Denim Jackets vs. Jeans: Fabric & Style Differences

- Share

- Issue Time

- Apr 21,2025

Summary

Discover if denim jackets use the same fabric as jeans. Learn key differences in material, style, and durability for fashion choices.

Are denim jackets made from jeans?

Denim jackets are everywhere—from music festivals to coffee shops—and yet many folks still wonder, “Are they literally cut from old jeans?” The quick answer: no, brands use fresh rolls of denim fabric, not deconstructed pants, to craft jackets. This ensures consistent quality, even washes, and spot‑on sizing. Imagine you’re backstage at a rock show, your denim jacket perfectly broken‑in yet structurally sound—that’s the magic of purpose‑made denim. Stick around, and I’ll take you behind the seams.

A denim jacket is an upper‑body garment made from sturdy twill‑woven cotton called denim. With characteristic button closures, yokes, and pockets, it’s cut differently from jeans for an ideal jacket fit.

Dive Deeper

①What’s the difference between a denim jacket and a jean jacket?

·Denim jacket highlights the construction—front and back panels, tailored yokes, classic trucker silhouette.

·Jean jacket is just another name born from matching your jeans; it doesn’t change how it's made, but history lovers might prefer “jean jacket” for nostalgia.

③When were denim jackets most popular?

Denim jackets boomed in the 1960s–’70s counterculture, punked out in the ’80s, and now back as streetwear staples in the 2010s–’20s with influencers and celebs leading the charge.

Key milestones in denim jacket history

| Year | Milestone |

1880 | Levi's patents first riveted work jacket |

1913 | Lee rolls out its Type I work jacket |

| 1962 | Levi's Type III “Trucker Jacket” hits stores |

| 1980s | Punk, metal, and rock scenes adopt customized styles |

| 2010s | High‑fashion designers remix the trucker silhouette |

2.Are denim jackets made from jeans or from the same denim fabric?

Denim jackets aren’t upcycled from worn jeans; both items begin as new denim bolts. Jackets need full‑width fabric for panel cuts, consistent indigo coverage, and precise wash treatments.

Dive Deeper

①Myth‑busting on Reddit

·"Are denim jackets made from jeans?"Reddit threads confirm factories cut from fresh rolls—recycling entire pant pieces would cause strange color shifts and mismatched grain.

·"Jean Jacket Nope"discussions debunk DIY upcycling myths: yes, you can patch old jeans, but true boutique and mass‑market jackets use yardage.

②Recycling vs. upcycling

·Recycling: Post‑consumer jeans are shredded, re‑spun into lower‑grade yarn—good for insulation or blends, less so for premium denim jackets.

·Upcycling: Artisans repurpose jean panels into patchwork jackets. Unique, yes. Scalable? Not unless you’re fine with wildly varied sizes and finishes.

Critical take

While Instagram loves the DIY vibe, large brands rely on fresh denim for uniform fades, durable seams, and predictable cost—all vital for meeting customer expectations and price points.

Denim fabric is rope or slasher dyed, woven, sanforized to lock in size, and enzyme‑ or stone‑washed to set hand and remove impurities—ensuring stable, wearable yardage for jacket patterns.

Dive Deeper

①Rope dyeing vs. slasher dyeing

·Rope dyeing: Yarn bundles pass repeatedly through indigo vats; yields deep, uneven fades prized by aficionados.

·Slasher dyeing: Continuous fabric dyeing; faster, cheaper, with uniform coverage—ideal for entry‑level lines.

②Sanforization and pre‑washing

·Sanforization: Mechanical stretching prevents garments from shrinking more than 1% after wash.

·Enzyme wash: Softens fibers, loosens surface indigo, and gives a gentle, lived‑in look without stones.

Fabric weight and usage

| Fabric Weight (oz/yd²) | Typical Use | Feel & Performance |

| 8–10 | Spring/Summer jackets | Lightweight, breathable |

| 11–13 | Year‑round wear | Balanced warmth & drape |

| 14–16 | Fall/Winter outerwear | Rugged, extra insulation |

Environmental impact

Conventional denim processing can use 3,000+ liters of water per jacket. Innovations cut that by up to 90% via ozone, laser, and foam technologies—big wins for eco‑minds.

4.Which stitching and finishing techniques are key in denim jacket production?

