Find Reliable Jeans Suppliers for Retail Biz | Expert Tips

- Share

- Issue Time

- Apr 23,2025

Summary

Learn proven strategies to identify trustworthy jeans suppliers for your retail business. Compare quality, pricing, and wholesale partnerships with confidence.

How to find a reliable jeans supplier for my retail business?

Denim isn't just fabric—it's a way people express themselves. Whether you’re stocking classic five-pocket styles or the latest distressed skinny jeans, partnering with the right supplier can make or break your line.

Finding a reliable jeans supplier starts by clarifying your brand’s needs—styles, budgets, and sustainability targets—then tapping online platforms, local networks, and USA-specific directories. Vet candidates through targeted questions, audits, and sample testing. Finally, negotiate MOQs, pricing, and OEM/ODM terms to secure a long-term partnership that delivers quality denim on time and on budget.

Imagine launching your next denim collection without sleepless nights worrying about delays or quality issues—picture your customers’ excitement when they pull on that perfect-fit pair, knowing it was crafted just for them. Stick around, and I'll walk you step by step through the whole process.

1. What are your specific sourcing requirements and objectives?

Clarify your target market, design complexity, budget range, quality benchmarks, and sustainability goals before you even start looking—this roadmap ensures you attract suppliers who can actually deliver what you need.

From fiber to garment: precise supply chain is the core of quality

The process selection in each link directly affects the cost structure and brand premium space

Laser cutting | Water-saving dyeing | Intelligent quality control

Dive Deeper

1.1 Pinpointing Your Target Market

Streetwear vs. Premium vs. Workwear

Streetwear brands often lean into bold washes, slim fits, and playful distressing.

Premium labels focus on selvedge denim, artisanal details, and higher price tags.

Age & Lifestyle Demographics

Teens and Gen Z might chase ultra-skinny, high-rise fits.

Professionals over 30 often prefer straight or relaxed cuts with subtle detailing.

1.2 Balancing Quality and Cost

Denim Weight & Durability

| Denim Weight (oz) | Feel & Use Case | Approx. Cost per Yard (USD) |

8–10 | Lightweight, summer wear | $5–$7 |

| 11–13 | Everyday wear, midweight | $7–$9 |

| 14–16 | Heavy-duty, workwear | $9–$12 |

Hardware & Trims

Custom rivets and engraved buttons boost brand identity but add $0.10–$0.30 per piece.

Branded leather patches can cost $1–$3 each depending on material.

1.3 Design Complexity & Innovation

Wash Techniques

Stone wash uses pumice stones to create vintage fades.

Laser distressing offers eco-friendly, precise patterns—look for suppliers with laser machines to reduce water use by up to 80%.

Embroidery & Appliqué

Intricate embroidery can take 5–15 minutes per piece on automated machines; factor in $2–$5 extra per pair.

1.4 Sustainability & Ethics

Water-Saving Technologies

Foam dyeing cuts water consumption by 50–90%.

Ozone and laser finishing can reduce water use by 70–90% compared to conventional methods.

Key Certifications

| Certification | Focus Area | Why It Matters |

| GOTS | Organic fiber & processing | Ensures 100% organic cotton and eco-friendly dyes |

| Oeko‑Tex | Harmful substances | Guarantees textiles are free from toxins |

| Bluesign | Environmental footprint | Verifies sustainable chemical and resource use |

2. Which online platforms can help you find a reliable jeans supplier for my retail business online?

Use B2B marketplaces like Alibaba, Global Sources, and specialized directories to shortlist suppliers—check verified badges, read reviews, and request samples right from your desk.

𝗝𝗲𝗮𝗻𝘀 𝗦𝘂𝗽𝗽𝗹𝘆 𝗘𝘅𝗽𝗲𝗿𝘁 | 𝗗𝗿𝗶𝘃𝗶𝗻𝗴 𝗙𝗮𝘀𝗵𝗶𝗼𝗻 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆

