Can Anyone Help Me Create a Jean Tech Pack? An Expert Guide for Designers & Brands

- Share

- Issue Time

- Aug 9,2025

Summary

Discover expert tips for creating a jean tech pack. This comprehensive guide is perfect for designers and brands looking to streamline their denim production process.

Imagine you’ve just sketched the perfect pair of vintage-inspired, selvedge denim jeans—mid-rise, snug through the thigh, tapering neatly to the ankle, with that signature whisker fade and custom pocket stitch.

You’re bursting with ideas, but unless your manufacturer gets every detail spot-on, you might end up with a totally different product—or worse, a costly batch of rejects. That’s where a jean tech pack comes in: the secret weapon for designers, small brands, and production professionals who need to translate creative vision into flawless garments.

A jean tech pack is a comprehensive blueprint that communicates every design, measurement, material, and construction detail needed to produce a pair of jeans. It typically includes technical flats, measurement specs, fabric and trim information, sewing instructions, and finishing guidelines. A well-crafted tech pack reduces production errors, streamlines sampling, and ensures consistency across sizes and styles, making it indispensable for anyone serious about launching or scaling a denim line.

Before you know it, you’re researching “How to make a tech pack for clothing?” and “Who can create a tech pack for me?”—only to be overwhelmed by conflicting advice. But what if you could follow a clear, step-by-step roadmap developed by a factory with over 20 years of denim expertise?

Picture yourself in DiZNEW’s design studio in Dongguan: fabric swatches spread across the table, digital measurements imported directly from a 3D body scan, and an experienced tech-pack specialist reviewing every line of your document. Intrigued? Let’s dive into exactly what a jean tech pack is, why it matters, and how you can create—or commission—one that leads straight to production success.

What Exactly Is a Jean Tech Pack and Why Is It Essential?

A jean tech pack is a detailed document that serves as the single source of truth for manufacturing your denim design. It outlines technical sketches (flats), precise measurements & grading rules, material & trim specifications, construction methods, and finishing instructions. By providing clear, standardized information, a tech pack minimizes misunderstandings, speeds up sampling, and ensures consistent quality across multiple production runs and sizes—making it an indispensable tool for designers and brands.

At its core, a jean tech pack bridges the gap between creative vision and factory execution. Think of it as the instruction manual any manufacturer needs to transform your concept into a real garment. Without one, you’re relying on vague emails, blurry photo references, or verbal descriptions—an invitation to costly errors and delays.

Why Every Denim Line Needs a Tech Pack

First impressions matter in fashion. A poorly executed sample can derail a brand launch, erode buyer confidence, or trigger expensive re-runs. A complete tech pack addresses:

Clarity: Ambiguous instructions on pocket shape or wash treatments lead to inconsistent results.

Accuracy: Precise measurements for waist, hip, thigh, knee, and leg opening ensure proper fit across sizes.

Consistency: Standardized specs guarantee that each pair in a batch meets your quality criteria.

Efficiency: Well-structured docs reduce back-and-forth by up to 50%, accelerating sampling and production.

Who Uses Tech Packs?

• Independent designers and startups who lack in-house patternmaking teams rely on tech packs to communicate with offshore factories.

• Mid-size brands need them to streamline communication between design, production, and quality-control teams.

• High-end labels use them to maintain craftsmanship standards—think selvedge denim details, beveled rivets, or custom embroidery.

Key Stakeholders and Their Roles

• Designer/Product Developer: Drafts creative direction and initial measurements.

• Patternmaker: Converts sketches into digital or paper patterns, referencing tech-pack measurements.

• Tech-Pack Specialist: Finalizes every specification, ensuring nothing is left to assumption.

• Factory Production Team: Executes the build based on the tech pack, from fabric cutting to wash processes.

• Quality Assurance: Verifies finished garments match the tech pack’s specs.

In today’s competitive market, brands that skip the tech-pack stage often pay the price in sample re-makes, shipment delays, and missed sales windows. By treating your tech pack as a strategic asset—rather than a bureaucratic hurdle—you safeguard your vision, reputation, and bottom line.