Felled seams, contrast top‑stitching, bartacks at stress points, and finishes like stone‑wash or laser distressing define quality, durability, and style in every denim jacket.

Dive Deeper

①Seam types and strength

·Flat‑felled seams: Encapsulate raw edges, preventing fraying—standard on side and sleeve seams.

·Chain stitching: Common at hems; gives that signature “whip‑stitched” look and slight stretch.

②Top‑stitching and hardware

·Contrast thread: Orange, gold, or charcoal highlight panel lines.

·Buttons & rivets: Heavy‑duty metal ensures pockets stay put—even under pressure.

Finishing processes

| Finish Technique | Effect | Pros & Cons |

| Stone‑wash | Soft hand, vintage look | Water‑heavy; risk of fabric damage |

| Enzyme wash | Subtle fade, eco‑friendlier | Gentler on fiber; longer processing time |

| Laser distressing | Precise whiskers & fades | Low water; high equipment cost |

Critical perspective

Brands must weigh aesthetic trends against environmental and worker safety concerns—stone‑washing might look rad but can harm textile workers without proper safeguards.

Absolutely. Eco‑denim uses foam dyeing, laser finishing, recycled cotton blends, and post‑consumer recycling—pushing the industry toward a circular model.

Dive Deeper

①Water‑saving dye & wash tech

·Ozone fading: Uses oxidized ozone in sealed chambers; simulates wear in minutes with minimal water.

·Foam dyeing: Dyestuff carried in foam instead of liquid baths; cuts effluent by ~70%.

②Recycled and organic fibers

| Fiber Type | Sustainability Benefit | Common Applications |

| Recycled cotton | Diverts waste, reduces virgin fiber demand | Insulation blends, lower‑weight denim |

| Organic cotton (BCI‑cert.) | Pesticide‑free, regulated water use | Premium, transparent origin pieces |

| TENCEL™ lyocell blends | Biodegradable, closed‑loop solvent process | Soft hand, lightweight jackets |

Upcycling case study

A boutique label in Amsterdam transformed 1,000 lbs of post‑industrial denim into 250 one‑off jackets—each unique, each carrying its own story, but at a $300–$500 retail price.

Trade‑offs and consumer education

While eco‑processes cost 10–30% more, clear storytelling—“saved 50,000 liters of water”—helps customers see the value and justify premium prices.

OEM/ODM partners manage every step—design, sampling, wash trials, quality checks—offering low MOQs (30+ pieces) and rapid turnaround, so brands launch without massive upfront risk.

Dive Deeper

Step 1: Design consult & tech packTitle

·Mood boards: Collate inspirations—vintage Levis, punk detailing, modern matte black hardware.

·Tech packs: Detailed specs (stitch count, pocket placement, button size) ensure zero miscommunication.

Step 2: Sampling & wash trials

| Round | Purpose | Timeline |

| 1 | Fit and basic construction review | 1–2 weeks |

| 2 | Wash and finish trials | 1 week |

| 3 | Final tweaks before bulk production | 3–5 days |

Step 3: Bulk production & QC

·Dedicated lines for small batches maintain consistent stitch quality and finishing.

·Inline and end‑line inspections catch defects early—less waste, fewer returns.

Spotlight example

A streetwear upstart ordered 50 black denim jackets with custom laser‑etched back panels. From first sketch to shipping took just eight weeks, fueling a sold‑out pre‑order in days.

Critical advice

Always verify your partner’s certifications (ISO, OEKO‑TEX), sample track record, and MOQ flexibility. A low MOQ partner (30–50 pcs) lets you test markets without massive capital lockup.

