Find Denim Jacket Suppliers | Reliable Sourcing Tips

- Share

- Issue Time

- Apr 23,2025

Summary

Discover trusted denim jacket suppliers & manufacturers. Get bulk pricing, quality assurance, and fast shipping for your business needs.

How to find a denim jacket supplier?

Finding the perfect denim jacket supplier can feel downright impossible—so many options, so many horror stories of bad quality, missed deadlines, or hidden fees. Here's the gist: pick partners who nail capacity, quality checks, pricing, MOQs, and sustainability; tap both online marketplaces and in-person trade shows; weigh domestic speed versus overseas scale; and always sample before you commit. Stick with me, and you'll hear how Laura, a tiny indie label owner, went from “no clue” to “sold-out” by blending Zoom factory tours with Google searches—and how you can too.

1. What are the key criteria to select a dependable denim jacket supplier?

Quick answer: Check their production capacity, QC steps, pricing & MOQs, sustainability credentials, lead times, and how fast they respond to your emails.

Dive Deeper

①Production Capacity & Lead Times

·Why it matters: You don’t want a factory that “can do 5,000 units a month” until they miss holiday surges and leave you with empty shelves.

·Ask specifics:

·Peak vs. off-peak output

·Number of shifts per day

·Backup machines on site

②Quality-Control Systems

·In-line inspection: Fabrics checked before cutting.

·End-of-line: Samples from each batch are tested.

·Random audits: Surprise checks reduce defect rates.

·Pro tip: Look for ISO, SGS, or Intertek audit reports—those badges mean they’ve opened their books.

③Pricing & Minimum Order Quantities (MOQs)

·Why MOQs matter: Testing a new style with 30 pieces is gold for small brands; buying 500 to hit price breaks is perfect for big launches.

·Table: Typical MOQ vs. Pricing

| MOQ Range | Approx. Unit Price | Notes |

30–100 units | $28–$38 | Small-batch, boutique vibe |

| 101–300 | $22–$28 | Good balance of cost and volume |

| 301–600 | $18–$22 | Bulk discounts start here |

| 600+ | $14–$18 | Large factories, lowest per-unit cost |

·Hidden fees to watch for:

·Air-freight on small orders

·Design setup or CAD fees

·Packaging customization

④Sustainability Credentials

·Certifications to ask:

·OEKO-TEX Standard 100 (no harmful chemicals)

·GOTS (organic cotton chain-of-custody)

·Bluesign (resource-efficient processes)

·Water use data: Modern laser or ozone finishing can cut water usage by up to 70% vs. traditional stone washes.

·Greenwashing alert: Ask for raw data—liters of water per dozen jackets, energy source mix (e.g., solar vs. fossil fuel).

⑤Communication & Responsiveness

·Lightning-fast replies today predict smooth problem-solving tomorrow.

·Language skills matter: Misunderstanding “zipper color” can add weeks and $$$.

·Cultural fit: A supplier who “speaks your brand's language” reduces creative friction.

2. How to find a denim jacket supplier online and “find denim” that fits your brand?

Quick answer: Hit B2B platforms like Alibaba, Global Sources, Maker's Row; use targeted keywords; vet badges, reviews, and sample requests; and back it up with Zoom factory tours.

Dive Deeper

①Major Online Marketplaces

·Pros: Millions of listings, super-competitive prices.

·Cons: Vetting takes work—look for “Gold Supplier,” “Onsite Check,” and trade assurance.

·Pros: Higher verification standards, good for larger volumes.

·Cons: Less bargain hunting than Alibaba.

Maker's Row (U.S.)

·Pros: Domestic focus, transparent pricing, lower MOQs (30–200).

·Cons: Higher unit costs.

②Platform Comparison Table

| Platform | Verified Suppliers | MOQ Range | Best For |

| Alibaba | Medium | 30–500+ | Global price searching |

| Global Sources | High | 100–1000+ | Quality-focused sourcing |

| Maker's Row | High | 30–200 | Domestic, small runs |

③Keyword Strategies

Exact matches:

Broad searches:

·“find denim”

·“denim fabric mill”

·“denim OEM/ODM”

④Evaluating Supplier Profiles

1.Sample requests—get swatches, then full panels

2.Customer reviews—spot patterns (fast shipping vs. poor stitching)

3.Response times—same-day replies are a huge plus

⑤Social Media & Forums

·Facebook groups: “Fashion Startups,” “Clothing Manufacturer Network”

·Reddit: r/fashiondesign—real designers sharing real pain points

⑥Online Audit & Verification Tools

·Zoom factory tours—ask for live video

·Third-party inspection—companies like QIMA or AsiaInspection

3. How to find a denim jacket supplier in the USA?

Quick answer: Use ThomasNet, MFG, Maker’s Row; hit trade shows like MAGIC; leverage state clusters in North Carolina or California; and enjoy faster turnaround with easier compliance.