√ 15 years of focus on denim manufacturing technology

√ 300+ factory direct style library

√ OEKO-TEX® certified environmentally friendly denim

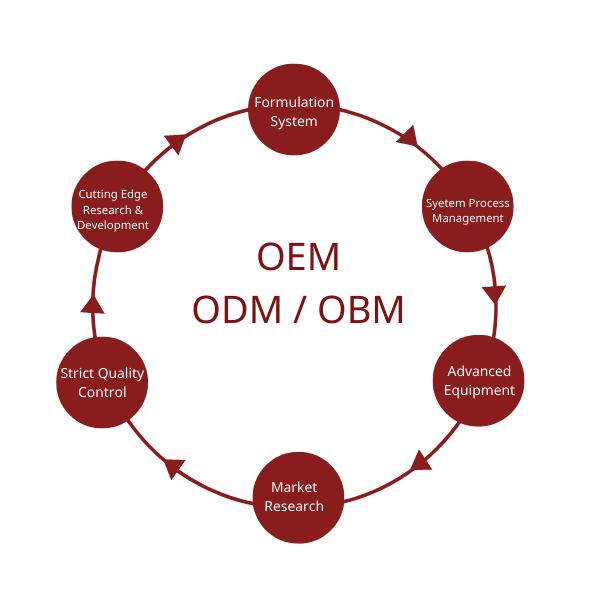

√ Support ODM/OEM flexible customization

Supply chain solutions trusted by global brands

Dive Deeper

2.1 B2B Marketplace Breakdown

| Platform | Highlights | Verification Level | Typical Fees |

| Alibaba | Trade Assurance, RFQ tool, sample ordering | On-site factory audits | Free basic; membership fees for Gold Suppliers |

| Global Sources | Sourcing fairs, Gold Suppliers directory | Third-party inspections | Subscription plans starting at $1,000/year |

| Made‑in‑China | Category labs, buyer protection | Random inspections | Free basic; advanced features paid |

2.2 Industry-Specific Directories

ThomasNet: Great for U.S. and North American suppliers; filter by “Apparel Manufacturing” and “Denim.”

MakersRow: Curated U.S. factories—perfect for small runs and “Made in USA” branding.

2.3 LinkedIn & Social Media Sourcing

Search terms like “denim manufacturer” + city name (e.g., “denim manufacturer Los Angeles”).

Check employee profiles for production managers; send a quick InMail to introduce your project.

Join groups such as “Denim & Jeans Professionals” to ask peers for firsthand recommendations.

2.4 Vetting Online Suppliers

Profile Completeness: Look for detailed company descriptions, factory photos, and case studies.

Customer Reviews: Prioritize suppliers with multiple 4–5 star reviews mentioning on-time delivery and consistent quality.

Escrow Services: Use platform escrow (e.g., Alibaba’s Trade Assurance) to protect your payments until goods arrive as promised.

3. How to find a reliable jeans supplier for my retail business near my location?

Local trade shows, manufacturing clusters, and word-of-mouth referrals are your secret weapons—seeing a factory in person gives you peace of mind and faster turnarounds.

Dive Deeper

Denim Première Vision (Paris, Shanghai): A hotspot for new fabric innovations and mill connections.

Regional Textile Fairs: Smaller, local expos often feature nearby cut‑and‑sew shops and wash houses.

3.2 Touring Manufacturing Hubs

Los Angeles Denim District: Over 200 factories within a few square miles—ideal for rapid sampling and prototyping.

Guangdong Province, China: Massive capacity but beware of brokers; aim to meet the actual factory owners.

3.3 Leveraging Peer Referrals

Ask non-competing local brands about their go‑to suppliers.

Reach out to your city’s garment manufacturer association or chamber of commerce for vetted member lists.

3.4 Pros & Cons of Nearby Suppliers

| Advantage | Drawback |

| Lower shipping costs | Smaller factories may have limited capacity |

| Easier site visits | Potentially higher labor rates |

| Faster sample turnarounds | Less access to specialty denim mills |

4.How to find a reliable jeans supplier in the USA for my retail business?

“Made in USA” carries weight—use U.S. sourcing platforms, state associations, and domestic shows to find compliant, eco-friendly denim makers who cut lead times and protect your IP.

Dive Deeper

4.1 “Made in USA” Sourcing Tools

MakersRow: Browse U.S. factories by service (denim, wash, embroidery).

ThomasNet: Filter by “Apparel” and “Textile” to locate domestic mills and finishers.

4.2 State-Level Industry Hubs

North Carolina: Historic mills with mid-volume runs and eco‑finishing options.