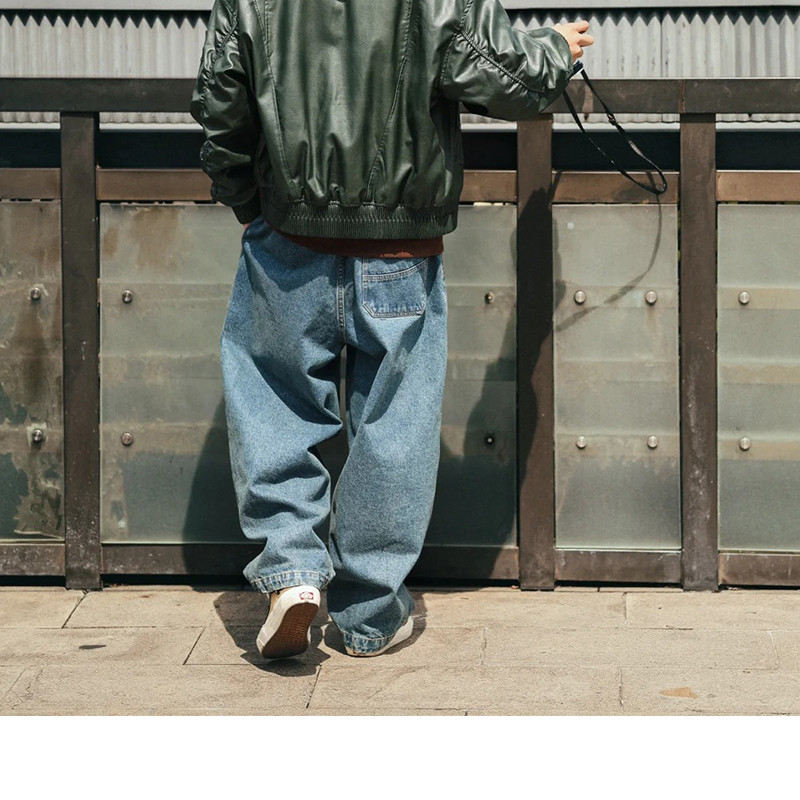

Denim jackets layer for winter warmth, anchor smart‑casual outfits, and shine at concerts, parties, and outdoor adventures—available in classic blue, black, men's and women's fits.

Dive Deeper

①Are denim jackets good for winter?

·Layering tip: wear over a fleece hoodie or flannel shirt.

·Opt for 14–16 oz denim or insulated linings; consider sherpa‑lined collars for extra coziness.

②Is a denim jacket formal?

·Traditionally casual, but pair a dark‑wash jacket with chinos, a button‑down, and Chelsea boots for smart‑casual flair.

③How many denim jackets should I own?

| Capsule Collection | Number of Jackets | Examples |

| Essential | 2 | One mid‑weight blue trucker, one black |

| Seasonal | 3-4 | Add a heavyweight winter jacket, a light spring shacket |

| Trend & Niche | 5+ | Cropped cuts, oversized fits, eco‑denim |

④Are jean jackets still popular or out of fashion?

Denim jackets never truly go out of style. Social media, runway shows, and celebrity endorsements keep them fresh—from Travis Scott’s oversized looks to Zendaya’s cropped silhouettes.

Critical reflection

Your lifestyle dictates selection: a daily commuter might love a water‑repellent finish; a festival‑goer may prioritize bold distressing and patchwork. Don’t chase every fad—invest in pieces you’ll wear for seasons to come.

1.What is a denim jacket made of?

A classic denim jacket is primarily made of durable cotton twill fabric, typically featuring 100% cotton for traditional styles or blended with stretch materials like elastane/spandex (1-2%) for modern comfort, with key components including indigo-dyed warp yarns, white filling threads, and reinforced stitching at stress points like pockets and seams.

2.Are jean jackets denim?

Yes, 'jean jackets' (commonly spelled 'jeans jackets') are made of denim—a sturdy cotton twill fabric woven with indigo-dyed warp yarns and white filling threads, often blended with polyester or elastane for modern flexibility, making them durable yet adaptable to casual or layered styles.

3.What do you call a jacket made of jeans?

A jacket made of jeans fabric is called a denim jacket (or jean jacket), crafted from durable cotton twill—often 100% cotton or blended with elastane for stretch—featuring signature details like rivet-reinforced pockets, triple stitching, and a classic shank button closure, popularized by Levi’s 19th-century workwear designs and now a staple in casual or vintage-inspired fashion.

4.What is real denim made of?

Real denim is traditionally crafted from 100% cotton yarns dyed with natural indigo, woven in a twill weave (2×1 or 3×1 patterns) for diagonal ridges, and reinforced with selvage edges on vintage shuttle looms—modern variations may blend polyester or elastane for stretch, but authentic denim prioritizes raw, unwashed cotton for durability and fade character.

Conclusion

Denim jackets aren’t made from old jeans—they’re crafted from fresh denim designed for structure, style, and durability. From classic truckers to trend-forward designs, they remain a timeless wardrobe staple for all seasons.