DIY Denim Jeans Marker Guide | Step-by-Step Tutorial

- Share

- Issue Time

- May 23,2025

Summary

Learn step-by-step methods to create efficient denim jeans markers. Boost manufacturing precision, save fabric, and streamline production with expert tips.

How to make marker for denim jeans manufacturing?

Featured Snippet: A marker is a layout plan that nests all jean pattern pieces on fabric to maximize usage and minimize waste. Top factories hit 92–96% efficiency, slashing costs and water pollution.

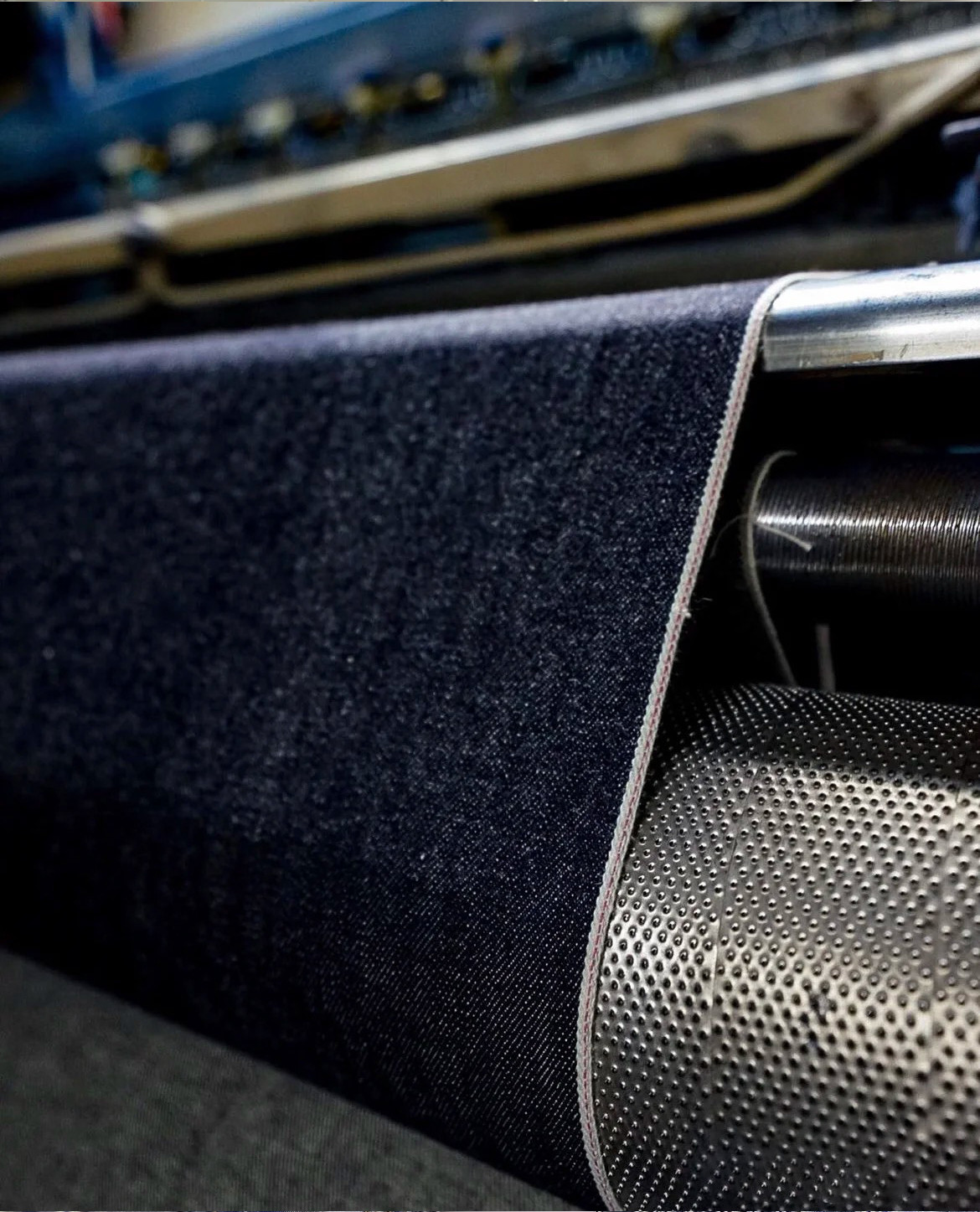

1. What Is Marker Making in Denim Jeans Production?

Dive Deeper

1.1 Fashion vs. Garment Industry

·Fashion Houses: Often hand-draft markers for one-offs or limited runs. Think couture denim: each marker a bespoke puzzle.