Dive Deeper

①Benefits of Domestic Sourcing

·Faster delivery: 2–5 days vs. 4–8 weeks

·Regulatory compliance: U.S. labor & environmental laws

·Easier disputes: U.S. courts, clear contracts

·Downside: Labor costs can be 30–50% higher than Asia

②Key U.S. Platforms

·ThomasNet: Filter for “denim,” “outerwear,” “garment manufacturing.”

·Maker's Row: Transparent quotes, small batch friendly.

③Trade Shows & Events

·MAGIC (Las Vegas): Largest apparel show, denim pavilion included.

·Denim PV (Pomona, CA): Dedicated denim sourcing, finishing tech demo

④State Clusters

| State | Strength | Example Suppliers |

| North Carolina | Historic textile mills, spinning | Mill A, Dye House B |

| California (LA) | Innovative finishes, boutique runs | Factory X, Studio Y |

| Texas | Growing garment hubs, cost-effective | Facility Z |

⑤Quality Inspection & IP Protection

·On-site visits—easy if factory’s local

·Legal recourse—clear U.S. contracts

By the way, the 135th Canton Fair will open in Guangzhou from May 1st to 5th. We will bring our innovative achievements to booth M01 in Hall 2.1 and sincerely invite you to explore business opportunities together!---We are a custom men's denim factory--DiZNEW