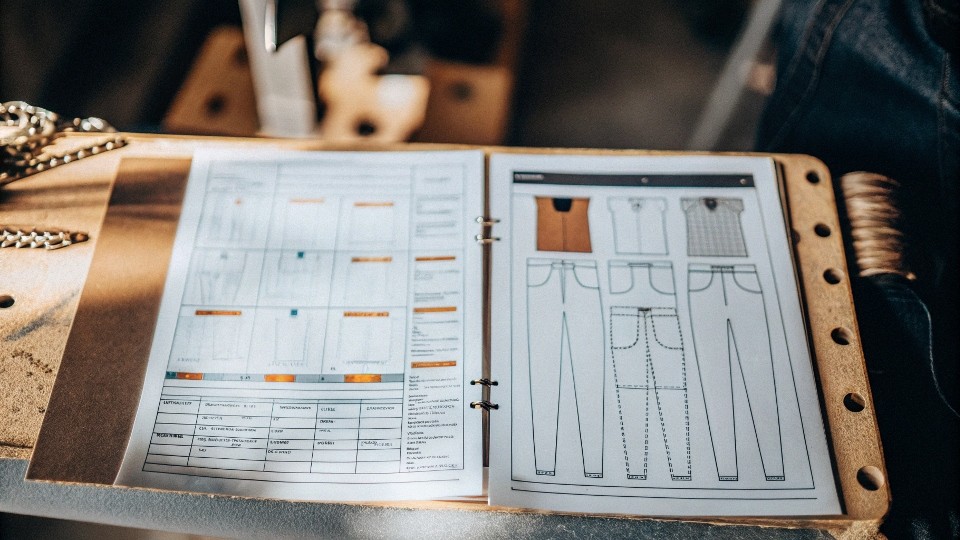

Which Key Sections Should Your Jean Tech Pack Include?

A comprehensive jean tech pack typically contains five core sections: 1) Technical Sketches & Flats illustrating front, back, and detail views; 2) Measurement Specs & Grading Rules covering all critical points of measure; 3) Material, Trim & Hardware Details listing denim weight, composition, zippers, buttons, and labels; 4) Construction Details & Sewing Instructions specifying stitch type, seam allowances, and reinforcing techniques; and 5) A Step-by-Step Guide on assembling the tech pack itself.

A robust tech pack feels like an encyclopedia of your garment—every nuance spelled out. Let’s break down each section:

