Find Clothing Manufacturers | Reliable Suppliers

- Share

- Issue Time

- Apr 22,2025

Summary

Discover trusted clothing manufacturers & suppliers for custom apparel production. Compare pricing, MOQs, and fast turnaround times for your brand.

Where can I find clothing manufacturers?

Finding an outstanding clothing manufacturer sets the fate of your brand since it leads to satisfied customers through high-quality products and swift deliveries yet selecting the wrong manufacturer results in schedule delays and dissatisfied customers.

Summary (Featured Snippet):

You can find reliable clothing manufacturers through trade shows, B2B platforms (Alibaba, Maker's Row), regional hubs (Hong Kong, Guangdong, USA), and local agents—balancing MOQs, certifications, and sustainability credentials to fit your budget and brand DNA.

1. What methods can I use to find clothing manufacturers?

Snippet: You can locate clothing manufacturers via trade shows, referrals, online directories, social media groups, and B2B marketplaces—each offering different insights on MOQs, lead times, and quality standards.

Dive Deeper

①Trade Shows & Exhibitions

·Why go? Face‑to‑face chats let you feel fabric, inspect stitch samples, and haggle MOQs on the spot.

②Top picks:

·MAGIC (Las Vegas): 85,000+ attendees, 4,000+ exhibitors.

·Première Vision (Paris): High‑fashion focus, premium mills.

·Canton Fair (Guangzhou): China’s largest, covering home textiles to machinery.

For example, China's Canton Fair runs from April 15th to May 5th within Guangzhou city which signifies the largest trade show in the nation. The Canton Fair stands as a significant attraction point particularly for apparel buyers because it offers an unparalleled amount of ready-to-wear and sportswear together with fabrics trims and accessories. The fair consists of three stages that allow buyers to interact with numerous suppliers during face-to-face meetings while assessing quality immediately and conducting live negotiations of production terms. The place to focus on large-scale fashion procurement exists at this location.

③Referrals & Network Outreach

·Power of word‑of‑mouth: A factory vouching for you can unlock better pricing and faster samples.

·Where to ask: LinkedIn groups (e.g., “Fashion Startup Club”), alumni networks, even your local sewing guild.

④Social Media & Niche Forums

·Facebook groups such as “Shopify Apparel Entrepreneurs” often have honest, unfiltered feedback.

·Reddit's r/fashionbiz: real talk about nightmare factories to avoid.

⑤Local Sourcing Agents

·What they do: Audit factories, negotiate, oversee production, and handle logistics.

·Cost: Typically 5–10% of your production value—worth it if you’re new to a region.

