How Blue Jeans Are Made: Step-by-Step Process & Techniques

- Share

- Issue Time

- May 24,2025

Summary

Discover how blue jeans are made—from raw denim to finished jeans. Learn the dyeing, stitching, and distressing techniques used in denim production

How Are Blue Jeans Made

Quick Answer: Cotton fibers become yarn, woven into denim, dyed indigo, cut and stitched into shape, then washed, distressed, and quality-checked. Each step blends tradition with eco-friendly tech and strict inspection, delivering durable style.

1. What Are Blue Jeans and How Were They Invented?

Snippet: Blue jeans started as 19th-century miner’s workwear, patented by Levi Strauss and Jacob Davis in 1873. Today, they’re a global fashion staple, revered for strength, comfort, and endless style tweaks.

Dive Deeper

1.1 Denim’s Origin Story

·“Serge de Nîmes” → “Denim”: 17th-century France wove sturdy twill for uniforms.

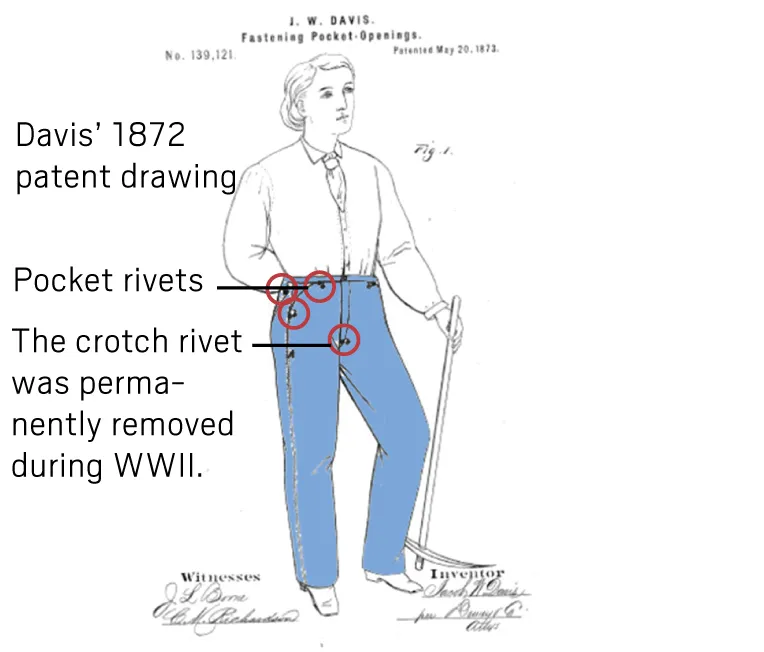

·Gold Rush Pivot: Strauss, a dry-goods merchant, teamed with tailor Davis to add copper rivets—jeans were born.

1.2 The “True Blue” Japanese Tradition

·Japan’s Kojima district still hand-dips yarn in natural indigo, achieving that coveted “fade from within.”

·Hand-Rope Dyeing Process

①Twist yarn into ropes

②Dip repeatedly in indigo

③Air-oxidize for deep, uneven hues

1.3 Cultural Evolution

| Era | Style Evolution | Iconic Moment |

1870s–1900s | Workwear with rivets | Miners, cowboys |

| 1950s–1960s | Rebel symbol (greasers, rock ‘n’ roll) | James Dean in Rebel Without a Cause |

| 1990s–2000s | Designer labels, skinny/bootcut craze | Runway appearances |

| 2010s–Today | Vintage selvedge, sustainable washes | Streetwear crossovers |

2. How Many Pairs of Blue Jeans Are Made in the World and Why Are They So Popular?

Snippet: Over 2 billion pairs of jeans roll off global production lines each year. Their secret sauce? Durability, versatility, and a cultural cachet that spans generations and continents.

Dive Deeper

2.1 Global Production by Region

| Region | Annual Output (Millions) | Market Share (%) |

| Asia-Pacific | 1,100 | 55 |

| Europe | 500 | 25 |

| Americas | 400 | 20 |

·Asia-Pacific Lead: China and India crank out most units, from budget basics to premium lines.

·Europe & Americas: Focus on mid-to-high end, with “Made in USA” or “Italian-made” as selling points.

2.2 Why We Can’t Quit Jeans

·Rock-Solid Durability: Denim’s diagonal weave resists tears and abrasion.

·Style Chameleon: Dress them up with a blazer or down with sneakers.

·Cultural Touchstone: From Woodstock to Coachella, jeans mirror our values.