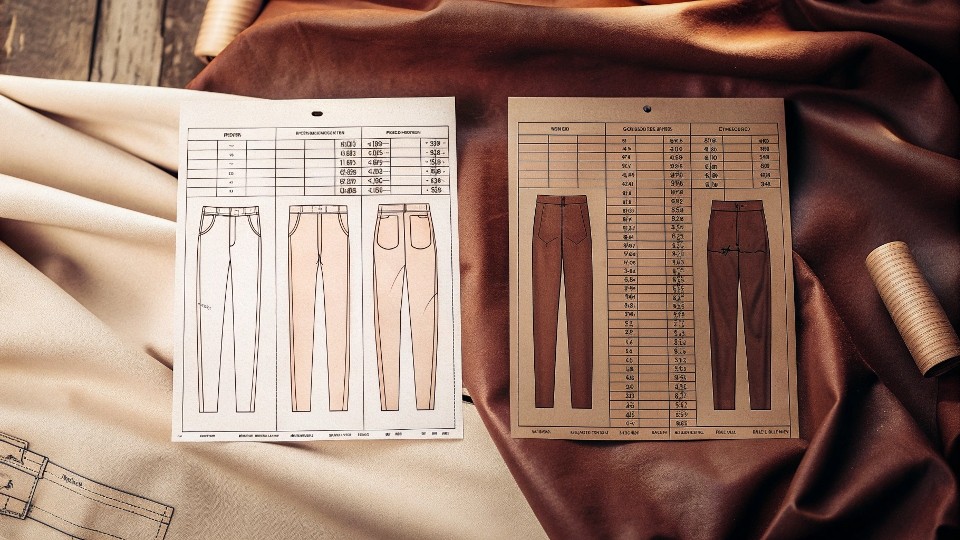

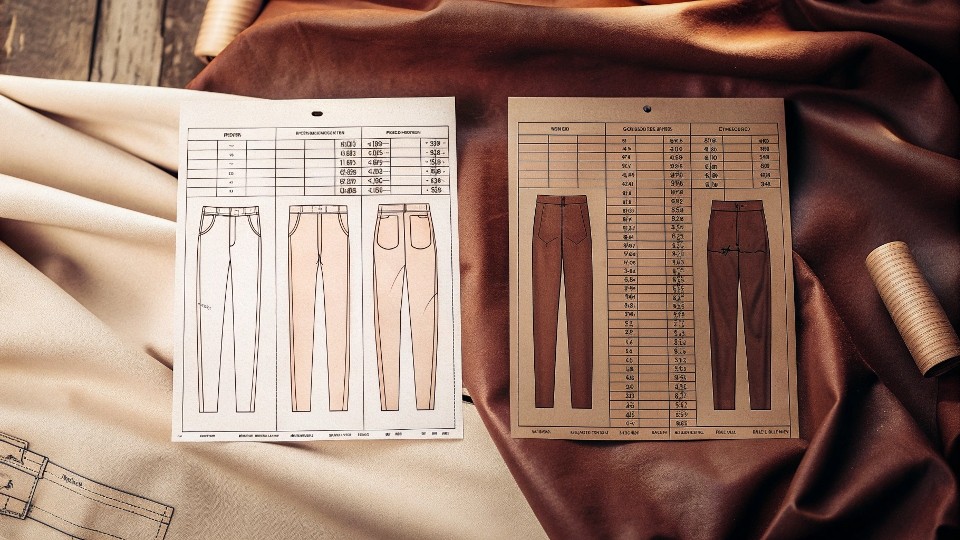

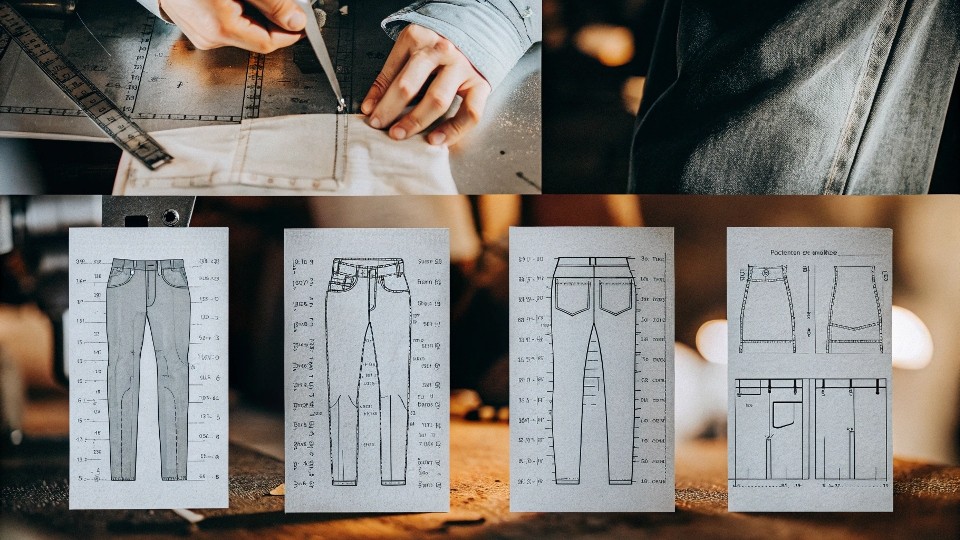

Technical Sketches & Flats

• Hand-drawn or digital flats show a clean line-drawing from multiple angles (front, back, side, top-view waistband).

• Detail call-outs zoom in on pocket shapes, belt-loop placement, rivet positions, and signature design elements (e.g., stacked cuffs or whisker fades).

• Annotations highlight special requests like asymmetrical hems or exposed selvedge edges.

Measurement Specs & Grading Rules

• Spec sheet includes points of measure: waist, front-rise, back-rise, hip, thigh (8” below crotch), knee (center), leg opening, inseam, outseam.

• Grading rules define how each measurement changes between sizes (e.g., +1” waist per size, +0.5” thigh).

• Tolerance fields (±0.2”) set acceptable deviation ranges—critical for quality control.

Material, Trim & Hardware Details

• Fabric breakdown: denim weight (12 oz vs. 14 oz), fiber content (100% cotton vs. stretch blends), dyeing method (sanforized, rope-dyed).

• Trims: zipper style (metal vs. molded plastic), button type (brass tack, shank button), pocket lining material.

• Labels & packaging: leather patch size, hang tag specs, polybag dimensions.

Construction Details & Sewing Instructions

• Stitch types (chainstitch vs. lockstitch), seam allowances (5/8”, 1/2”), topstitching thread count and color.

• Reinforcements: bartacks at stress points, pocket-mouth rivets, waistband interfacing.

• Edge finishes: raw hem, blind stitch, overlocked seam.

Step-by-Step Guide: How to Create a Clothing Tech Pack

1.Gather reference images, sketches, and inspirational pieces.

2.Draft clear technical flats in CAD or Illustrator.

3.Compile a spec sheet with exact measurements and grading increments.

4.Source fabric swatches and trim samples; document supplier details.

5.Write detailed construction notes and attach wash-process guidelines.

6.Review with patternmaker and factory tech-pack specialist before finalizing.

By organizing your tech pack into these five pillars, you ensure nothing falls through the cracks—and give your manufacturer the precise roadmap needed to bring your denim vision to life.

How Do You Capture Precise Measurements, Construction Details, and Grading Specs?