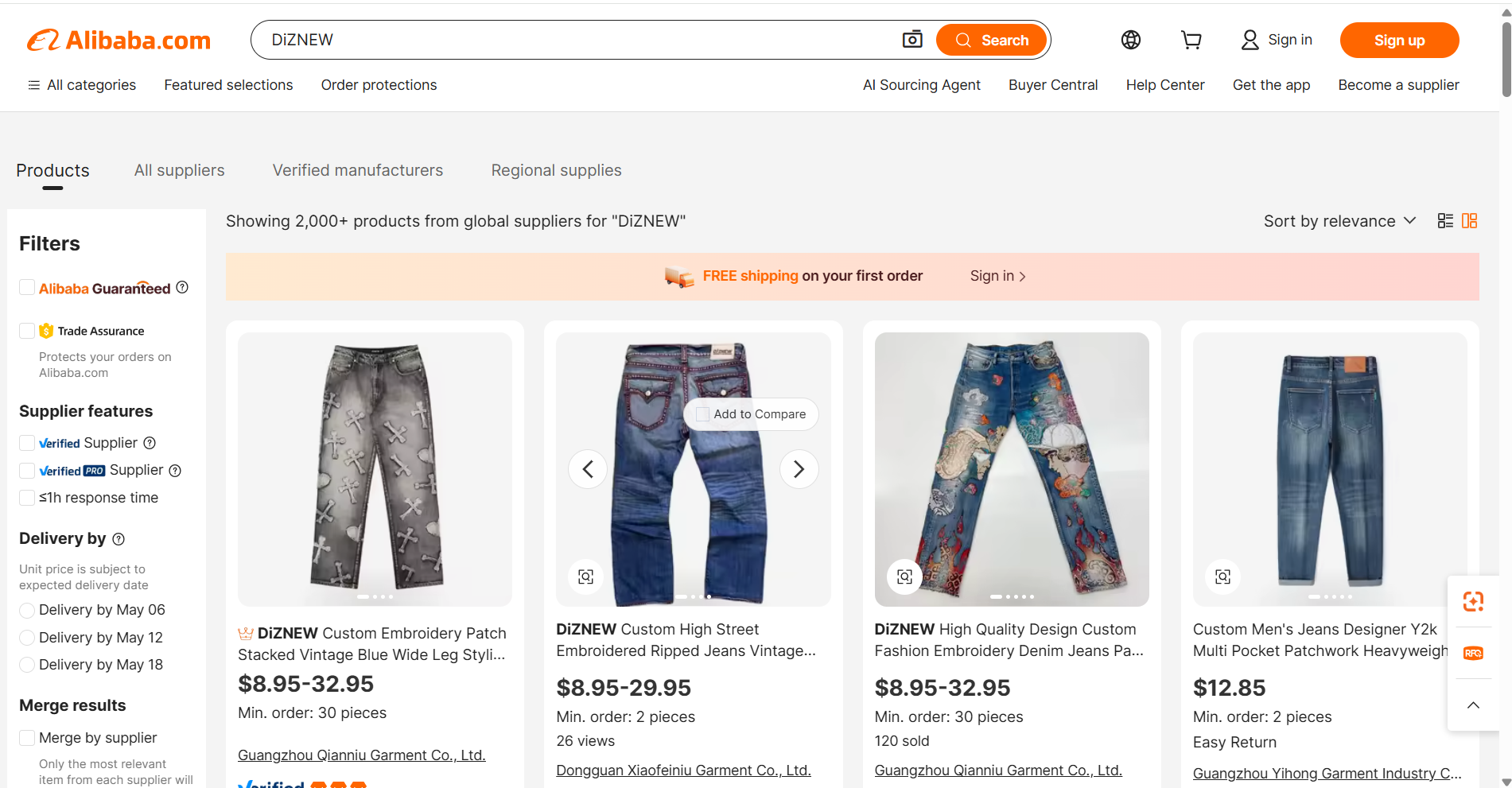

2. Which online platforms are most effective for sourcing clothing manufacturers?

Snippet: Top platforms include Alibaba for huge volume, Global Sources for vetted partners, Maker’s Row for US factories, and Sewport for small‑batch/sustainable production.

| Platform | Strengths | Drawbacks | MOQ Range |

Alibaba | Massive database; trade assurance; reviews | Quality varies; vetting needed | 100–5,000 |

Global Sources | Pre‑screened; show events; innovation focus | Higher MOQs; mid‑to‑large orders | 300–2,000 |

Maker’s Row | US factories; transparent costs | Higher labor costs; limited variety | 50–500 |

| Sewport | Small‑batch; eco‑friendly options | Smaller selection; niche focus | 30–300 |

| ThomasNet | Detailed specs; NA focus | Industrial rather than fashion | N/A (varies) |

Key Tips:

1.Vet via samples: Always order one or two prototypes before committing.

2.Check reviews: Look for response rate, on‑time delivery, and long‑term partnerships.

3.Use trade assurance: Platforms like Alibaba offer buyer protection for payments.

3. Where can I find clothing manufacturers in key global regions?

Snippet: Major hubs are:

·Guangdong, China:The province of Guangdong functions as an international center for clothing manufacturing because it provides focused fabric markets and efficient production sites along with advanced logistics networks for brand manufacturers seeking comprehensive solutions. The cities of Guangzhou and Dongguan together with Zhongshan operate efficient factories which manage big order deliveries and e-commerce flexibility while providing smooth operations from design creation to shipping completion.

