that handle both small batches and scale up for big orders.

·Eco‑Friendly Processes: Waterless dyeing, organic fabrics, and certifications can set you apart.

2. How Do You Research and Find Clothing Manufacturers?

The best way to locate your dream garment factory is to combine astute internet research—think Google searches on Thomasnet or Maker's Row—with on-the-ground trips to trade exhibitions and neighborhood chambers.

Snippet: Use Google, industry directories, and trade shows to find clothing factories. Online platforms like Thomasnet and Maker’s Row help you shortlist. Offline referrals, chambers, and exhibitions add credibility and personal connection to your search.

Dive Deeper

2.1 Online Research Channels

①Search Engines: Try queries like “finding manufacturers for clothing line” + region.

②Industry Directories:

·Thomasnet (USA)

·Kompass (Global)

③B2B Marketplaces:

·Maker’s Row (USA‑focused, curated)

·Sewport (global capacity info)

·Alibaba (massive, but vet carefully)

2.2 Offline Research Strategies

·Trade Shows & Exhibitions: Inspect quality firsthand; build rapport.

·Local Chambers of Commerce: Access certified factory lists.

·Professional Referrals: Post detailed requests in Facebook groups like r/fashionstartup.

2.3 Focusing on the USA

| Resource | Coverage | Notes |

| Maker's Row | US factories | Hand‑vetted, startup‑friendly |

| Thomasnet | Industrial | Filter by capabilities & location |

| MAGIC Sourcing | Trade show | Seasonal, Las Vegas |

3.Where and Which Platforms Should You Use?

Snippet: Use Alibaba for cost efficiency, Reddit for grassroots insights, UK directories for European partners, and “near me” searches to find local workshops ready for small batches.

Dive Deeper

3.1 How to Find a Clothing Manufacturer on Alibaba

·Search Filters: Enable “Gold Supplier,” “Trade Assurance,” and “Verified.”

·Due Diligence: Request factory tour videos, ask for customer references, watch for stock‑photo traps.

3.2 How to Find a Clothing Brands Manufacturer on Reddit

·Participate in r/SmallBusiness and r/fashionstartup:

·Post your project details.

·Ask for vendor experiences and contact referrals.

·Be specific: share styles, MOQ, and budget to get targeted replies.

3.3 Clothing Manufacturers in the UK

·Directories:

·Made in Britain (accreditation list)

·The Manufacturer UK supplier database

·Benefits: Shorter shipping times, EU compliance, and “Made in UK” branding boost.

3.4 Clothing Manufacturers Near Me

| Search Query | Result Type | Benefit |

| “Clothing manufacturers near me” | Google Maps list | Quick tours, instant QA checks |

| “Textile clusters [your city]” | Local directories | Bulk supply proximity, faster turnaround |

4. Which Criteria Should You Use to Evaluate Potential Partners?

Snippet: Evaluate by MOQ, unit cost, lead time, payment terms, equipment, R&D capacity, and eco‑credentials. Ensure they can support both small (30 pcs) and large orders seamlessly.

Dive Deeper

| Criterion | Startup Needs | Enterprise Needs |

MOQ | 30–100 pcs | 1,000+ pcs |

| Unit Cost | $15–$25 per item | $5–$10 per item |

| Lead Time | 4–6 weeks | 8–12 weeks |

| Payment Terms | 30% deposit, balance | Negotiable, L/C |

Pro Tip: Negotiate a tiered pricing structure—unit cost drops as volume increases.

·Modern Tech: Laser cutters, digital pattern machines, automated sewing lines.

·R&D Labs: On‑site prototyping, wash labs, fit rooms.

Checklist: Before committing, ask to see an R&D capability list and sample room tour (even via video call).

4.3 Sustainability & Certifications

| Certification | Purpose | Approx. Cost/Time |

| ISO 9001 | Quality management | $2,000–$5,000 / 3–6 mo |

| OEKO‑TEX 100 | Harmful‐substance‐free | $500–$1,500 / 1–2 mo |

| GOTS | Organic textile standard | $3,000–$7,000 / 4–6 mo |

Data Point: Factories using waterless ozone washing cut water usage by up to 90%, appealing to eco‑conscious brands.

Snippet: Check ISO, OEKO‑TEX, and WRAP certificates, conduct on‑site or third‑party audits, and demand pre‑production samples (fabric, fit, wash) to confirm real‑world quality.

Dive Deeper

5.1 Key Certifications to Seek

·ISO 9001: Confirms quality management processes.

·OEKO‑TEX 100: Ensures no harmful chemicals.

·WRAP: Validates ethical labor practices.

5.2 Audits & Factory Visits

·In‑Person Tours: Inspect workflow, safety gear, and cleanliness.

·Third‑Party Inspections: SGS, Bureau Veritas can give unbiased compliance reports.

5.3 Sampling Process

·Fabric Swatch: Check hand‑feel, stretch, and weight.

·Proto Garment: Fit test on live models or dress forms.

·Wash Sample: Validate color fastness and distress patterns.

Snippet: OEM gives you total design control and unique IP. ODM offers faster launches with ready‑made templates. Choose OEM for brand‑distinct lines and ODM for quick-turn capsule collections.