Los Angeles, CA: Fast-turnaround cut‑and‑sew shops perfect for micro-batches.

Texas: Emerging facilities focusing on water-saving technologies.

4.3 Domestic Trade Shows

Sourcing at MAGIC (Las Vegas): One of the largest U.S. apparel sourcing events—meet 3,000+ exhibitors.

Denim PDX (Portland): Highlights sustainable denim innovations from West Coast mills.

4.4 Weighing Pros & Cons

| Pros | Cons |

| Strong IP protection | Higher labor and operating costs |

| Shorter shipping times | Limited volume discounts |

| Easier communication and time zones | Fewer specialty mills for unique washes |

5. What questions should you ask potential jeans suppliers to assess their capabilities?

Cover production capacity, lead times, sample policies, material sourcing, subcontracting, certifications, MOQs, and client references to make sure they tick every box.

Dive Deeper

5.1 Production Capacity & Lead Time

Monthly Output: Can they handle 1,000 pairs per month or just 200?

Lead Time Breakdown:

Sampling: 2–4 weeks

Bulk Production: 4–8 weeks

Shipping: 1–3 weeks

5.2 Sample Policy Details

Costs: Are wash trials included or extra?

Revisions: How many free tweaks before they charge?

5.3 Fabric & Trim Sourcing

Denim Origins:

Japanese denim often costs 20–30% more but is prized for texture.

Turkish mills offer a balance of cost and quality.

Trim Suppliers: In-house hardware vs. third-party—impact consistency.

5.4 Compliance & Certifications

Social Audits: SMETA, BSCI, WRAP—ask for recent audit reports.

Environmental: ISO 14001, Oeko‑Tex, GOTS—request scanned certificates.

Tiered Pricing Example:

| MOQ (pcs) | Unit Price (USD) |

30 | $25.00 |

| 100 | $18.00 |

| 300 | $12.50 |

| 500 | $10.00 |

Hidden Fees: Setup, packaging, artwork.

5.6 Client References & Case Studies

Request contact info for two similar-size brands.

Review any written case studies on their site—especially on-time delivery stats.

6. How can you evaluate a supplier’s credibility, quality, and consistency?

Use on-site or remote audits, sample testing, certificate verification, KPI tracking, and tech tools like QR codes or ERP dashboards to keep tabs on quality from start to finish.

Integration of craftsmanship and technological quality inspection

On-site audits ensure sewing accuracy (8-12 stitches/inch), and the laboratory strictly tests color fastness and tear resistance (≥25N).

Each box is embedded with a QR code for traceability, and the ERP system tracks the entire production chain. The defect rate is ≤2% before delivery.

Dive Deeper

6.1 Audit Types

On-Site Audit: Best for deep dives—inspect machinery, worker conditions, and workflow.

Remote Audit: Video tours can flag red flags early; cheaper and faster.

6.2 Sample Inspection & Lab Testing

Fit & Finish: Look at stitch density (8–12 stitches per inch is ideal), seam strength, and hardware function.

Lab Tests:

| Test | Standard | Why It Matters |

| Colorfastness (AATCC 61) | Grade 4–5 | Ensures minimal fading during wash |

| Shrinkage (AATCC 135) | ≤ 3% | Guarantees consistent sizing post-wash |

| Tear Strength (ASTM D2261) | ≥ 25 N | Measures fabric durability |

Cross‑check certificate numbers on issuing bodies’ websites.

Conduct unannounced visits if possible to verify real practices.

6.4 Ongoing Quality Monitoring

KPIs: On-time delivery ≥ 95%; defect rate ≤ 2%.

Statistical Sampling: Inspect 5–10% of each batch, focusing on high-risk SKUs.

6.5 Tech-Enabled Traceability

QR Codes: Attach codes to each carton to trace origin and production details.

ERP Dashboards: Real-time updates on material arrivals, production status, and shipment schedules.

7. What is the typical minimum order quantity (MOQ) for jeans suppliers and how does it impact pricing?

MOQs range from 30 to 300+ pieces per style. Smaller batches let you test new designs but cost more per unit; bulk runs cut costs but tie up inventory.

Dive Deeper

7.1 MOQ Tiers & Use Cases

Micro-Batch (30–50 pcs): Great for market testing; expect 15–30% higher unit costs.