4. How to find a factory or denim manufacturer for your clothing line?

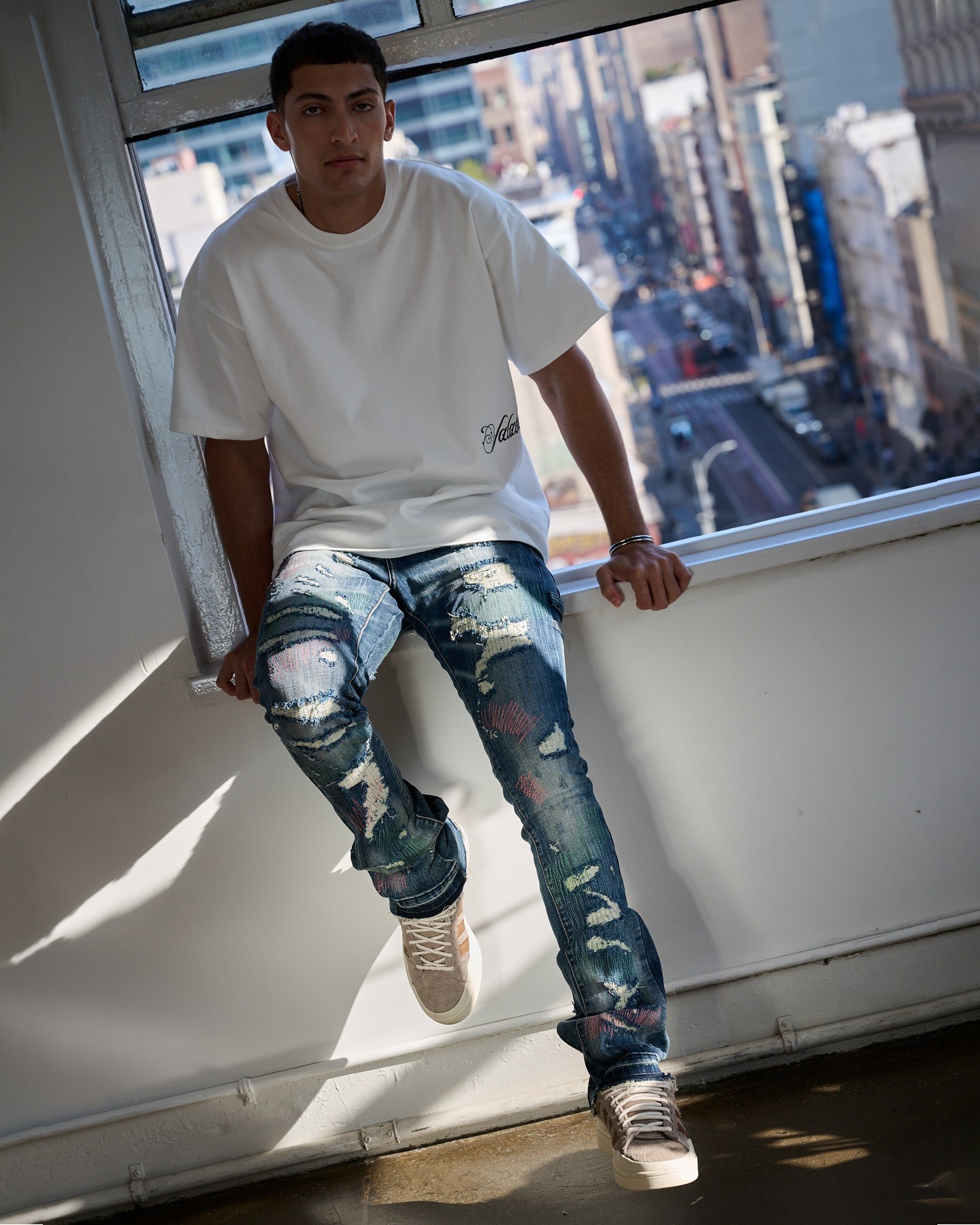

Aligning vision with precision: A collaborative tech pack review ensures every stitch count, fabric GSM, and hardware spec meets your brand’s standards—turning sketches into flawless denim realities.

Quick answer: Build detailed tech packs, hunt factories via networks and directories, vet compliance records, and insist on audits or video tours before committing.

Dive Deeper

①Spec Sheets & Tech Packs

·Details to include:

·Stitch counts (e.g., 9 SPI)

·Seam types (e.g., felled, overlocked)

·Hardware specs (button size, zipper brand)

·Fabric GSM (e.g., 12 oz denim)

·Why: Vague specs = variable outcomes

②Industry Networks & Referrals

·Associations: AAFA, Sourcing Journal community

·Peer recommendations: Ask about “fail stories” to avoid common pitfalls

③Certifications & Compliance

·WRAP, SEDEX, Fair Wear Foundation—look for social & environmental audits

·Red flags: Factories refusing audit results or non-transparent about labor practices

④Factory Audits & Virtual Tours

·In-person audit: Best but costly (~$1,000+)

·Video tours: Cost-effective—request 360° walkthroughs

⑤Sampling & Negotiation

·Sample budgets: 2–3% of total order value

·Negotiation tips:

·Bundle design and packaging fees

·Lock in prices with multi-season contracts

⑥Long-Term Partnerships

·Factories prefer predictable orders—consider annual volume commitments for better rates.

5. How to evaluate samples and choose a good denim jacket?

Quick answer: Test fabric weight & feel, stitch integrity, hardware quality, fit trials, wash & colorfastness—and iterate with real users before buying big.

Dive Deeper

①Fabric Analysis

Weight & handfeel:

·10–12 oz: Classic jacket feel

·12–14 oz: Premium, stiff initially but shapes with wear

·Stretch vs. rigid: Stretch (1–2% elastane) for comfort; rigid for authenticity

②Construction Quality

·Stitch-per-inch (SPI): 8–10 SPI = sturdy seams

·Seam types:

·Felled seams = durable, no fray

·Overlock seams = cheaper, less durable

③Hardware & Trims

| Component | Brand/Type | Durability Test | Notes |

| Zippers | YKK | 20,000 open/close | Industry gold standard |

| Buttons & Rivets | Custom | Salt spray 48h | Check corrosion |

④Fit & Sizing

·Wear tests: Staff wear samples for 1–2 days, note mobility

·Size grading: Ensure consistency from S–XL

⑤Wash & Finish Tests

·Colorfastness: 5 washes rub tests

·Finish durability: 10,000 flex cycles for stones and lasers

⑥Consumer Feedback

·Pilot release: 20–50 units to ambassadors

·Surveys: Simple Google Forms for fit & comfort feedback

6.How do MOQ, pricing models, and OEM/ODM services impact your supplier choice?