Capturing accurate measurements and grading rules requires a systematic process: begin with a detailed fit sample or sloper, use a calibrated tape or digital measuring tools to record every point of measure, then apply standardized grading increments across sizes. Pair manual methods with 3D body-scanning data for near-perfect precision. Document tolerance bands (e.g., ±0.2”) and reference the measurement annotation key in your tech pack to maintain consistency and quality control.

Measurements are the backbone of fit—and fit sells. Inaccuracies ranging from a loose waistband to a baggy knee can lead to negative reviews, returns, and wasted production runs. Here’s how to nail your specs:

Manual Measurement Techniques

• Use a retractable measuring tape with 1 mm increments.

• Lay the fit sample flat on a rigid table, smoothing out wrinkles without stretching the fabric.

• Refer to a standardized measuring guide—many factories provide templates with exact landmarks for each point of measure.

• Record each measurement three times for consistency, averaging the results.

Digital & 3D Scanning

• High-resolution 3D body or sample scanners capture every contour of a human form or finished garment.

• Scans export directly into CAD software, reducing manual entry errors.

• Some systems auto-generate spec sheets and highlight anomalies outside set tolerances.

Grading Rules: Turning One Size into Many

• Grading involves proportionally increasing or decreasing key measurements across size ranges.

• Common denim grading increments: waist (+1”), hip (+1”), thigh (+0.75”), knee (+0.5”), leg opening (+0.5”).

• Grading blocks must adapt to special cuts (e.g., baggy jeans require wider thigh increments).

• Always test your grading rules with a fit sample in a mid-range size before bulk production.

Annotating Construction Details

• Label each measurement on your technical flats with leader lines and consistent numbering.

• Define seam allowances, topstitching intervals, and thread counts in a construction key.

• Include references to specific sewing machines or stitch types—chainstitch for vintage appeal, lockstitch for durability.

Tolerance & Quality Control

• Tolerance bands (e.g., ±0.2” for critical measures, ±0.3” for secondary) set quality thresholds.

• Factories perform AQL (Acceptable Quality Level) inspections on pre-production samples and bulk orders.

• Discrepancies trigger corrective actions documented in tech-pack revision logs.

By combining manual diligence with digital innovation, and by clearly annotating every spec and tolerance, you give your manufacturer the confidence to produce jeans that fit exactly as you intended—size after size.

What’s the Best Way to Specify Fabrics, Trims, Washes, and Finishes?

Specify denim fabrics by weight (8–16 oz), composition (100% cotton vs. stretch blends), dyeing method (rope vs. slasher dyed), and origin (Japanese selvedge vs. Chinese cone mill). Document trims—zipper brand, rivet finish, button type—with part numbers. Detail wash processes (enzyme, stonewash, bleach, laser) including chemical concentrations, cycle times, and desired visual effects. Use photo references and lab reports to ensure your manufacturer replicates your intended look and handfeel precisely.

Fabric & Fiber Content

• Weight: Light (8–10 oz), mid-weight (10–12 oz), heavyweight (12–16 oz). Heavier denim offers structure, lighter is ideal for summer styles like denim shorts.

• Composition: 100% cotton for traditional rigid feel; 98/2 or 97/3 cotton–elastane blends for stretch and comfort.

• Dyeing: Rope-dyed yarns yield deep indigo saturation and natural fading; slasher-dyeing is more cost-effective but offers less depth.

Finishes & Handfeel

• Sanforization: Reduces shrinkage to under 1%.

• Biowash/enzyme wash: Softens fabric and creates vintage softness.

• Coatings: PU or wax coatings add water resistance or a glossy surface.

• Hand scraping and resin finishes deliver stiff, paper-like textures.

Trims, Hardware & Notions

| Trim Type | Common Options | Notes |

Zippers | YKK #5 metal, Vislon plastic | Metal for authenticity; plastic for lightweight comfort |

| Buttons | Brass tack, shank, snap | Shank buttons allow cleaner waistband finish |

| Rivets | Antique copper, silver | Decorative and reinforcing; choose color to complement wash |

| Labels & Tags | Leather patch, woven label | Embossed leather for premium feel; woven for brand storytelling |

Wash & Distressing Processes

1.Enzyme wash: Uses cellulase to abrade fibers, yielding mellow tones.

2.Stonewash: Pumice stones tumble with jeans to break fibers, creating random fades.

3.Bleach wash: Chlorine or potassium permanganate for high-contrast highlights.

4.Laser treatments: Precision whiskers and honeycombs without water or chemicals—for eco-friendly distressing.

Documenting Wash Recipes

• Chemical type and concentration (e.g., 0.5% CMC enzyme).