3. What Raw Materials Are Used and What Makes Jeans Blue?

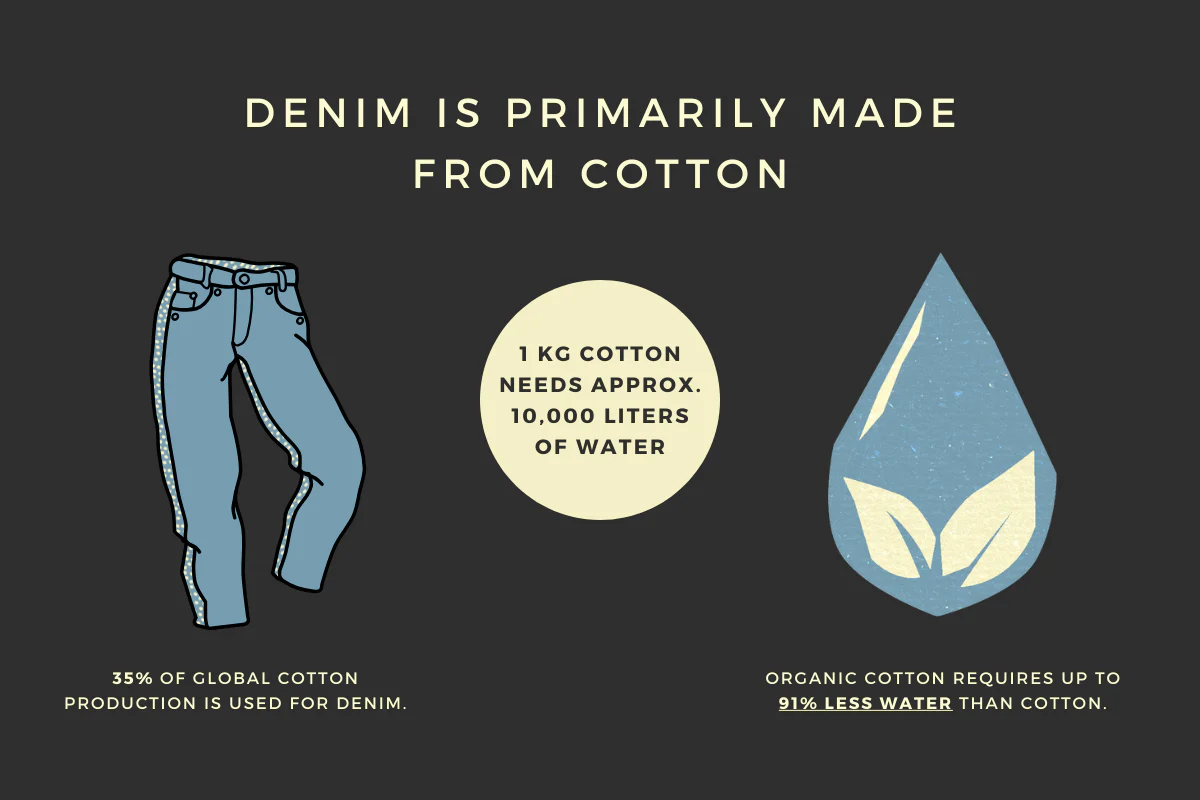

Snippet: Blue jeans start with cotton—often long-staple for strength—and get their blue coat from indigo, which bonds to the fiber’s surface, fading uniquely over time.

Dive Deeper

3.1 Cotton Types & Blends

| Fiber Type | Feel & Strength | Typical Use |

| Short-Staple | Coarser, more pills | Entry-level denim |

| Long-Staple | Smooth, durable | Premium/high-end jeans |

| Cotton-Elastane | Stretchy, comfy | Skinny/stretch fits |

·Why Elastane? 1–2% adds flexibility, keeping shape without bagging out.

3.2 Indigo Dye Science

·Vat Dyeing: Indigo is insoluble; it’s reduced to a soluble “leuco” form, so yarn soaks it up. Once exposed to air, it reverts to blue, sitting on the surface.

·Natural vs. Synthetic: Plant-based indigo is eco-friendlier but costlier; synthetic dominates large runs.

4. How Is Cotton Transformed into Denim and What Is the Denim Manufacturing Process?

Snippet: Cotton is cleaned, carded, spun into yarn, then woven in a twill pattern. Shuttle looms yield selvedge edges; projectile looms maximize speed.

Dive Deeper

4.1 Spinning & Yarn Prep

·Carding: Removes impurities and aligns fibers.

·Combing (for premium denim): Takes out short fibers for a smoother yarn.

4.2 Weaving on Looms

| Loom Type | Speed | Output Quality | Typical Use |

| Shuttle | 30–60 rpm | Selvedge edge, strong | Artisan/designer jeans |

| Projectile | 200–400 rpm | Uniform, high output | Mass-market denim |

Tip: “Selvedge” edges appear as clean lines on the fabric’s side—collectors sniff them out like vintage wine connoisseurs.

5. Which Dyeing Methods Are Employed to Color Jeans Indigo?

Snippet: Yarn can be rope dyed (deep, uneven fade) or sheet dyed (even color). Hybrid and eco-dyes are emerging to cut water and chemicals.

Dive Deeper

5.1 Rope vs. Sheet Dyeing

·Rope Dyeing: Yarn ropes dip 10–20 times—each dip deepens shade and enhances fade character.

·Sheet Dyeing: Large fabric sheets pass through vats—faster, more uniform, ideal for big batches.