Quick answer: Low MOQs give flexibility but higher per-unit costs; high MOQs unlock savings but risk overstock; OEM offers full design control, ODM accelerates time-to-market.

Dive Deeper

①MOQ Trade-Offs

Low MOQ (30–100): Test new markets, control cash flow

High MOQ (500+): Lower unit cost, tight margins

·Per-piece: Straightforward (unit × qty)

·Tiered: Discounts at thresholds (e.g., 1–100, 101–300, 301–600)

·Total-cost table

| Qty Ordered | Unit Price | Total Cost |

| 50 | $32 | $1,600 |

| 200 | $24 | $4,800 |

| 500 | $18 | $9,000 |

③OEM vs. ODM

·OEM: You send tech packs; factory produces exactly your spec.

·ODM: Factory’s in-house designs you tweak—faster but less unique.

④Hidden Costs to Budget

·Sample fees

·CAD/setup costs ($100–$300)

·Packaging design and mockups

⑤Inventory Strategies

·JIT (Just-In-Time): Low stock risk, demands precise planning

·Bulk buys: Cheaper per unit, higher holding costs

7.How do you protect your design IP and ensure sustainable production?

Guarding the planet alongside profits: Transparent audits track every drop saved and watt renewed, ensuring your brand’s legacy is both legally protected and sustainably crafted.

Quick answer: Lock in NDAs, detailed contracts with IP clauses, register trademarks/patents, and verify eco-certifications and real water/energy savings.

Dive Deeper

①Legal Protections

·NDAs: Cover sketches, tech packs, digital files

·Contracts: Include penalties for IP leaks, late delivery, defects

②Registering IP

·Trademarks: Logo, brand name, label design

·Design patents: Unique features (e.g., convertible hood)

③Supplier Audits

·IP audit trails: Who accessed what files, when

·Quality audits: Verify claimed eco-processes (water recycling logs)

④Eco-Certifications

·OEKO-TEX: Safe textiles, no banned chemicals

·GOTS: Certified organic fibers and fair labor practices

·Water savings data: Demand liters per jacket—and compare

⑤Energy & Waste Management

·Laser finishing slashes water use by 50–80% vs. stone wash

·Solar/power mix: Ask percentage of renewable energy on-site

⑥Continuous Improvement

Annual reviews: Re-evaluate supplier on cost, quality, sustainability

Workshops: Co-develop greener finishes and recycling programs

1.How to find a good denim jacket?

To find a good denim jacket, prioritize fit (slim/regular/oversized for your body type), mid-weight cotton (12-14oz) for durability, reinforced stitching at stress points, and versatile washes (medium blue/black); check reputable brands like Levi's Vintage or Wrangler Retro for quality construction, and consider jacket length relative to your torso for optimal layering.

2.Where do denim jackets come from?

Denim jackets originated in the 19th-century American West as durable workwear, popularized by Levi Strauss's patented riveted 'Type I' jacket (1890), evolving from railroad worker uniforms into cultural symbols through 1950s motorcycle culture and 1980s Hollywood films, with heritage brands like Levi's, Lee, and Carhartt preserving this legacy through raw selvedge denim and modern reinterpretations.

3.How to find quality denim?

To identify quality denim, look for heavyweight fabrics (12-14 oz+) from reputable mills like China's DiZNEW or Italy's Candiani, choose raw/unwashed selvedges that are sewn tightly and evenly with reinforced bar stitching, prioritize pre-shrunk treatments to minimize shrinkage, and seek out heritage brands known for their broken twill weaves and long-staple cotton for durability.

4.Can a 50 year old wear a denim jacket?

Absolutely – style a denim jacket at 50+ with age-appropriate tailoring: opt for dark washes, mid-weight denim (10-12oz), and cropped/tailored cuts from heritage brands like Levi's Commuter or Lee Modern Series, paired with elevated basics (cashmere sweaters, structured trousers) and silver hardware for sophistication, proving timeless Americana transcends generations when balanced with modern minimalist aesthetics.

Conclusion

Finding a reliable wholesale denim jacket supplier can feel overwhelming—but it doesn't have to be. By focusing on what really matters—quality, low MOQ, design flexibility, and a proven track record—you’ll set your brand apart in a crowded market.

At DiZNEW, we don't just make denim jackets—we help build fashion businesses. Whether you're just starting out or scaling up, our team is ready to support your next collection. Reach out today to customize your first wholesale denim order with us.