·USA: A clothing manufacturer located in the United States enables quick and efficient communication alongside speedy deliveries especially when dealing with short-run small batch production. Boutique factories and custom workshops can be found in multiple locations throughout New York and Los Angeles region.

·Bangladesh/Vietnam: Listed among the leading fast fashion and basic product production hubs are these countries because of their incredibly low labor costs. After meeting European and American brand factory inspection standards more and more factories have begun to enhance their technological capabilities and product quality evolution. Such businesses fit well with brands focused on price rather than volume.

Dive Deeper

| Region | MOQ (pcs) | Lead Time | Strengths | Weaknesses |

| Guangdong, China | 100–1,000 | 3–6 weeks | Vertical mills; cheap scale | Longer shipping |

| USA | 50–500 | 2–4 weeks | IP protection; fast iterations | Higher cost |

| Bangladesh / Vietnam | 500–5,000 | 6–12 weeks | Lowest labor cost | QC can be uneven |

4. What distinguishes high‑quality and top‑rated denim producers?

Snippet: High-end denim uses long‑staple cotton (Supima, Zimbabwe), advanced looms, precision chain‑stitch hems, and holds certifications like OEKO‑TEX® and BCI.

Dive Deeper

Quality Factor | What to Look For | Impact on Jeans |

Raw Cotton | Supima (USA), Zimbabwe long‑staple | Softer hand; better drape |

Loom Tech | Air‑jet, rapier looms | Cleaner weave; less waste |

| Stitching | Chain‑stitch hems; reinforced bartacks | Durability; classic look |

| Finishing | Ozone, enzyme wash, laser distressing | Eco‑friendly; consistent |

| Certifications | OEKO‑TEX®, BCI, GOTS | Chemical safety; traceable |

·Raw Material: Brands paying 10–15% more for Supima cotton get denim that ages gracefully and resists pilling.

·Weaving: Air‑jet looms can spin at 1,000+ meters/minute, cutting production time by 20%.

·Construction: Chain‑stitch gives that coveted “whisker” pattern on knees after washes.

·Sustainability: Factories using ozone treatments can slash water usage by 70% compared to traditional stone‑washing.

5.What sustainable practices should you expect from modern denim factories?

Snippet: Look for waterless dyeing (AirDye), recycled yarns (TENCEL™), ZDHC chemical controls, and wastewater treatment—so your jeans look good without costing the planet.

Dive Deeper

| Practice | Technique / Standard | Environmental Benefit |

Waterless Finishing | AirDye™, foam dyeing | Cuts water use by ~90% |

Recycled Fibers | Recycled polyester, TENCEL™ | Reduces virgin input |

| Chemical Management | ZDHC MRSL compliance | Limits toxic discharge |

| Energy Efficiency | Solar panels; heat recovery systems | Lowers carbon footprint |

| Certifications | GOTS, Bluesign®, SAC Higg Index | Independent validation |

·AirDye®: Uses pressurized air to embed dyes—no water at all.

·Recycled Yarns: Brands can claim “up to 50% recycled content,” reducing landfill waste.

·Chemical Transparency: ZDHC MRSL-compliant factories report each chemical used, ensuring safety for workers and end‑users.

6. How do OEM and ODM services streamline the design‑to‑production process?

OEM means you provide the design and the factory implements it; ODM means you modify the existing template and it is easier to quickly produce samples.

One-stop service allows seamless connection of the entire process from pattern making, production to shipment, doubling the design efficiency and protecting your originality.

Snippet: OEM means you own the design; ODM means you tweak an existing template—both let you consolidate suppliers, speed development, and protect your IP with a single point of contact.

Dive Deeper

OEM (Original Equipment Manufacturer)

ODM (Original Design Manufacturer)

·Factory provides: Base patterns, fabric choices, hardware options.

·You do: Branding tweaks—labels, trims, colorway edits.