·Mass Production: Factories run dozens of orders daily—markers are CAD-generated to ensure repeatable precision.

1.2 Unique Challenges with Denim

·Selvedge Grain: Must align the edge so the self-finished seams look sharp.

·Stretch Denim: Knits behave differently—layouts need spacing to account for snap-back.

1.3 From Sketch to Marker

·Pattern Prep: Designer sends DXF or paper patterns.

·Fabric Survey: Note width (typically 58″–60″ for denim), repeat patterns, defect zones.

·Marker Assembly: Use software (e.g., Gerber, Lectra) or manual plotting to fit pieces together like Tetris.

2. Is Marker Efficiency Important for Sustainable Denim Manufacturing?

Featured Snippet: Marker efficiency = (pattern area ÷ fabric area) × 100. Higher efficiency means fewer scraps, cheaper costs, and less water/energy per jean.

Dive Deeper

2.1 Calculating Efficiency

·Example: A marker using 9.3 yd² of a 10 yd² roll yields 93% efficiency.

·Benchmark:

| Garment Type | Good Efficiency | Elite Efficiency |

| Simple tees | 85–90% | 91–93% |

| Denim jeans | 90–95% | 95–96% |

2.2 Eco & Economic Wins

·Water Use: Every yard of waste denim costs ~50 gal of dye liquor. Cutting 5% more efficiently saves 250 gal per roll!

·Cost Savings: At $8/yd, 0.7 yd of saved fabric is $5.60 saved per pair. At 10,000 pairs, that’s $56,000.

2.3 Brand Impact

·Modern consumers check sustainability claims—report your 94% marker efficiency, and you’re ahead of the pack.

3. Which Types of Markers Are Used in Garment and Denim Production?

Featured Snippet: Manual, multi-ply, and digital markers each serve different scales—manual for custom orders, multi-ply for midsize runs, CAD/CAM for big volumes and precision.

Dive Deeper

3.1 Manual Single-Ply

·When to Use: Prototypes, custom fits under 30 pcs.

·Pros: No software needed.

·Cons: 75–85% efficiency, very labor-intensive.

3.2 Multi-Ply Stacks

·Setup: 5–50 plies stacked; marker drawn on top sheet, then cut all layers at once.

·Efficiency: 88–93%.

·Tip: Use clamped “sandwich” tables to avoid shifting.

3.3 CAD/CAM Digital Nesting

·Software: Gerber AccuMark, Lectra Kaledo, Optitex Nesting.

·How It Works: Auto-nest algorithms place pieces for best fit; user tweaks around defects.

·Efficiency Gains: +3–5% over manual.

3.4 On-Garment Fabric Markers

·Chalk Markers: Temporary, ideal for hand cutting.

·UV Pens: Invisible to naked eye, guides automated cutters.

4. How Do You Make a Marker for Denim Jeans Manufacturing?

Featured Snippet: Input pattern files, define fabric specs, auto-nest with CAD, manually adjust for unique denim traits, then export to PLT/XML for cutting.

Dive Deeper

4.1 Step 1: Pattern Prep

·Confirm file formats (DXF preferred).

·Check all grain lines, notches, seam allowances.

4.2 Step 2: Fabric Specs

·Width & Stretch: Typical widths 58″–60″; record any one-way stretch.

·Defect Zones: Flag areas with selvage flaws or dye inconsistencies.

4.3 Step 3: Nesting

·Auto-Nesting: Let software propose the layout.

·Manual Fine-Tune: Shift pieces to avoid defects or align major seams.

4.4 Step 4: Export & Test

·Export Formats: PLT for plotters, XML/CSV for digital cutters.

·Pilot Cut: Run 6–8 plies to validate alignment; inspect sample jeans for seam fit.

5. How Can You Learn Marker Making via YouTube Tutorials and PDF Guides?

Featured Snippet: Find hands-on CAD marker tutorials on YouTube (e.g., “DenimMasters CAD Nesting”), and grab PDF best-practice guides directly from Gerber or Lectra websites.

Dive Deeper

5.1 Top YouTube Channels

| Channel | Focus | Recency |

| DenimMasters | Lectra & Gerber nesting walkthrough | 2023–2025 |

| PatternLab Pro | Manual vs. digital marker demos | 2024 |

| FactoryInsights | Real-world factory marker audits | 2022–2025 |

5.2 Must-Download PDFs

·Gerber AccuMark Marker Guide (2024): Defect mapping, nesting tips.