5.2 Next-Gen Dye Tech

| Technique | Water Savings | Key Benefit |

| Foam Dyeing | Up to 65% | Precise application, less waste |

| Ozone Fading | ~50% | No harsh chemicals |

| Laser Finishing | ~90% | Pinpoint distress without water |

6. How Are Blue Jeans Made Step by Step (Cutting, Sewing, Finishing)?

Snippet: After dyeing, denim panels get markers planned, cut, sewn with heavy threads, riveted, and finished—then washed, distressed, and rigor-tested.

Dive Deeper

6.1 Marker Planning & Cutting

·Digital Markers: CAD software nests patterns to minimize waste—up to 15% fabric saved.

·Cutting Tables: Automated blades slice hundreds of layers in minutes.

6.2 Sewing & Hardware

·Stitch Types:

·Lock Stitch: Strong, invisible seam.

·Chain Stitch: Elastic, decorative—often on back pockets.

·Riveting & Button Setting: Machines set hardware at high speed; skilled operators inspect placement.·

6.3 Washing, Distressing & Quality Control

·Washing Options:

·Stone Wash: Rough stones tumble to soften and fade.

·Enzyme Wash: Cellulase enzymes eat loose fibers for a gentler fade.

·Distressing: From hand-sanding to sandblasting (controversial for worker safety).

·Final QC: Every pair undergoes visual checks (stitch integrity, color consistency, hardware snugness).

7. How Are Light Blue Jeans Made and How Are Jeans Made with Water?

Snippet: Light blue shades come from bleaching or enzyme actions. Water-saving tech like foam dyeing, ozone, and lasers can cut water use by up to 90%.

Dive Deeper

7.1 Creating Light Blue Hues

| Method | Process | Pros & Cons |

| Chlorine Bleach | Harsh chemical soak | Quick but eco-unfriendly |

| Oxygen Bleach | Peroxide-based, gentler | Slower but greener |

| Enzyme Wash | Targets fiber fuzz | Softer feel, moderate fade |

·Foam Dyeing: Dye suspended in foam—applied directly, slashing bath size.

·Ozone Treatment: Ozone gas breaks down indigo—no water needed.

·Laser Distressing: Laser beams etch patterns, no water or chemicals.

8. Are Any Blue Jeans Made in the USA and How Do OEM/ODM Services Support Custom Manufacturing?

Snippet: Yes—Levi’s “Made in USA” lines and boutique selvedge producers. DiZNEW’s OEM/ODM gives you full design, prototyping, and low-MOQ (30 pcs) or large-order runs.

Dive Deeper

8.1 USA-Made Denim Brands

·Levi’s Vintage Clothing: Premium selvedge, domestic mills.

·Artisan Labels: Small workshops hand-finish every stitch, selling at $200+ per pair.

| Step | Activity | Timeframe |

1. Design Brief | Gather specs, moodboards | 1–2 weeks |

2. Sampling | Produce 1–3 prototypes | 2–3 weeks |

3. Fit Testing | Adjust patterns, trims | 1 week |

4. Small-Batch Run | MOQ 30 pcs | 4 weeks |

| 5. Scaling Up | Thousands+ pieces | 4–6 weeks |

| 6. QC & Shipping | Inspections, global logistics | 1–2 weeks |

·Why It Rocks: Start small, tweak designs, then ramp up—no wasted inventory or surprises.

1.What is the process of making blue jeans?

The process of making blue jeans involves cotton spinning, indigo dyeing (for the iconic blue shade), weaving denim fabric, cutting and sewing panels, applying distressing techniques (like sandblasting or laser treatments), and finishing touches (washing, adding rivets), with modern brands increasingly adopting sustainable practices like waterless dyeing and organic materials.

2.Are jeans still dyed with indigo?

Yes, most jeans are still dyed with indigo (typically synthetic indigo for durability), though modern brands increasingly use eco-friendly alternatives like plant-based dyes, closed-loop systems, or waterless dyeing to reduce environmental impact while maintaining the iconic blue hue.

3.How do they make denim blue?

Denim gets its iconic blue color primarily through indigo dyeing, where yarns are repeatedly dipped in indigo dye (traditionally plant-based, now mostly synthetic) to create a ring-dye effect that fades uniquely over time, with modern innovations like sulfur dyes, eco-friendly techniques (laser fading, water recycling), and natural fermentation indigo gaining traction for sustainability.

4.ls denim 100% cotton?

Denim was traditionally 100% cotton, but modern variations often blend elastane (1-3%) for stretch, incorporate recycled polyester for sustainability, or use Tencel blends for softness, while premium raw selvedge denim remains 100% cotton for durability and authentic fading.

Conclusion

Whether you’re drawn to the rich heritage of Japanese rope-dye or intrigued by cutting-edge laser finishes that save millions of gallons of water, there’s a denim process tailored for your brand’s vision. And with DiZNEW’s OEM/ODM expertise—starting at just 30-piece minimums and scaling to large runs—you get personal design support, thorough sampling, and rigorous quality control every step of the way.

Ready to transform your denim dreams into reality? Contact DiZNEW today for a custom quote, and let’s create your next iconic pair of blue jeans—crafted uniquely for you.