·Best for: Quick market tests, capsule collections.

Integrated Services

·One‑Stop Shops: Offer CAD grading, pattern making, prototyping, bulk runs, and even drop‑shipping.

·Workflow Tools: Cloud PLMs like Techpacker or CLO 3D to keep everyone on the same page.

IP Protection

·Ask for: NDA templates, design-registration support, secure file storage.

·Tip: Stagger shipments if you fear knock‑offs—send cutting tickets separate from actual fabric.

7.How can you assess a manufacturer’s equipment, quality control, and large‑order capabilities?

Snippet: Audit for modern machinery (Juki sewing lines), ISO 9001 QC protocols, in‑house labs (tensile, colorfastness), and documented scalability processes—from 100 to 100,000 units.

Dive Deeper

①Factory Audits & Tours

·Checklist: Equipment age ≤ 5 years, maintenance logs, workflow layout that minimizes handling.

②Quality Management Systems

Look for: ISO 9001 certificates, SOP documentation, Statistical Process Control (SPC) charts.

③Sample & Pilot Runs

·Why it matters: Confirms wash stability, seam strength, and hardware durability before bulk commitment.

⑤In‑House Testing Labs

Key tests:

·Tensile strength (ISO 13934)

·Colorfastness (AATCC 61)

·Pilling resistance (ASTM D4970)

⑥Scalability & Contingency Plans

Discuss: Backup sewing lines, staffing surge capacity, alternate

1.Where is the best place to manufacture clothing?

Your selection of ideal clothing manufacturing locations should match your business requirements because China delivers cost-effective large-scale production but Vietnam offers skilled workforce along with lower tariffs while Bangladesh specializes in affordable textile production.

2.How do i create my own clothing brand?

You need at least five steps to develop a clothing brand starting with market research to create your niche along with supplier selection (Alibaba or Maker’s Row) and establishing brand identity through Canva design and securing proper legal protection such as trademarks and LLCs before implementing your e-commerce platform through Shopify or Etsy while focusing on sustainable practices combined with fashionable social media content to make your brand noticeable to customers.

3.How much does it cost for a clothing manufacturer?

Supply costs for garment manufacturers range from $3-15 for production in China to $4-12 for manufacturers in Bangladesh, while Vietnamese suppliers charge between $8-20 per piece. The initial order quantity (100-500+ pieces), fabric complexity, and certifications required all affect pricing, but choosing a factory with clear, reasonable prices, and factoring in freight and costs is key.

4.How do i send a clothing design to a manufacturer?

Provide the entire design package consisting of tech packs. Advise them about your request for a production quotation and interest in understanding minimum order numbers alongside lead times, sampling processes and costs.

Conclusion

The process of selecting a clothing OEM factory is complex. Knowing your production needs and the search channels and evaluation criteria will help you find the right business partner faster. Choosing an OEM factory is crucial for emerging fashion brands, music festivals, and established clothing brands that are growing their business.

You can start looking for a clothing OEM factory through the Alibaba platform or posters posted in Los Angeles. The key is to find a factory that can provide design assistance while meeting your requirements for flexibility and quality standards.

With low minimum order quantities (starting at 30 pieces), in-house design and development, sustainable material sourcing, and a streamlined OEM/ODM process, DiZNEW provides a one-stop denim production solution that meets modern needs.

Please share with us your design, brand vision or plan to develop high-waist party wear, stage wear, social media wear, and outdoor wear. The production operations of excellent factories not only create clothing products, but also help brands develop. DiZNEW's main product is denim products, which help brands develop.

Custom distressed wide-leg jeans with heavy ripping and vintage wash for a bold streetwear look.

Silver foil cargo jeans with a distressed wash and multi-pocket design, perfect for high-street fashion.

Edgy black denim jeans with buckle straps, metal eyelets, and a wide-leg fit for a bold gothic punk streetwear look.

Elevate your workwear with our custom special denim jeans. Built for durability and a rugged industrial look.