Standard Batch (100–300 pcs): Balanced approach—good for core styles.

Bulk Orders (500+ pcs): Best for established bestsellers; lowest unit price but higher invent

| MOQ (pcs) | Unit Price (USD) | Total Cost (USD) |

30 | $25 | $750 |

| 100 | $18 | $1,800 |

| 300 | $12.5 | $3,750 |

| 500 | $10 | $5,000 |

7.3 Strategies to Reduce MOQ

SKU Grouping: Combine multiple colorways or sizes in one production run.

Shared Orders: Partner with fellow retailers or boutiques to pool volumes.

7.4 Cash Flow & Inventory Impact

Overstock Risks: Unsold jeans eat up storage space and capital.

Just-In-Time Ordering: Smaller, frequent orders keep cash free and shelves fresh.

7.5 OEM/ODM Flexibility

Some suppliers will lower MOQ in exchange for design or pattern-making fees—worth it if you’re after unique fits or washes.

8. How do you negotiate terms, secure OEM/ODM services and build long-term partnerships?

Negotiate clear tech packs, payment structures, lead times, and IP protections, then nurture the relationship with regular communication, joint R&D, and performance reviews.

Dive Deeper

8.1 Crafting a Bulletproof Tech Pack

Specs Sheet: Include fabric weight, stitch count, hardware details, and tolerance levels.

Visual References: Flat sketches, 3D mockups, wash photos, and video samples.

8.2 Payment Terms & Delivery

Deposit Structure: Common split is 30% upfront, 70% upon shipping.

Payment Methods: T/T is common; letters of credit (LC) reduce risk but add fees.

Incoterms:

| Term | Responsibility |

| FOB | Buyer arranges shipping, takes risk at port |

| CIF | Seller covers cost, insurance, freight to port |

| DDP | Seller handles all costs to destination door |

8.3 Safeguarding Your Designs

NDAs: Sign before sharing any tech packs or design files.

Design Registration: File for design patents or trademarks in key markets.

8.4 Volume Discounts & Co-Marketing

Negotiate tiered pricing: 5% off at 200 pcs, 10% off at 500 pcs.

Ask suppliers for marketing support—like co-branded lookbooks or launch events.

8.5 Communication Cadence

Weekly Calls: Quick video check-ins keep everyone on the same page.

Shared Dashboards: Grant suppliers access to your project management tool for real-time updates.

Host virtual workshops with your supplier’s R&D team to brainstorm washes, fits, and sustainable finishes.

Share trend forecasts and sales data to co-create your next bestsellers.

8.7 Performance Reviews & Continuous Improvement

Set quarterly KPIs: on-time rate, defect rate, cost variance, innovation contributions.

1.Which quality of jeans is best?

The best-quality jeans combine long-staple cotton (e.g., Zimbabwean/Turkish), selvedge denim (shuttle-loomed for density), reinforced stitching (copper rivets, chain-stitched hems), and ethical craftsmanship—exemplified by Japanese artisans (Pure Blue Japan), heritage revivals (Levi’s LVC), or eco-conscious innovators (Nudie Jeans) for durability, fade character, and timeless appeal.

2.How do i find a good pair of jeans?

To find a great pair of jeans, prioritize fit (slim/straight/wide-leg for your body type), fabric (100% cotton for durability, 2% elastane for stretch), and brand ethos (heritage like Levi’s, sustainable like Nudie, or selvedge artisans like Momotaro)—test comfort by squatting, check stitching quality, and invest in versatile washes (indigo/black) for long-term wear.

Conclusion

Ready to bring your denim dreams to life? Contact DiZNEW today for a custom quote, and let our OEM/ODM experts guide you from sketch to shelf—no stress, no surprises, just perfectly crafted jeans your customers will love.

Purchase custom multi-pocket patchwork jeans by DiZNEW. Unique distressed denim with utility pockets, tailored for high-fashion streetwear.

Men's baggy ripped jeans featuring silver studs and an embroidered design, offering a bold streetwear vibe with a distressed look.

Vintage washed wide-leg jeans with frayed patchwork and distressed fashion details—crafted for boutique and luxury designers.

Bold cutout denim pants with layered, sculptural detailing, offering a futuristic and edgy streetwear appeal. Designed for high-fashion brands and trendsetters.