Dive Deeper

6.1 OEM (Own Design Manufacturing)

·Pros: Full IP ownership, custom fits, unique detailing.

·Cons: Longer lead times (8–12 weeks), higher upfront design fees.

6.2 ODM (Original Design Manufacturing)

·Pros: Quick market entry (4–6 weeks), lower initial design costs, smaller MOQs (~100 pcs).

·Cons: Limited customization, potential design overlap with other clients.

6.3 Choosing the Right Model

·Emerging Brands: Go OEM if brand identity is core.

·Trend‑Driven Lines: Choose ODM to ride seasonal waves fast

6.4 Negotiating Contracts

·Include IP clauses for patterns and toolings.

·Set exclusivity windows to avoid factories selling your design to others.

·Define penalties for missed deadlines or quality issues.

Snippet: Beyond Alibaba, explore Maker’s Row, Sewport, Sourcify, and Facebook/Reddit communities for vetted listings, AI matching, and sourcing agents who handle POs, inspections, and logistics.

Dive Deeper

7.1 Online Directories Beyond Alibaba

| Platform | Specialty | Highlight |

| Maker's Row | US‑based factories | Curated, quality‑focused |

| Sewport | Global capacity data | Real‑time factory availability |

| Sourcify | Agent‑assisted | End‑to‑end sourcing & logistics |

7.2 Sourcing Agents & Networks

·Role: Negotiate pricing, manage audits, coordinate shipments.

·Fee Structure: Typically 5–10% of production cost but can cut your total spend by 15–20%.

7.3 Peer Communities & Apps

·Reddit: r/fashionstartup for unfiltered feedback.

·Fiber2Fashion App: Mobile scouting of hundreds of factories.

·LinkedIn Groups: “Apparel Sourcing Network,” “Fashion Industry Professionals.”

7.4 Future Trends: AI & Blockchain

·AI Matching: Platforms analyze your tech pack to suggest ideal factories.

·Blockchain Traceability: Provenance tracking for raw materials—key for sustainability claims.

Insider Tip: Sign up for trial versions of sourcing platforms to test their matching accuracy before committing.

1.What is the app that finds clothing manufacturers?

Top-rated apps like Alibaba.com, Jawsqtr, and Thomasnet connect fashion brands with global clothing manufacturers, offering verified supplier directories, RFQ tools, and quality control integrations to simplify sourcing - key features startups and established brands prioritize when vetting production partners.

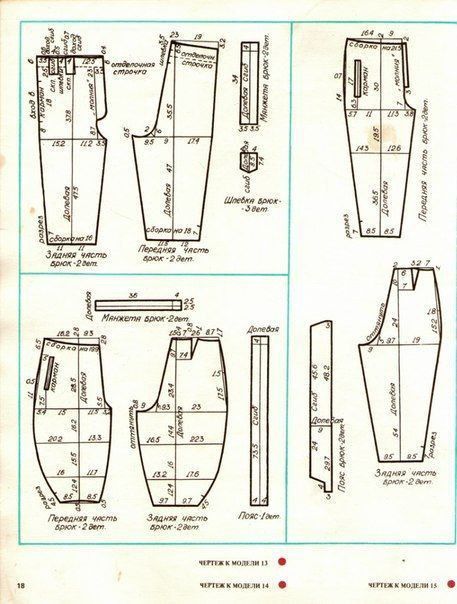

2.How do i send a clothing design to a manufacturer?

To send clothing designs to manufacturers, create digital tech packs with prototype specs, material lists, and CAD files using tools like Adobe Illustrator or Tukatech, then share via email/cloud with annotations for seamless production alignment – essential steps designers often overlook when preparing production-ready files.

3.How do i partner with a clothing manufacturer?

To partner with clothing manufacturers, negotiate MOQs (minimum order quantities), draft apparel production contracts with quality clauses, and request samples for evaluation before bulk orders – critical steps emerging brands often skip when onboarding ethical, scalable manufacturing partners.

4.How much does it cost to manufacture your own clothes?

Clothing manufacturing costs range from 5 − 5−50+ per unit based on fabric complexity, labor rates (overseas vs domestic production), and MOQs (minimums from 50-500 units), with hidden expenses like pattern grading, import duties, and quality control inspections often overlooked by first-time producers.

Conclusion

In a nutshell, finding the right clothing manufacturer comes down to knowing exactly what you need—MOQ, style, certifications—then combining focused online searches (Google, Thomasnet, Maker’s Row) with real‑world vetting (trade shows, referrals, chamber lists), comparing OEM vs ODM options, and using samples and audits to confirm quality; armed with these steps, you'll confidently zero in on a factory that matches your vision. Ready to skip the guesswork and get your next collection into production? Contact DiZNEW today for a tailored quote and one‑stop OEM/ODM service that brings your designs to life sustainably and seamlessly.

Discover our Custom Detachable Floral Cargo Jeans—crafted for comfort and style. Offering OEM/ODM and wholesale options for your brand!

Custom-printed flare jeans with bold abstract designs, combining bootcut style and artistic denim for a statement look

Custom mid rise wide leg jeans with black flared and baggy styles. Tailored designs for bulk orders and personalized fashion

Custom Patchwork Denim Jacket – OEM & ODM services for a unique, made-to-order distressed design. Perfect for wholesale opportunities!