·Lectra Digital Nesting Whitepaper (2023): Sustainability data, ROI charts.

5.3 Picking Quality Tutorials

·Look for Factory Footage: Slideshows are fine, but seeing a real machine at work is gold.

·Check Comments & Likes: Community feedback often flags outdated content.

6. Where Can You Find Marker Making Factories and OEM/ODM Suppliers?

Featured Snippet: Marker services span from in-house bureaus at Gerber/Lectra to Shenzhen hubs and specialized OEM/ODM partners like DiZNEW, with MOQs as low as 30 pcs.

Dive Deeper

6.1 In-House Software Bureaus

·Gerber Marker Service: On-demand marker creation via their cloud portal.

·Lectra Service Bureau: Offers digital nesting packages by project.

6.2 Global Tech Hubs

| Region | Specialty

| MOQ |

| Shenzhen | Fast turn-around, mid-volume runs | 100–500 pcs |

| Los Angeles | Custom, designer small batches | 10–50 pcs |

| New York | High-end, bespoke selvedge work | 5–30 pcs |

6.3 DiZNEW OEM/ODM Marker Services

·One-Stop Shop: CAD marker → cutting → QC → packaging.

·Low MOQ: From 30 pcs/style.

·Green Pledge: Recycled marker paper, digital review only.

7. Are There Best Practices for Efficient, Low-Waste Marker Making?

Featured Snippet: Marry digital nesting with manual tweaks, integrate defect mapping, optimize ply counts, and track metrics weekly for >92% fabric utilization.

Dive Deeper

7.1 Blended Workflow

·Auto + Manual: Auto-nest for baseline, then shift for grain and defects.

7.2 Defect Mapping

·Process: Roll scanner → CAD import → auto-exclude bad zones.

·Impact: 25–30% fewer miscuts, 15% less re-dyeing.

7.3 Ply Count Strategy

| Ply Range | Efficiency | Misalignment Risk | Ideal For |

| 5–10 | 90–92% | Low | Prototype, small runs |

| 20-30 | 92–95% | Medium | Standard bulk orders |

| 40–50 | 93–96% | High | High-volume denim |

7.4 Continuous Improvement

·KPIs: Efficiency %, miscut rate per 1,000 pcs, setup time

·Feedback Loop: Weekly marker reviews; tweak nesting rules; train operators on best layouts.

1.What markers to use on jeans?

Opt for alcohol-based fabric markers or acrylic paint pens on jeans, as they resist fading and washing, while removable chalk markers offer temporary designs; always pre-wash denim and heat-set permanent marks for long-lasting customization.

2.What is a good substitute for tailor's chalk?

Common tailor's chalk substitutes include soap slivers (budget-friendly, washes easily), vanishing fabric markers (precise lines that disappear with heat), and water-soluble pencils (ideal for light fabrics) - all providing temporary fabric markings for sewing projects without residue.

3.What do tailor use to mark fabric?

Tailors commonly use tailor's chalk (reusable, visible on dark fabrics), vanishing fabric markers (air/water-soluble for precision), tracing wheels with dressmaker's paper (pattern transfers), and water-soluble pens (gentle on delicate textiles) – always test markings first and remove with ironing/spraying for professional results.

4.What to use as a fabric marker?

Effective fabric markers include water-soluble pens (ideal for light fabrics), tailor's chalk (temporary marks on wool/denim), vanishing ink (disappears in 24-48 hours), and acrylic paint pens (permanent on jeans) – always test on scrap fabric and remove markings with water, heat, or rubbing alcohol for flawless results.

Conclusion

Mastering marker making is your secret weapon for crafting top-quality denim jeans while slashing waste, cutting costs, and boosting your sustainability creds. By understanding what a marker is, measuring and improving your efficiency, choosing the right marker type, and blending digital auto-nesting with hands-on tweaks, you can consistently hit 92–96% fabric utilization. Leverage online tutorials and PDF guides to sharpen your skills, partner with trusted OEM/ODM suppliers like DiZNEW for low-MOQ runs, and keep a close eye on your metrics through regular audits.

Ready to transform your denim production? Reach out to DiZNEW today for a custom marker solution that fits your design vision, order size, and green goals—let’s cut smarter and make every yard count!