• Cycle time (minutes), temperature (°C), and mechanical action level.

• Rinse protocols—number of water changes, spin speeds, drying method (tumble vs. flat).

• Target color grade measured by spectrophotometer (Lab values).

Takeaway

The more specific you are—down to supplier names, part numbers, and process metrics—the less room for interpretation and the higher the likelihood your manufacturer delivers exactly what you envisioned. Always include high-quality photos of wash references and, when possible, a small lab-tested fabric swatch.

How Can You Partner with a Manufacturer (Like DiZNEW) to Finalize Your Tech Pack?

Partnering with a factory like DiZNEW means tapping into 20+ years of denim R&D, low MOQs (30 pieces), and full OEM/ODM capabilities. You can commission a tech pack from in-house specialists, negotiate cost-effective rates, and have direct access to Korean rope-dyed selvedge, stretch blends, and custom wash labs. DiZNEW refines your tech pack through prototype sampling, grading adjustments, and AQL inspections—ensuring your jeans, shorts, or jackets meet your brand’s highest standards.

When you choose to work with an experienced partner such as DiZNEW, you unlock a seamless pathway from concept to finished garment. Here’s how to leverage that expertise:

Can I Pay Someone to Make a Tech Pack for Me?

Absolutely. Factories and independent tech-pack specialists offer drafting services. At DiZNEW, our tech-pack team works directly from your sketches, inspiration boards, or rough notes. We charge a fixed fee—typically $200–$500 per style depending on complexity—which covers:

• Initial consultation and design brief analysis

• Creation of technical flats (front, back, details) in CAD

• Compilation of spec sheets, grading rules, and tolerance bands

• Material and trim sourcing recommendations

• One round of revisions based on your feedback

Investing in professional tech-pack development pays dividends by reducing miscommunication and sample-round costs.

How Much Does It Cost to Get a Tech Pack Made?

• Basic design house/ freelancer: $150–$300 per style

• Specialized denim factory (OEM/ODM): $300–$600 per style, often bundled with prototype fees

• Full service (design, patternmaking, tech pack, sample sewing): $600–$1,200+ per style

At DiZNEW, we offer transparent, tiered pricing: smaller runs (30–100 pcs) carry slightly higher unit tech-pack budgets, while larger runs unlock discounts. Remember to factor in sample-making costs (roughly $50–$100 per sample) and shipping for swatches or lab dips.

Can You Get Jeans Custom Made?

Yes. DiZNEW excels at custom denim—from plus sizes (1X–5X) to baggy, stacked, skinny, straight, jogger jeans, denim jackets, and more. Here’s what our customization process looks like:

1.Concept & Tech-Pack Development: We refine your tech pack until it’s factory-ready.

2.Prototype Sampling: Within 10–15 days, receive a physical sample for fit, finish, and wash approval.

3.Fit Review & Revisions: Up to three rounds of adjustments ensure perfect alignment with your brand vision.

4.Bulk Production: Minimum Order Quantity (MOQ) of just 30 pieces per style—flexible enough for indie brands.

5.Quality Assurance & Packaging: AQL inspections, custom hang tags, labels, and e-commerce–ready polybags.

6.Logistics Support: Consolidated shipments from our Dongguan hub direct to your US warehouse or drop-ship location.

By leveraging our R&D lab, washhouse capabilities, and in-house pattern and sampling teams, you get end-to-end support that de-risks your production timeline and delivers consistent, on-brand denim.

Conclusion & Next Steps

Crafting a flawless jean tech pack is both an art and a science—and it’s your blueprint for manufacturing success. From meticulously annotated technical flats to exact wash-process specifications, every detail counts.

Whether you’re a solo designer, a fast-growing indie label, or a high-end brand looking for OEM/ODM partners, DiZNEW’s 20+ years of denim mastery, low MOQs, and comprehensive in-house services make us the go-to factory for custom jeans, denim jackets, shorts, and more.

Ready to bring your denim vision to life with zero guesswork? Contact DiZNEW today for a detailed quote on tech-pack development, prototyping, and full-scale production. Let’s turn your sketches into staple pieces that fly off the shelves—and cement your brand’s reputation for quality and innovation. Your perfect pair of jeans is just a tech pack away.

Classic straight jeans with bold contrast stitching in light blue, dark blue, and black — made for standout collections.

Speckled with galaxy-inspired spray dots, these loose-fit denim pants blend cosmic vibes with urban edge.

Classic art meets contemporary denim—Romantic oil painting print jeans for the bold and cultured wardrobe.

Statement cargo jeans with stacked fit, bleach fade, and heavy-duty pockets — perfect for streetwear labels.